Wide gap welding method and welding part

A welding method and wide-gap technology, applied in welding medium, welding equipment, welding equipment, etc., can solve the problems of poor strength and prone to cracks at the weld, and achieve the effect of improving strength, good quality and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

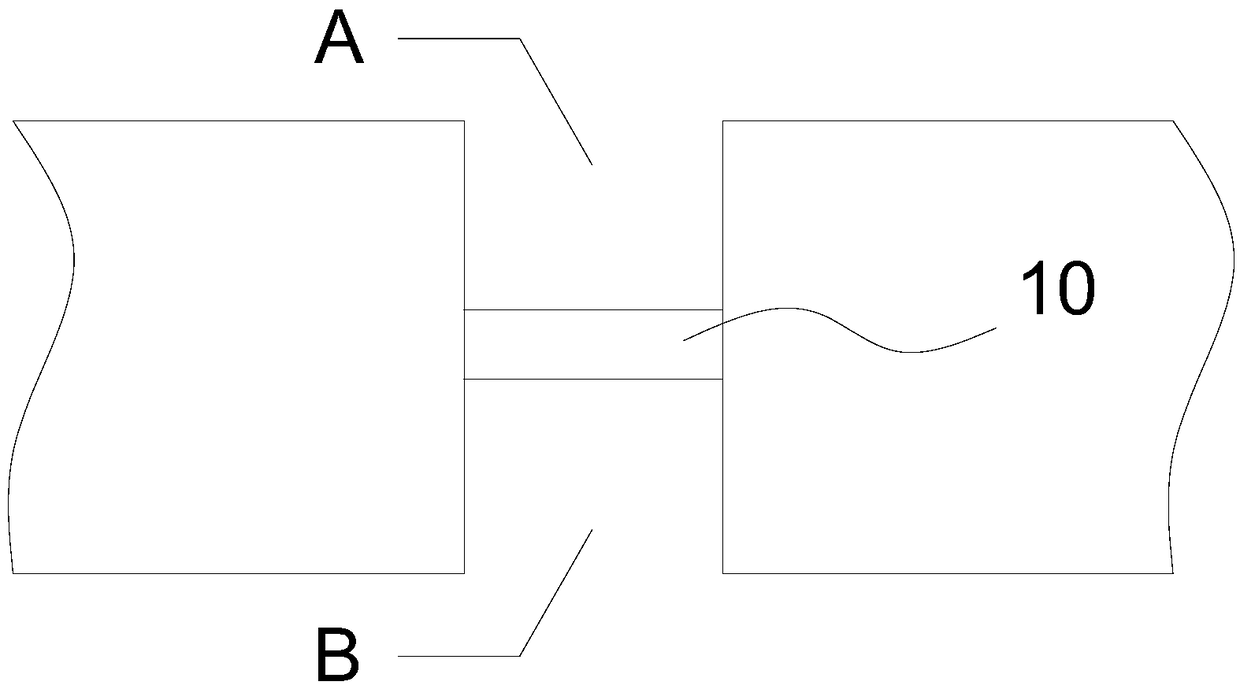

[0040] A wide gap welding method, comprising the steps of:

[0041] Clean the parts to be welded with a groove depth of 10mm and a welding width of 5mm, wash off the dirt on the surface and dry it, and use sandpaper to grind off the oxide layer on the surface, and ensure that the groove and the distance from the groove are 40mm There is no oil stain inside, and the surface of the backing plate with a thickness of 3mm that is the same as the material to be welded is cleaned so that the surface of the backing plate is free of oil stains. After the weldment is cleaned up, the backing plate is welded in the middle of the groove. The welding method adopts metal gas shielded welding, and the various parameters during welding are the same as the following welding contents.

[0042] After the backing plate is welded, preheat the part to be welded to 210°C. Power up the welding tool, use MIG shielded arc welding, and weld the grooves on both sides of the backing plate in turn. During ...

Embodiment 2

[0045] A wide gap welding method, comprising the steps of:

[0046]Clean the parts to be welded with a groove depth of 50mm and a welding width of 9mm, wash off the dirt on the surface and dry them, and use sandpaper to grind off the oxide layer on the surface, and ensure that the groove and the distance from the groove are 40mm There is no oil stain inside, and the surface of the backing plate with a thickness of 15mm that is the same as the material to be welded is cleaned so that the surface of the backing plate is free of oil stains. After the weldment is cleaned up, the backing plate is welded in the middle of the groove. The welding method adopts metal gas shielded welding, and the various parameters during welding are the same as the following welding contents.

[0047] After the backing plate is welded, preheat the part to be welded to 230°C. Power up the welding tool, adopt MIGA welding, and weld the grooves on both sides of the backing plate in turn. During the weld...

Embodiment 3

[0050] A wide gap welding method, comprising the steps of:

[0051] Clean the parts to be welded with a groove depth of 20mm and a welding width of 6mm, rinse off the dirt on the surface and dry it, and use sandpaper to grind off the oxide layer on the surface, and ensure that the groove and the distance from the groove are 40mm There is no oil stain inside, and the surface of the backing plate with a thickness of 5mm that is the same as the material to be welded is cleaned so that the surface of the backing plate is free of oil stains. After the weldment is cleaned up, the backing plate is welded in the middle of the groove. The welding method adopts metal gas shielded welding, and the various parameters during welding are the same as the following welding contents.

[0052] After the backing plate is welded, preheat the part to be welded to 220°C. Power up the welding tool, use MIG shielded arc welding, and weld the grooves on both sides of the backing plate in turn. During...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com