Online grinding quality control system and method based on laser sensing

A laser sensing and control system technology, applied in the direction of automatic grinding control device, workpiece feed movement control, manufacturing tools, etc., can solve problems such as low efficiency, inability to adjust grinding parameters, and inability to monitor grinding quality online in real time , to achieve the effect of reducing the cost of use, simple structure and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

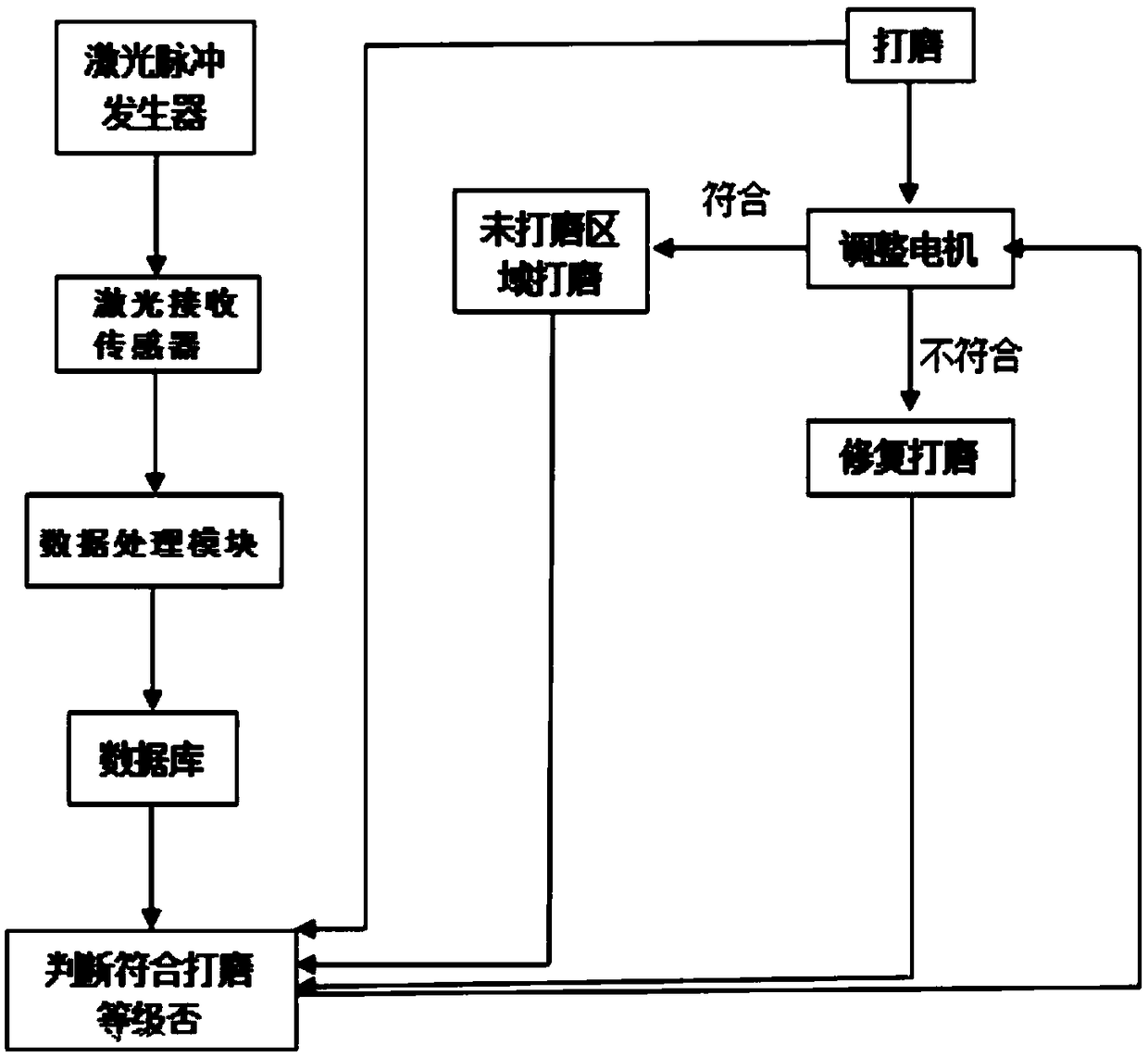

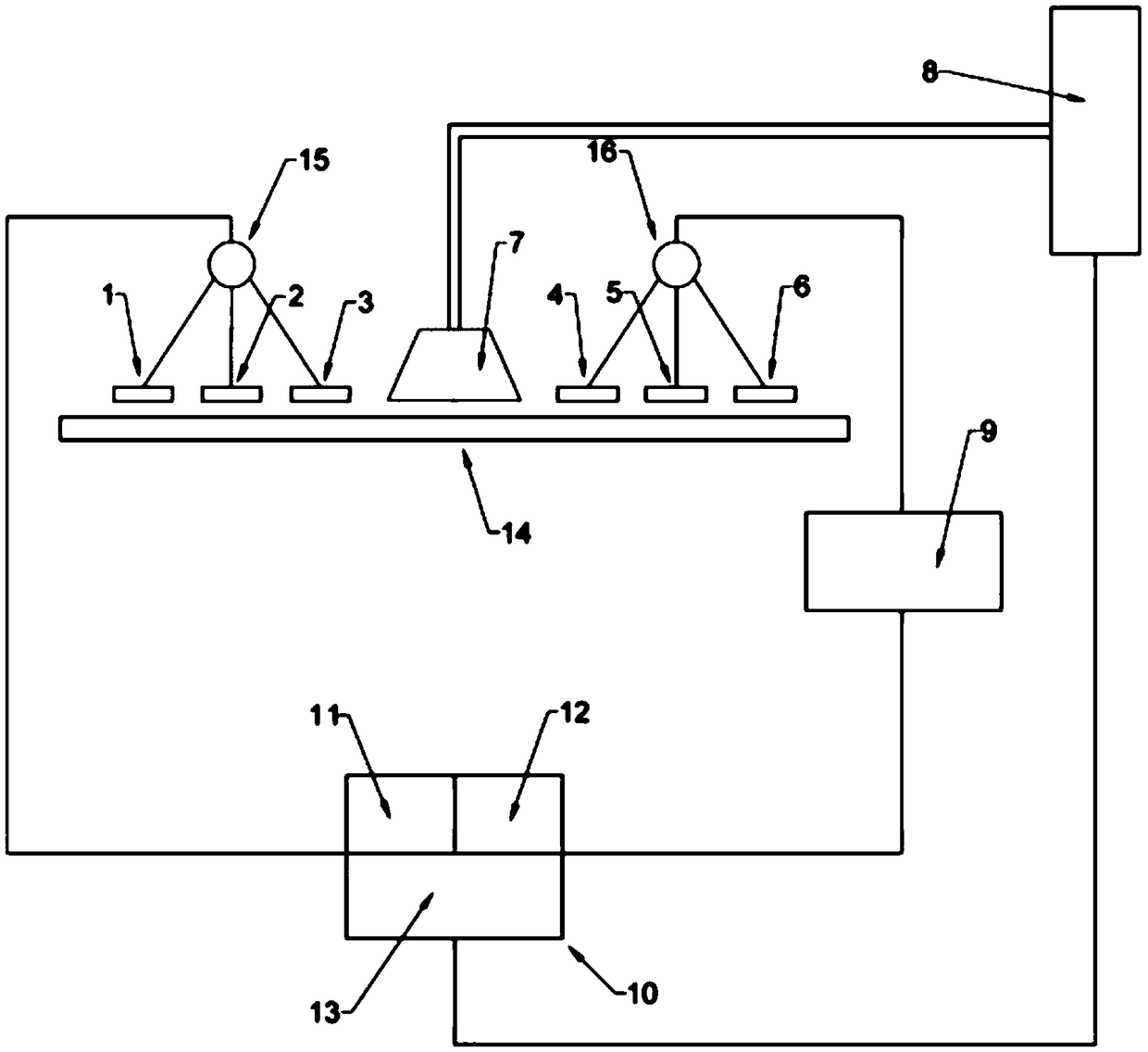

[0034] Such as figure 1 As shown, an online grinding quality control system based on laser sensing includes a grinding module, and the grinding module includes grinding heads 1, 2, 3, 4, 5, 6, and the grinding heads 1, 2, 3, 4, 5, 6 electrically connected spatial six-degree-of-freedom motors 9 and gearboxes 11, 12 connected to the main shafts 10, 11 of the spatial six-degree-of-freedom motors 9, the grinding heads 1, 2, 3, 4, 5 , 6 are installed on the output shafts 15,16 of the gearboxes 11,12, the online grinding quality control system also includes a roughness measurement module 7 for measuring the roughness of the grinding plane 14 just polished, the Roughness measurement module 7 comprises laser pulse generator 8, the grating of adjustable luminous flux and laser receiving sensor; Electrically connected, the grinding module, the roughness measurement module 7 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com