A mold rapid cooling and rapid heating device using a semiconductor refrigerator and a phase change material

A phase change material and semiconductor technology, applied in the field of molding and manufacturing, can solve problems such as shortening molding cycle, increasing energy consumption and production cost, product weld lines, orange peel, fine lines, etc., to improve surface quality, eliminate weld lines and effect of orange peel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

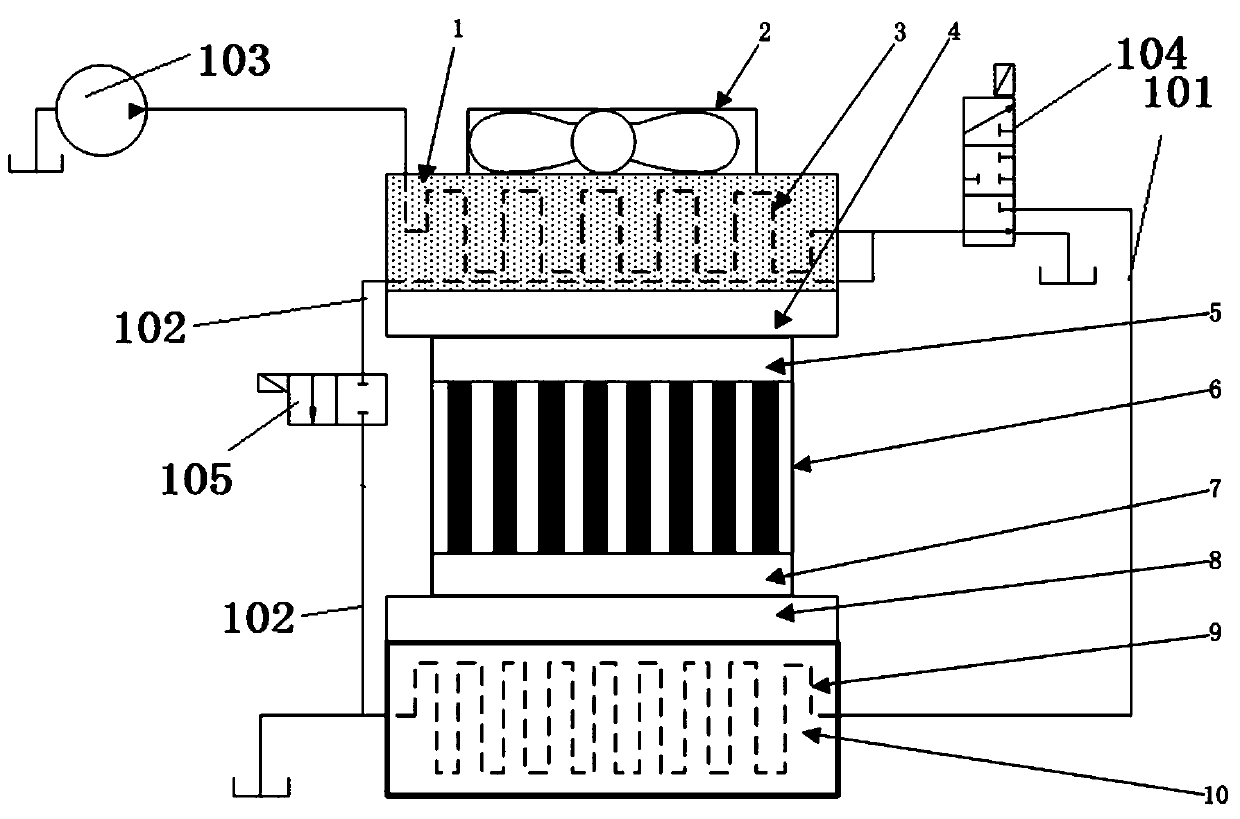

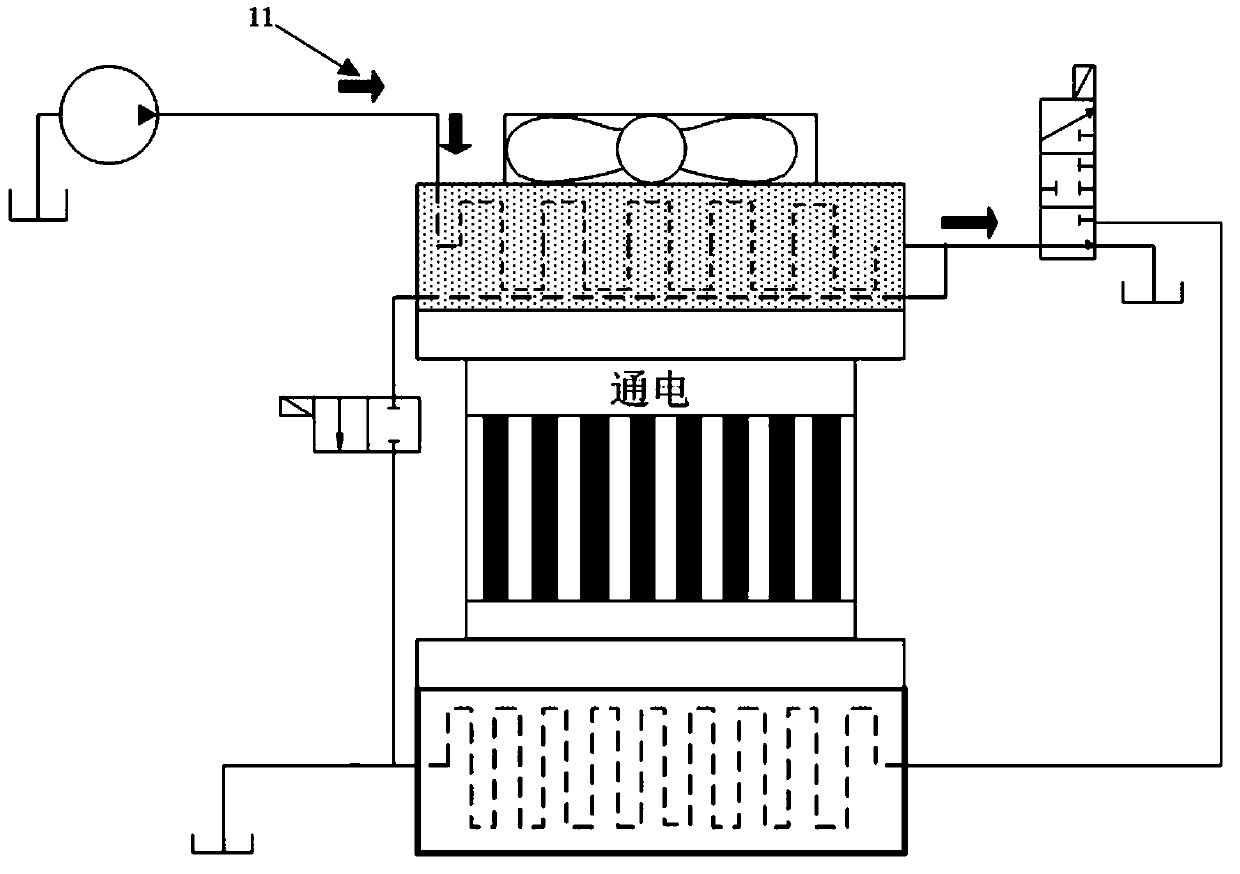

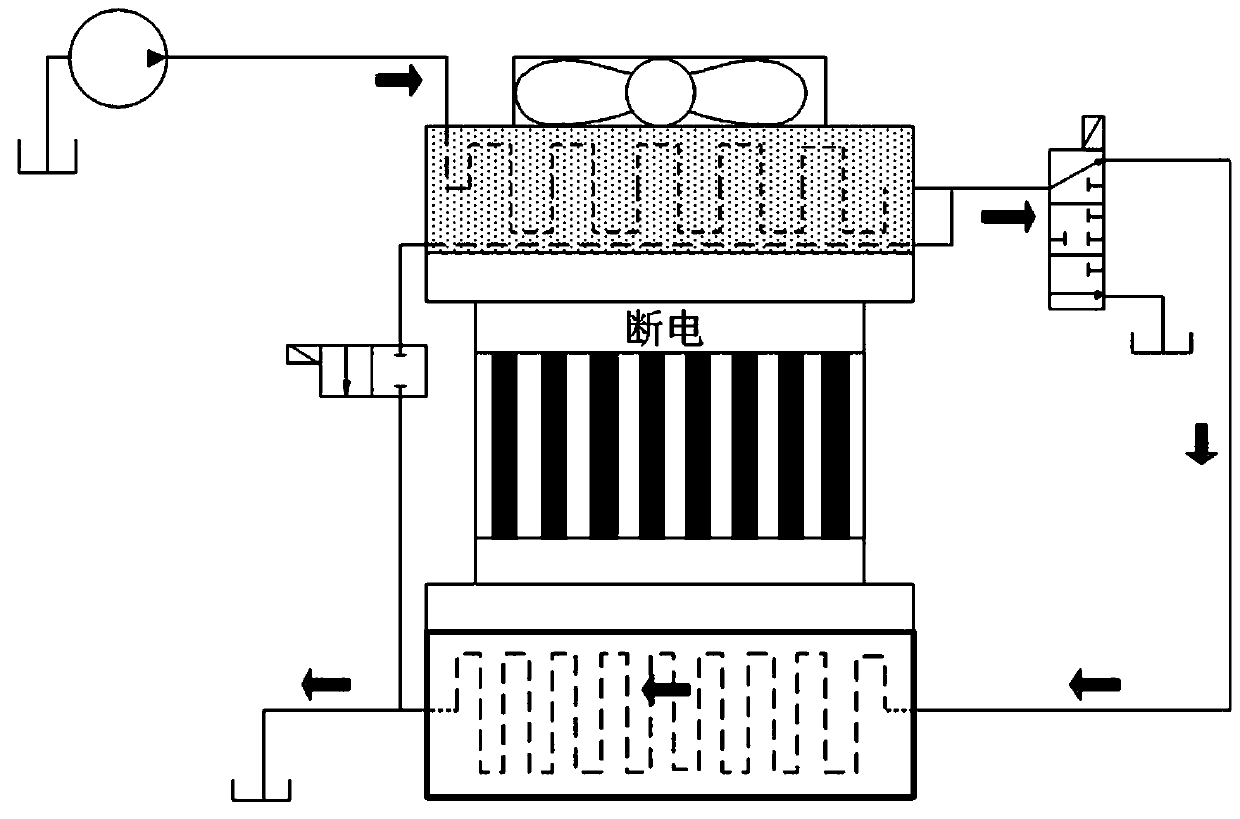

[0036] Such as Figure 1-11 As shown, a rapid cooling and rapid heating device for a mold using a semiconductor refrigerator and a phase change material is used to perform rapid cooling and rapid heating temperature adjustment operations on the mold 10. The rapid cooling and rapid heating device includes a control module, a mold heater, and a coolant. The mold channel 9, the phase change cold storage 1, the cooling liquid cooling tube 3, the semiconductor refrigerator 6; the phase change cold storage contains the phase change components; the cooling liquid mold channel is provided at the mold 10; The cooling liquid cooling pipe is arranged at the phase change cold storage and communicates with the cooling liquid mold channel through the controllable valve 104; the hot end of the semiconductor refrigerator is connected with the mold, and the cold end is connected with the phase change cold storage; When the mold is subjected to rapid heating operation, the hot end of the semicon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com