Insulation tank car insulation system

An insulation system and technology for tank cars, which are applied to tank cars, transport passenger cars, railway car body parts, etc. Weight, the effect of reducing the heat leakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

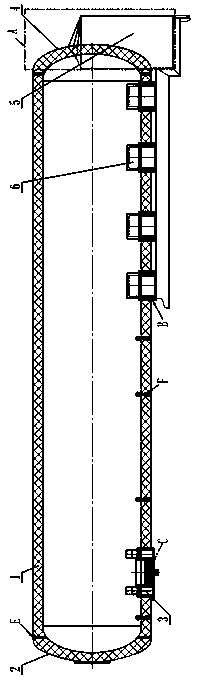

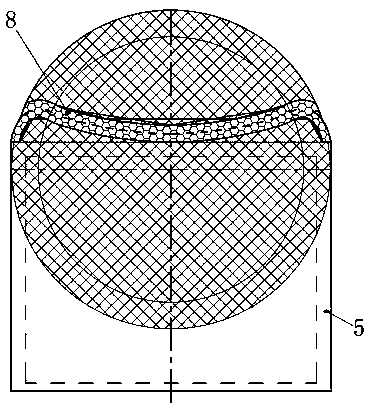

[0037] Such as Figure 1-Figure 8 , Figure 12 , Figure 13 As shown, the heat preservation tank car heat preservation system includes a tank body heat preservation structure sandwiched between the inner and outer tank bodies and a secondary heat preservation structure connected with the tank body heat preservation structure. The secondary thermal insulation structure consists of the secondary thermal insulation structure A of the tank body head, the secondary thermal insulation structure B of the V-shaped beam of the tank body, the secondary thermal insulation structure C of the tank traction plate, and the thermal insulation structure of the tank body located at the metal connector of the tank body. Structure E composition.

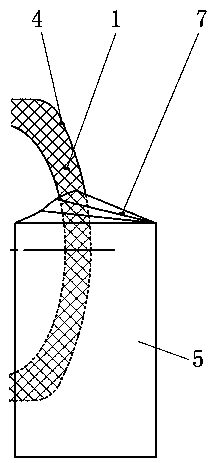

[0038] Among them, see figure 2 , image 3 The secondary heat preservation structure A of the tank head includes a rear head body 4 and a valve box, the valve box surrounds the middle and lower part of the rear head body 4, and the valve box is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com