Adjustable automated manual hydraulic execution mechanism

An actuator and adjustable technology, applied to valve details, mechanical equipment, engine components, etc., can solve problems such as failure to work normally, low reliability, single function, etc., and achieve high volumetric efficiency and reliability, good sealing performance, Oil circuit built-in effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

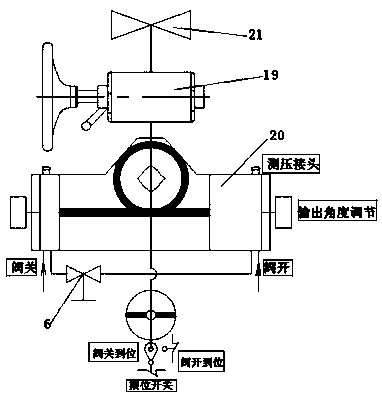

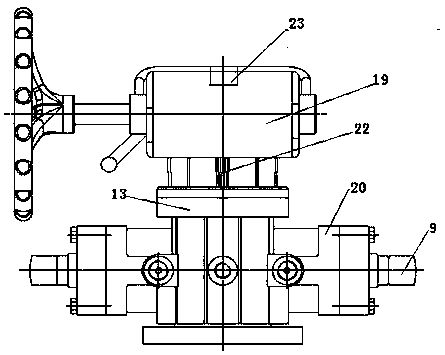

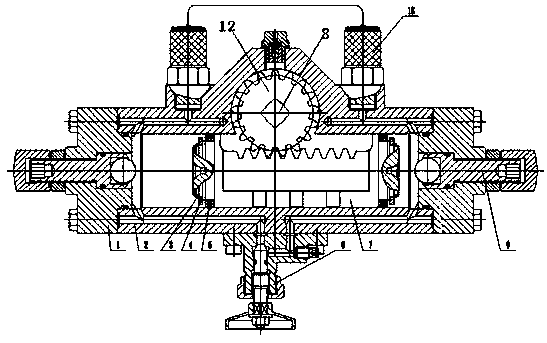

[0014] The device includes a controlled valve 21 and a hydraulic actuator 20 respectively connected with a clutch type valve driving device 19, such as Figure 1-Figure 4 As shown, the hydraulic actuator 20 includes a hollow housing 2 with a left and right penetrating structure, and the left and right ends of the housing 2 are provided with end covers 1, and an output angle adjustment assembly 9 is provided on the outside of the end cover 1. The housing 2 is provided with a rack 7, and both ends of the rack 7 are provided with a "Y"-shaped sealing ring 5, a positioning ring 4 is provided on the outside of the "Y"-shaped sealing ring 5, and a retaining ring 3 is provided on the outside of the positioning ring 4 , the upper end of the rack 7 is provided with a gear shaft 12 meshing with it, the upper end of the gear shaft 12 is provided with a tile shaft 14, the rear end of the gear shaft 12 is provided with a connecting rod 15, and the rear end of the connecting rod 15 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com