Fractured rock mass intelligent grouting measurement and control system and implementation method thereof

A technology of cracked rock mass and measurement and control system, which is applied in the field of rock mass grouting, can solve the problems of lack of accurate identification of the grout diffusion range, and achieve the effects of ensuring safety and high efficiency, reducing waste of grout materials, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

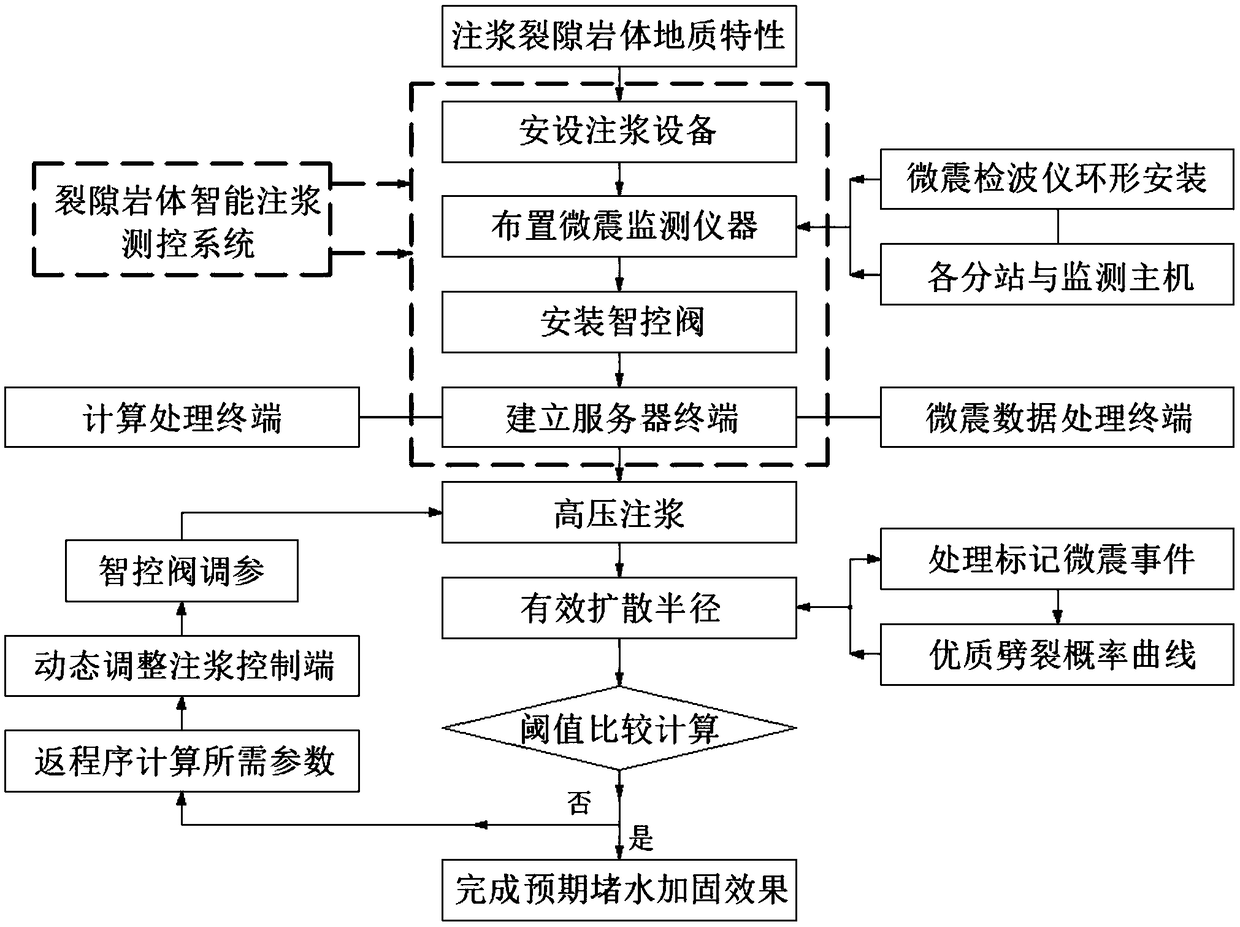

[0036] The implementation method of the above-mentioned intelligent grouting measurement and control system for cracked rock mass is characterized in that it includes the following steps:

[0037] Step 1, according to the geological conditions of the cracked rock mass 1 grouting project, the grouting device is installed in place according to the design process to meet the engineering requirements, using the layout of the grouting holes 9, row spacing, rock mass crack parameters and grouting pressure, The grouting flow rate is to preliminarily determine the preset diffusion range R of the grouting slurry.

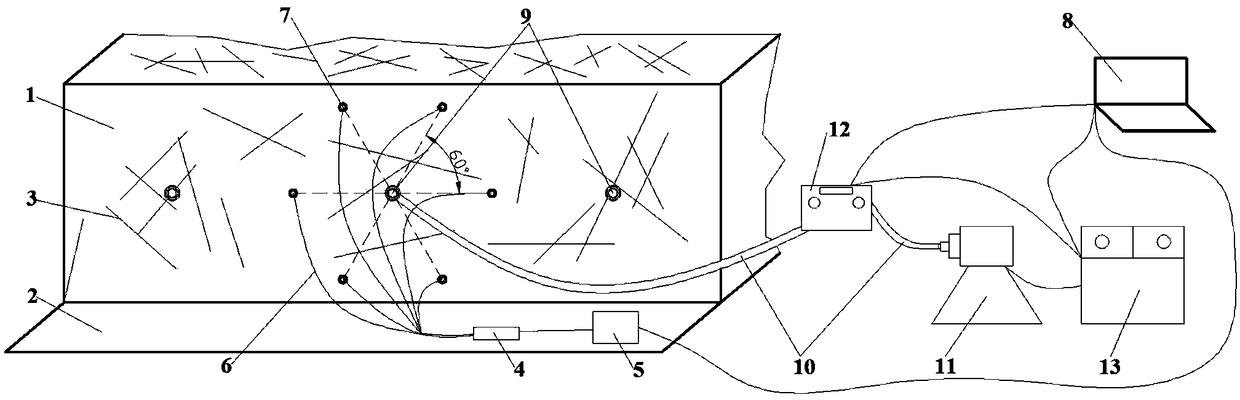

[0038] Step 2, a microseismic monitoring system is arranged before the grouting project is implemented: a microseismic geophone 7, a signal transmission line 6, a data substation 4, an underground monitoring host 5, and a server 8.

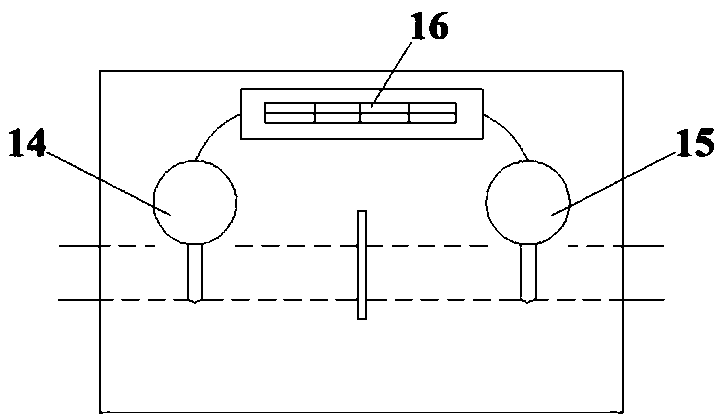

[0039] Step 3, install the intelligent control valve 12 to connect the grouting control terminal 13 to the terminal of the server 8, and set th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com