Internal cooling ventilation system adopting full-air-cooling cooling mode for large synchronous phase regulator

A cooling method and internal cooling technology, applied in the direction of cooling/ventilation devices, electromechanical devices, magnetic circuit rotating parts, etc., can solve the problems of high operating cost, low failure rate, complex structure, etc., to improve cooling efficiency and effect, The effect of reducing the workload and the number of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

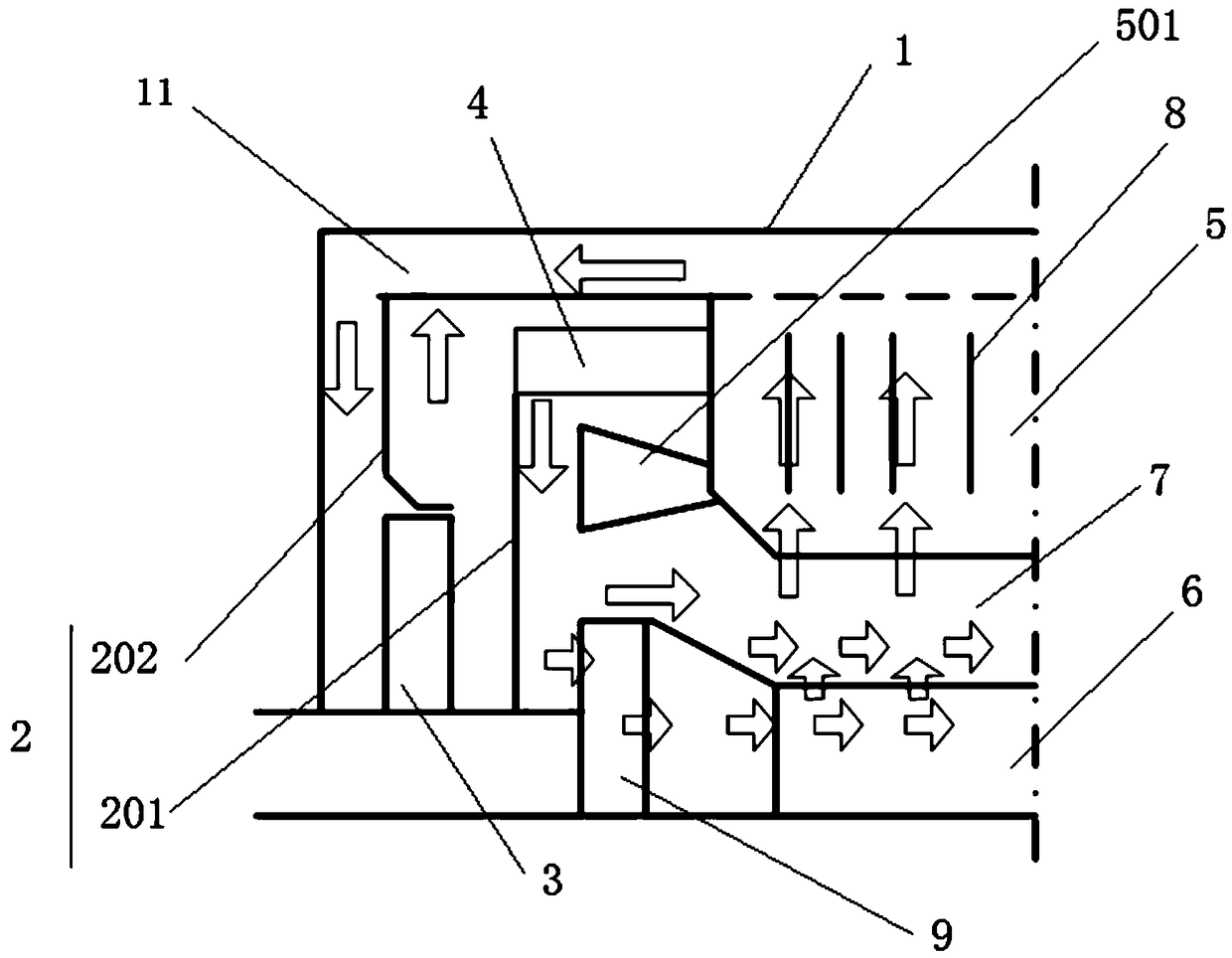

[0037] A large-scale synchronous condenser internal cooling and ventilation system with full air-cooling cooling mode of the present invention includes: an outer shell 1, and the outer shell 1 is provided with a first air duct 2, a cooling fan 3, and a water-air cooler 4 , stator 5 and rotor 6;

[0038] The first air channel 2 is arranged between the cooling fan 3 and the water-air cooler 4, and is used to introduce the wind in the cooling fan 3 into the water-air cooler 4, wherein the cooling fan 3 is arranged at the stator end The outside of the internal coil 501; the water-air cooler 4 is located between the cooling fan 3 and the stator 5;

[0039] Such as Figure 1-3 As shown, in a specific implementation of the embodiment of the present invention: the first air duct 2 includes a first baffle 201 and a second baffle 202; the first baffle 201 is arranged between the cooling fan 3 and the stator 5, used to separate the cooling fan 3 and the stator 5, one end of which is co...

Embodiment 2

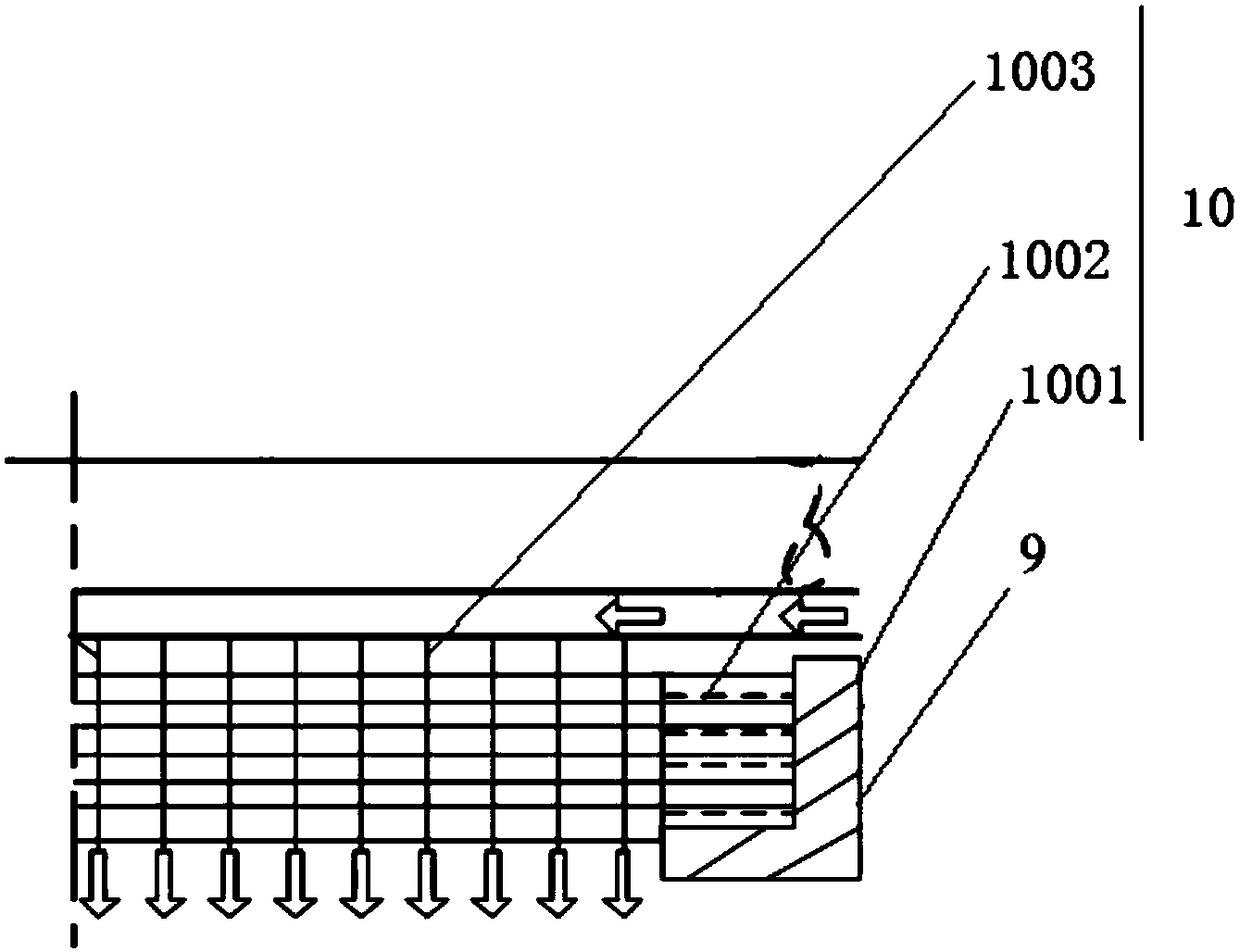

[0051] Based on Example 1, such as Figure 4 As shown, in this embodiment, an air supply hole 12 is provided at the end winding of the rotor, and the air supply hole 12 communicates with the second air duct 10 .

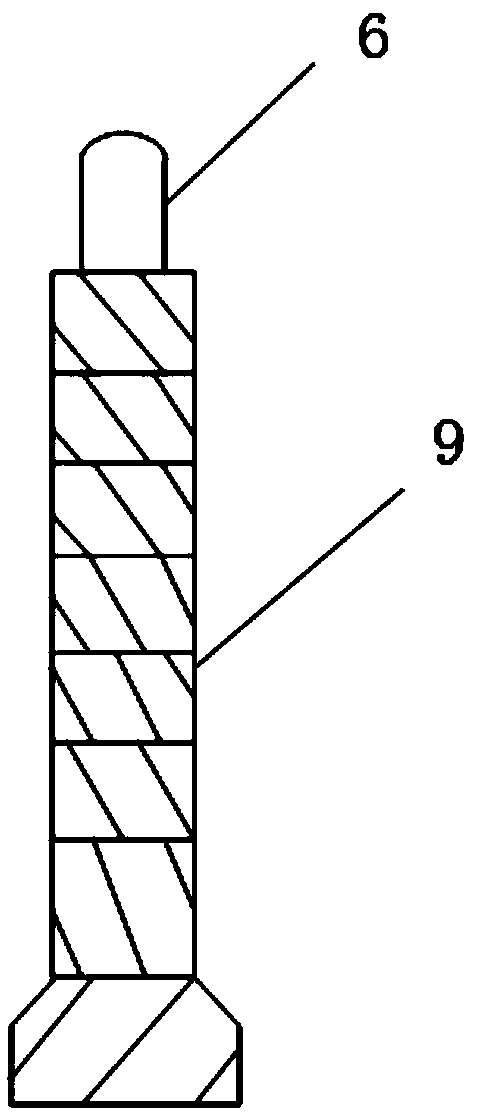

[0052] Further, the end windings of the rotor 6 are designed with wide copper rows and double rows of holes. For details, see image 3 . The rotor winding adopts fine-drawn silver-containing copper wire to improve creep resistance.

[0053] All the other parts are the same as in Example 1.

Embodiment 3

[0055] Based on Embodiment 1 or 2, the number of the first air passage 2, the cooling fan 3, and the water-air cooler 4 are two, and they are arranged symmetrically outside the two ends of the rotor.

[0056] All the other parts are identical with embodiment 1 or embodiment 2.

[0057] In summary:

[0058] In the present invention, the circulating ventilation generated by the cooling fan first enters the water-air cooler for cooling, and then the cooled circulating ventilation is divided into two paths to cool the rotor and the stator respectively, which solves the problem of water-air cooling in the traditional cooling method. When the cold air from the cooler passes through the cooling fan, heat is generated due to factors such as turbulence, eddy current, and friction, which cause the actual ventilation to have a certain temperature difference before and after passing through the cooling fan, so that the ventilation itself that cools the heat-generating parts already has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com