Glass product transfer mechanism with self-adjusting function

A glass product, self-adjusting technology, used in conveyor objects, transportation and packaging, lighting and heating equipment, etc., can solve problems such as occupying floor space, glass plate damage, economic loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

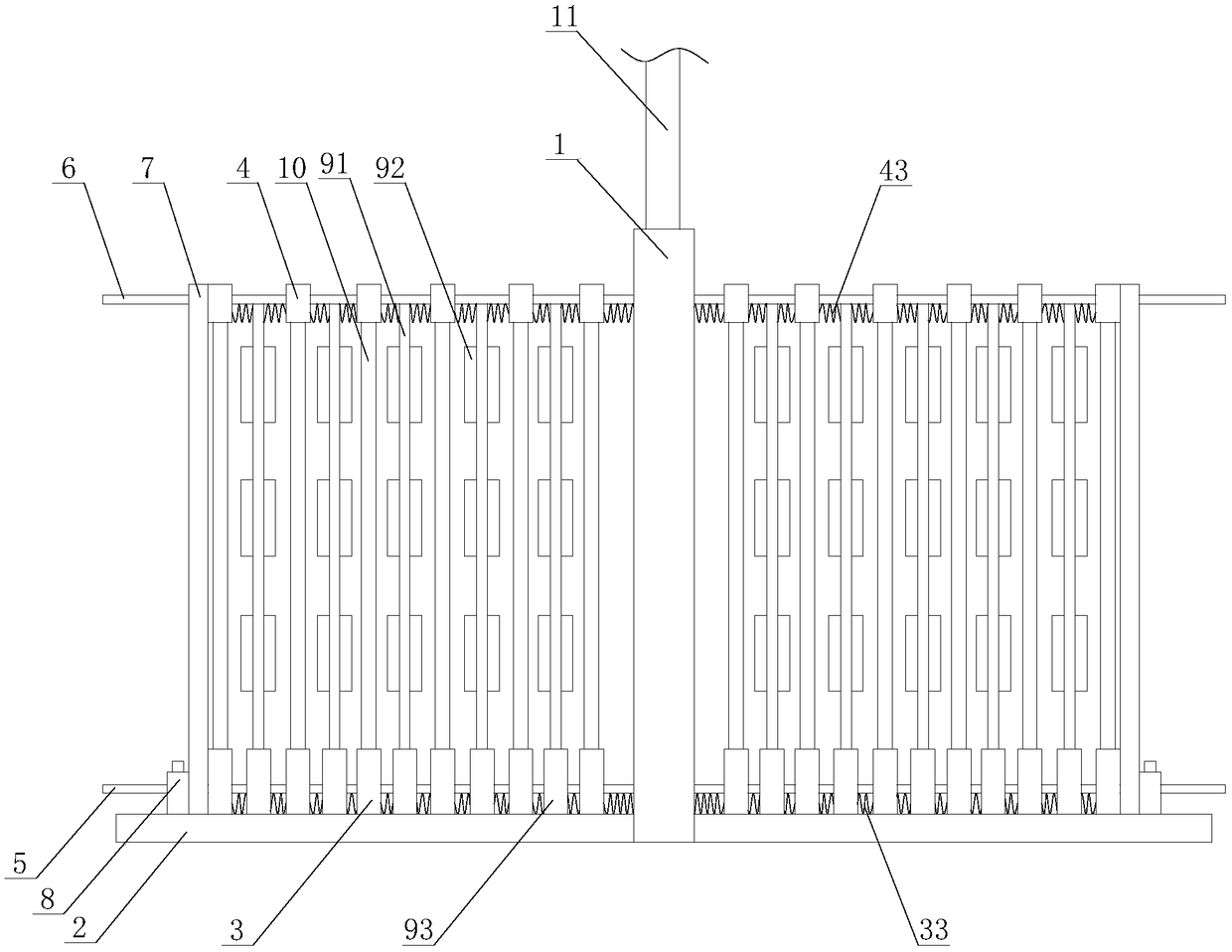

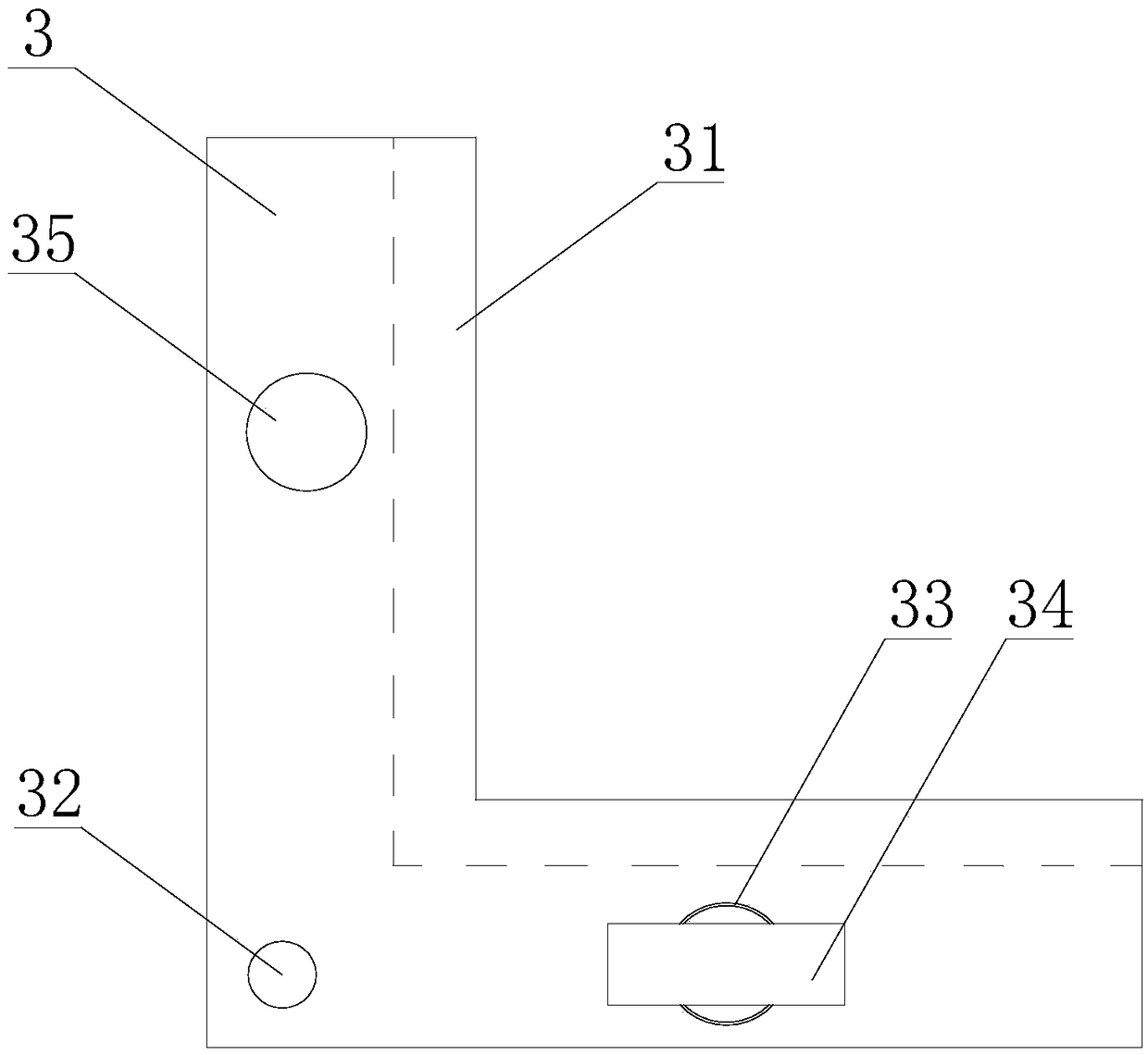

[0041] Such as Figure 1 to Figure 4The shown glass product transfer mechanism with self-adjusting function includes a suspension plate 1, a connecting rod 11 is fixedly connected to the top of the suspension plate 1, and two placing platforms 2 are fixed on the bottom of the suspension plate 1, and the two The placement table 2 is symmetrical about the suspension board 1; two bottom guide rods 5 and a top guide rod 6 fixed on the side of the suspension board 1 are arranged above the placement table 2, and the bottom guide rod 5 is sleeved with a bottom Fixing piece 3, described top guide rod 6 is sleeved with top fixing piece 4, and described top fixing piece 4 and two bottom fixing pieces 3 that are positioned at different bottom guiding rods 5 constitute the position-limiting mechanism jointly, and described position-limiting The mechanism is used to fix the glass plate 10; it also includes a limit pin 8, the limit pin 8 is matched with the limit pin hole provided on the pl...

Embodiment 2

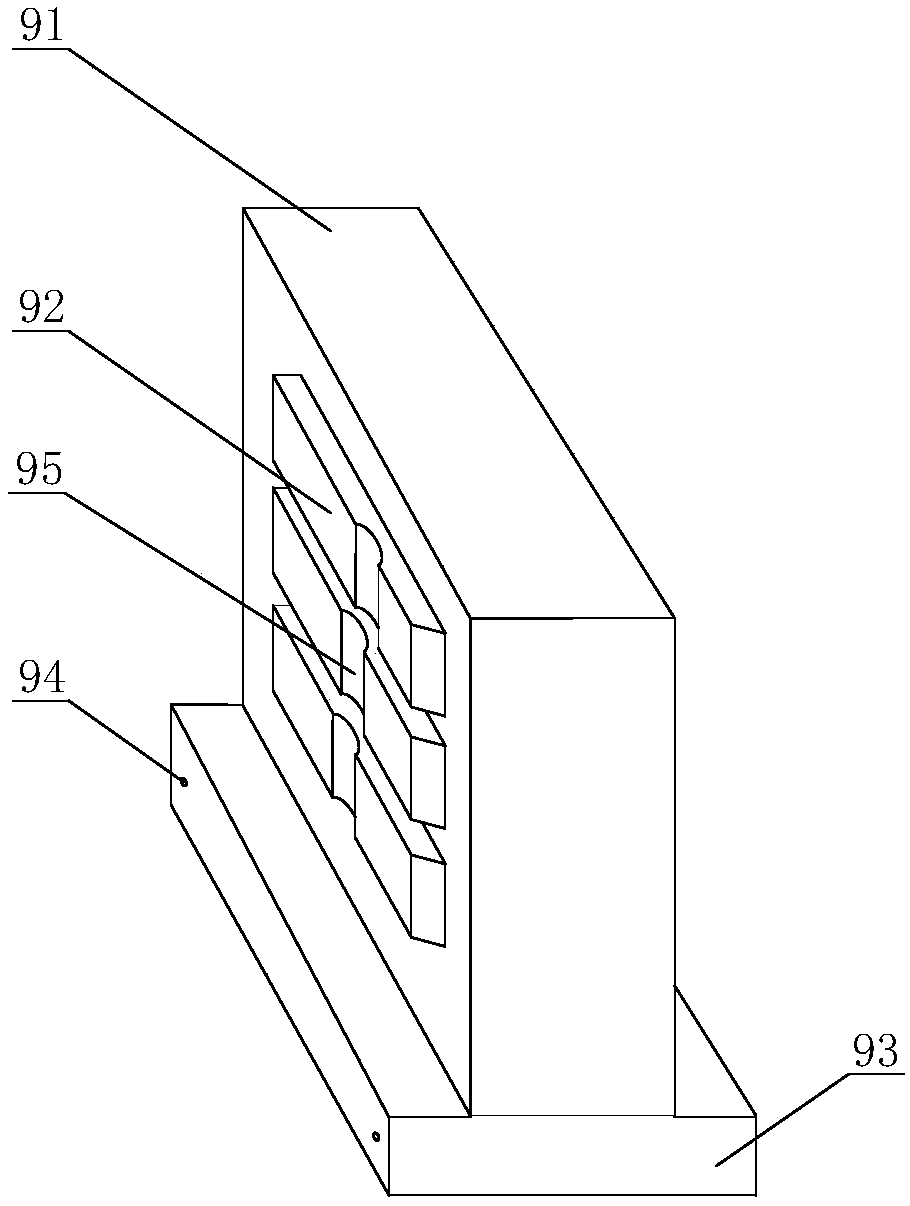

[0052] Such as figure 2 As shown, on the basis of Embodiment 1, the spoiler vane 92 of the present embodiment is provided with a spoiler groove 95, and the spoiler groove 95 is a semi-cylindrical body; the number of spoiler vanes 92 in the cleaning area There are three, and the three spoiler vanes 92 are distributed from top to bottom. The above-mentioned design prevents the glass plate 10 from being damaged by the impact force of the water flow on the glass plate 10, and the cleaning effect is very good. At the same time, the slope reduces the resistance of water flow into the cleaning area and reduces the load on the running system of the suspended transport vehicle.

Embodiment 3

[0054] On the basis of Embodiment 1 and Embodiment 2, in this embodiment, the positions of the top guide rod 6 and the two bottom guide rods 5 form an isosceles triangle. The above-mentioned design makes the clamping of the glass plate 10 more stable by the position-limiting mechanism formed by the bottom fixture 3 and the top fixture 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com