Fertilizer-plant washing coal gas circulating water purification device and method

A purification device and technology for circulating water, applied in chemical instruments and methods, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve problems such as increased operating costs, pump wear, environmental pollution, etc., to save operating costs, The effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

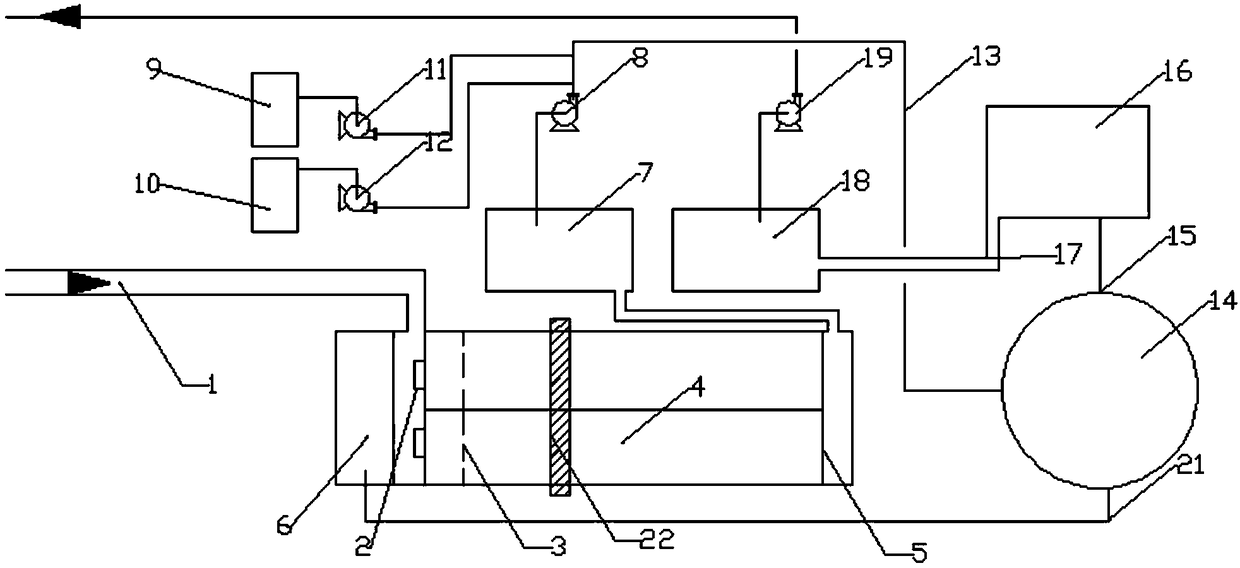

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0017] The invention discloses a purification device for washing gas circulating water in a chemical fertilizer plant, such as figure 1 As shown, it includes a return channel 1 connected to the outlet of the gas scrubber, and the return channel 1 is connected to the water inlet of the advection sedimentation tank 4 . The advection sedimentation tank 4 is used to settle the large particles of impurities in the circulating water by gravity and reducing the flow rate, so as to perform primary purification of the circulating water and avoid direct use of flocculation and sedimentation agents, resulting in waste of agents. In the advection sedimentation tank 4, large particles of impurities in the circulating water are deposited to the bottom of the tank by enlarging the flow cross section and reducing the flow velocity.

[0018] The number of ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com