Preparation method of composite metal organic framework material UiO-67

A technology of organic frameworks and composite metals, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of concentration quenching, small energy gap non-radiative recombination, incomplete energy transfer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

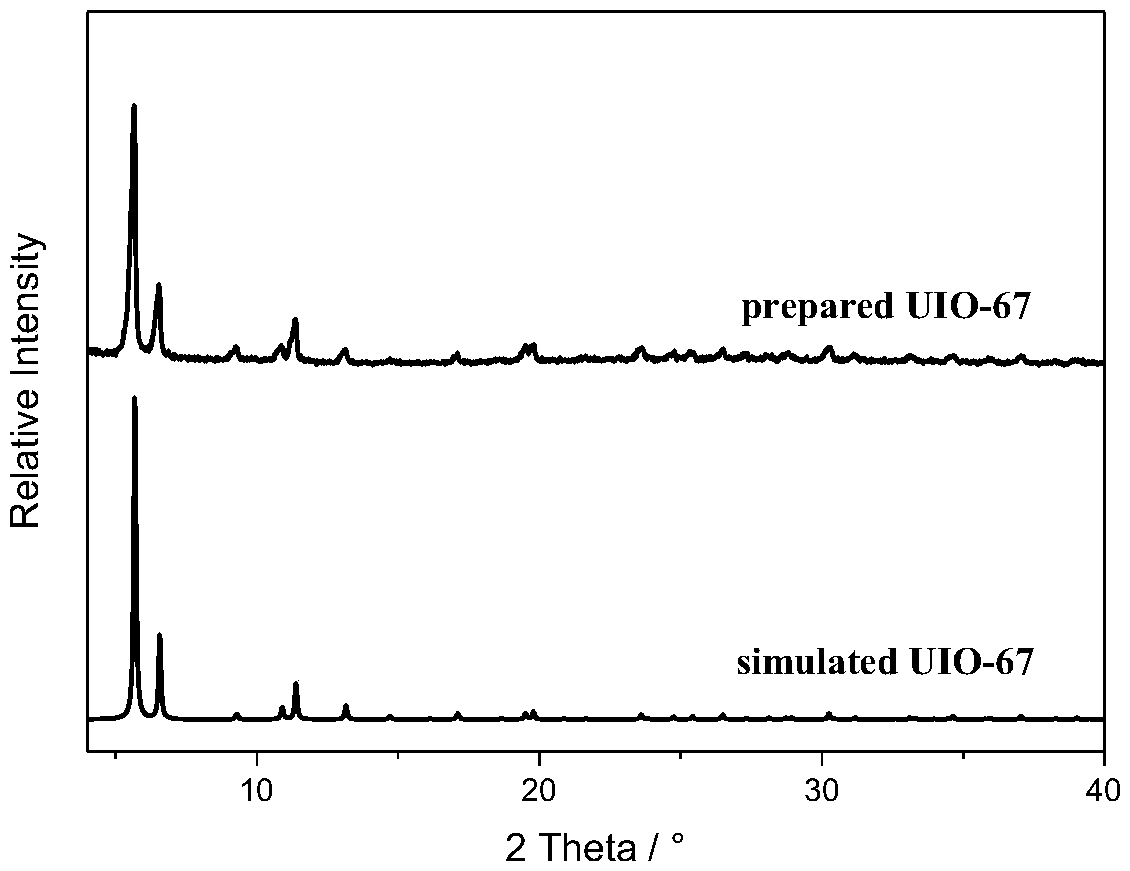

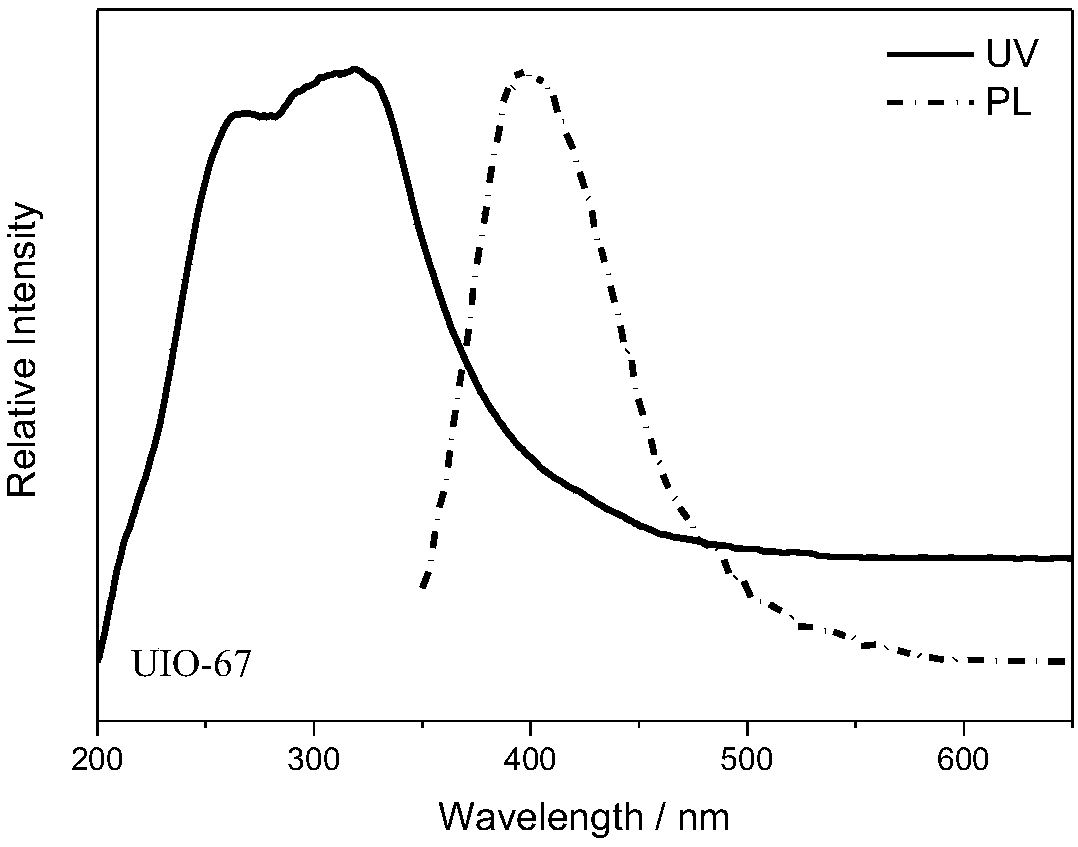

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

[0026] A preparation method of composite metal organic framework material UiO-67, comprising the steps of:

[0027] S1: 0.2517g ZrCl 4 (0.27mmol) was ultrasonically dispersed into 5mL of DMF, and 0.5mL of hydrochloric acid (36%-38%) was added during the ultrasonic dispersion to obtain a mixed solution A;

[0028] S2: Disperse 0.3682g of 4,4-biphenyldicarboxylic acid (BPDA) (0.38mmol) into 15mL of DMF (this operation was performed in a water bath at 80°C) with magnetic stirring to obtain a mixed solution B.

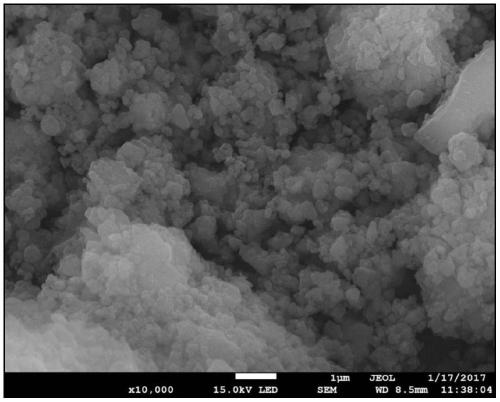

[0029] S3: Then the mixture A and B were blended into a polytetrafluoroethylene-lined reactor, then placed in an oven at 80°C for 24 hours, and then naturally cooled to obtain a white precipitate.

[0030] S4: Then wash with DMF and ETOH, respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com