A Process for Promoting Metal Foaming Evenly Using Sinking Balls to Absorb Heat

A metal foaming and metal technology, which is applied in the field of metal foaming, can solve the problems of rapid withdrawal without cooling substances, and achieve the effects of controlling the rework rate of products, prolonging the foaming time, and controlling the rework rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] see Figure 1-4 ;

[0030] A process for promoting uniform foaming of metals by using sinking balls to absorb heat, the steps are as follows:

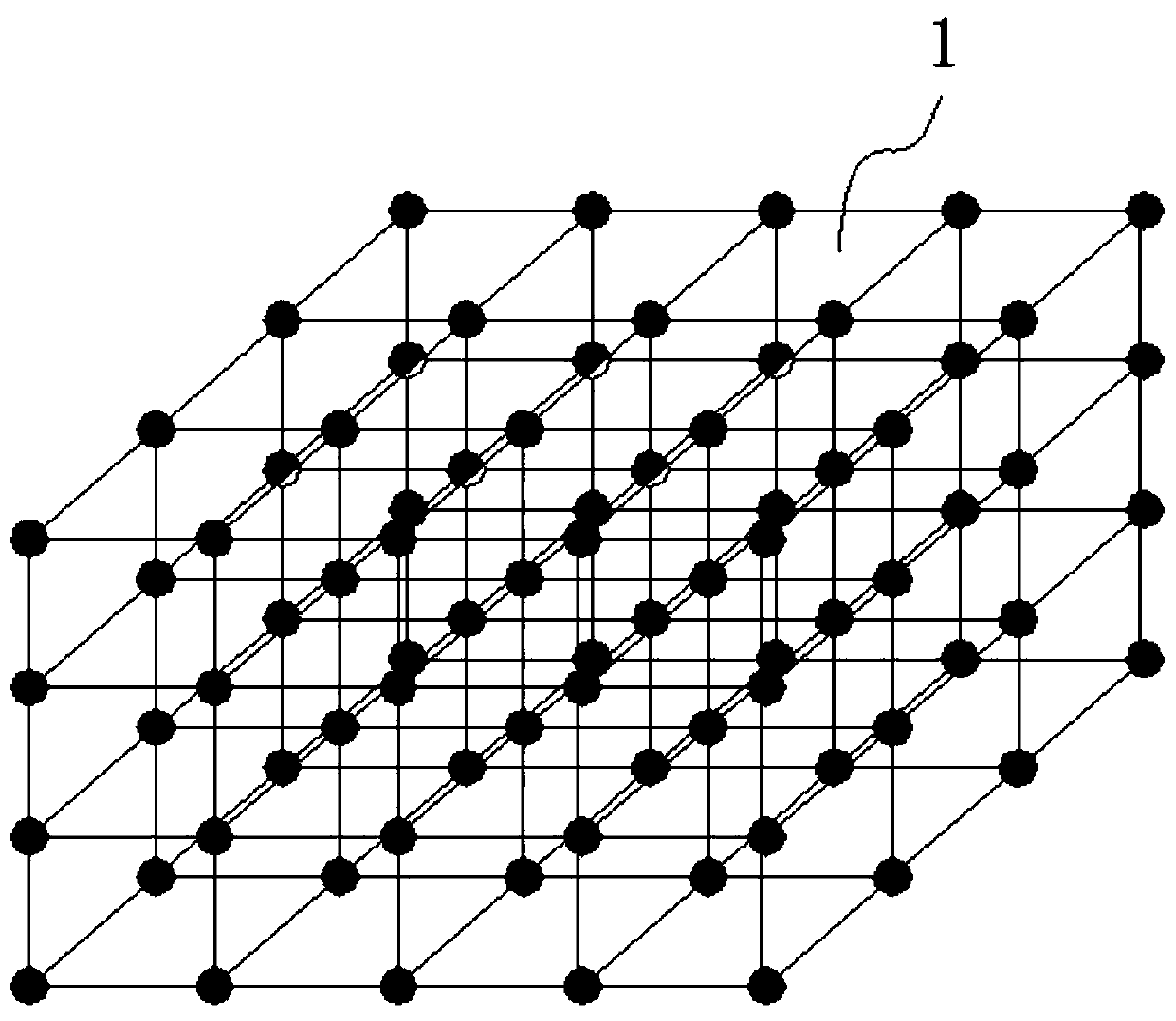

[0031] (1) According to the size of the metal foaming melt, the required metal balls such as steel balls are processed into a low-temperature metal ball array 1 of a three-dimensional space structure for use; the volume of the low-temperature metal ball array 1 is designed according to the volume of the foaming mold, which can Easy to put into the foaming mold;

[0032] (2) Cool the whole body of the low-temperature metal ball array 1 prepared in step (1) to a set low temperature for use (the temperature should be calculated and determined according to the total amount of foamed melt, the temperature, the quality of the metal balls and the amount of heat to be absorbed );

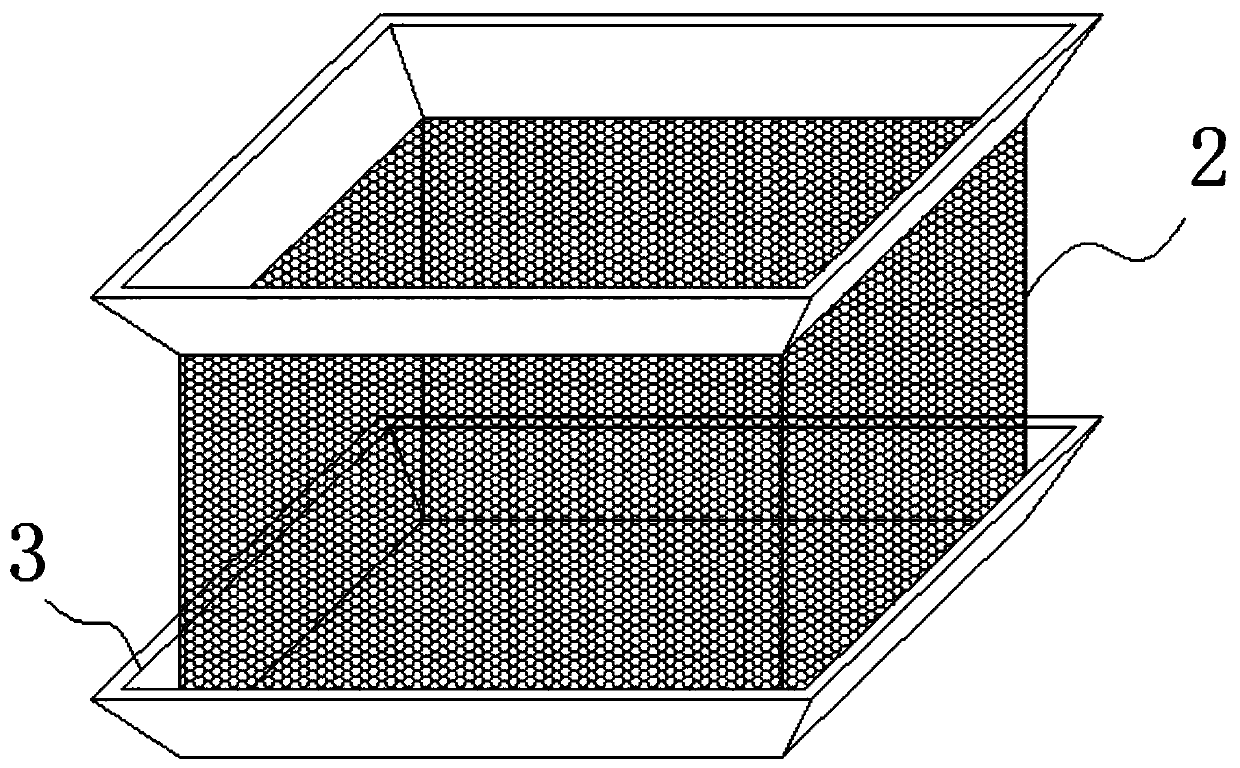

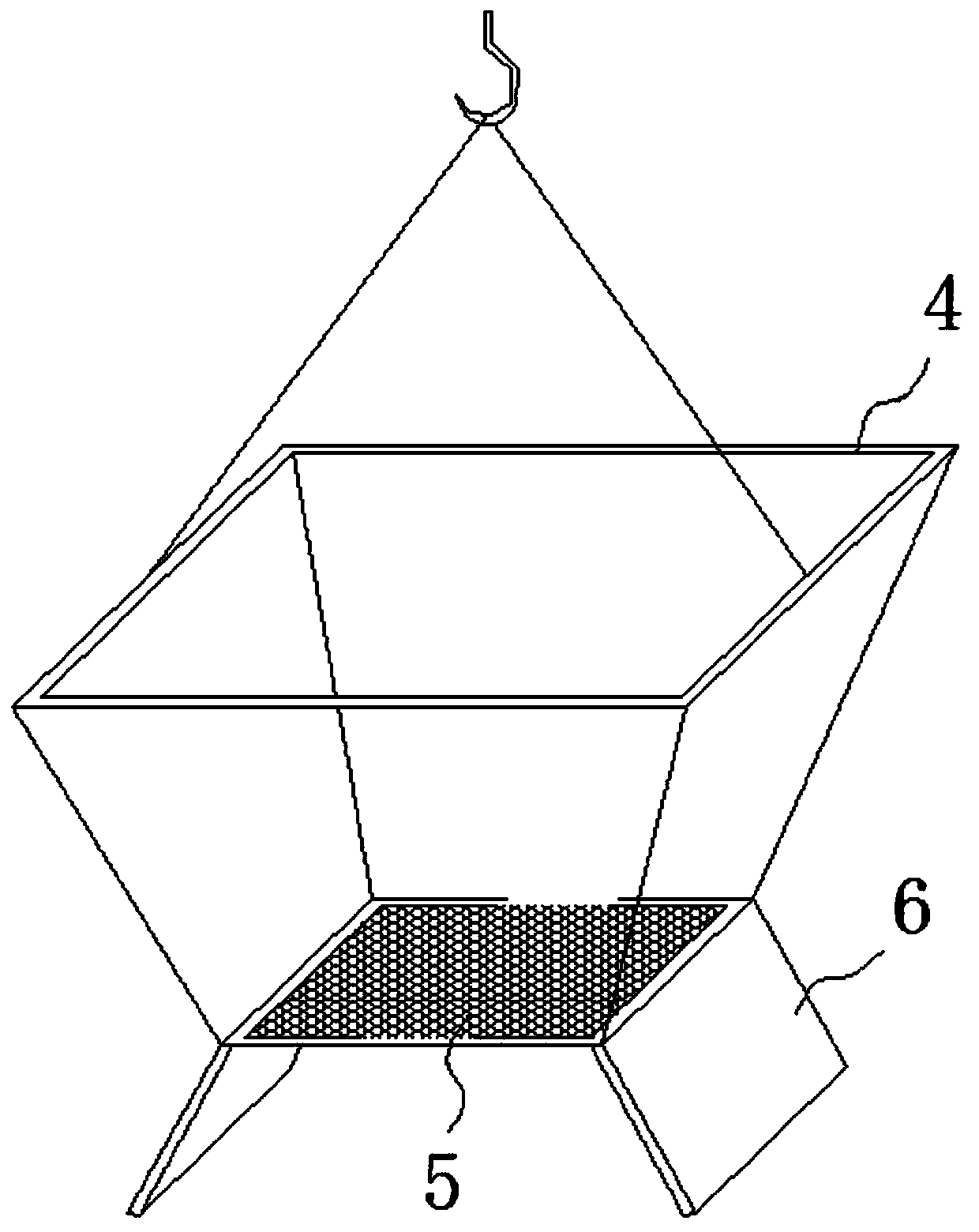

[0033] (3) Prepare the cooling pool 2 synchronously. The length, width, and height of the cooling pool 2 are respectively about 1.5 times the length, widt...

Embodiment 2

[0040] see Figure 1-4 ;

[0041] A process for promoting the uniform foaming of metal by using sinking balls to absorb heat, the steps are as follows:

[0042] (1) According to the size of the metal foaming melt, the required metal balls such as steel balls are processed into a low-temperature metal ball array 1 of a three-dimensional space structure for use; the volume of the low-temperature metal ball array 1 is designed according to the volume of the foaming mold, which can Easy to put into the foaming mold;

[0043] (2) Cool the whole body of the low-temperature metal ball array 1 prepared in step (1) to a set low temperature for use. The specific method is to put the low-temperature metal ball 1 with a three-dimensional space structure into a freezing device for freezing, and the temperature is lower than -20 ℃, the freezing time is greater than 1 hour;

[0044] (3) Synchronously prepare the cooling pool 2. The length, width, and height of the cooling pool 2 are about...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com