A construction method and equipment for asphalt concrete pavement of municipal roads

A technology of asphalt concrete and construction method, applied in roads, roads, road repair and other directions, can solve problems such as shortening the service life of pavement, and achieve the effect of reducing difficulty, ensuring durability and continuity, and reducing the degree of loosening and deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

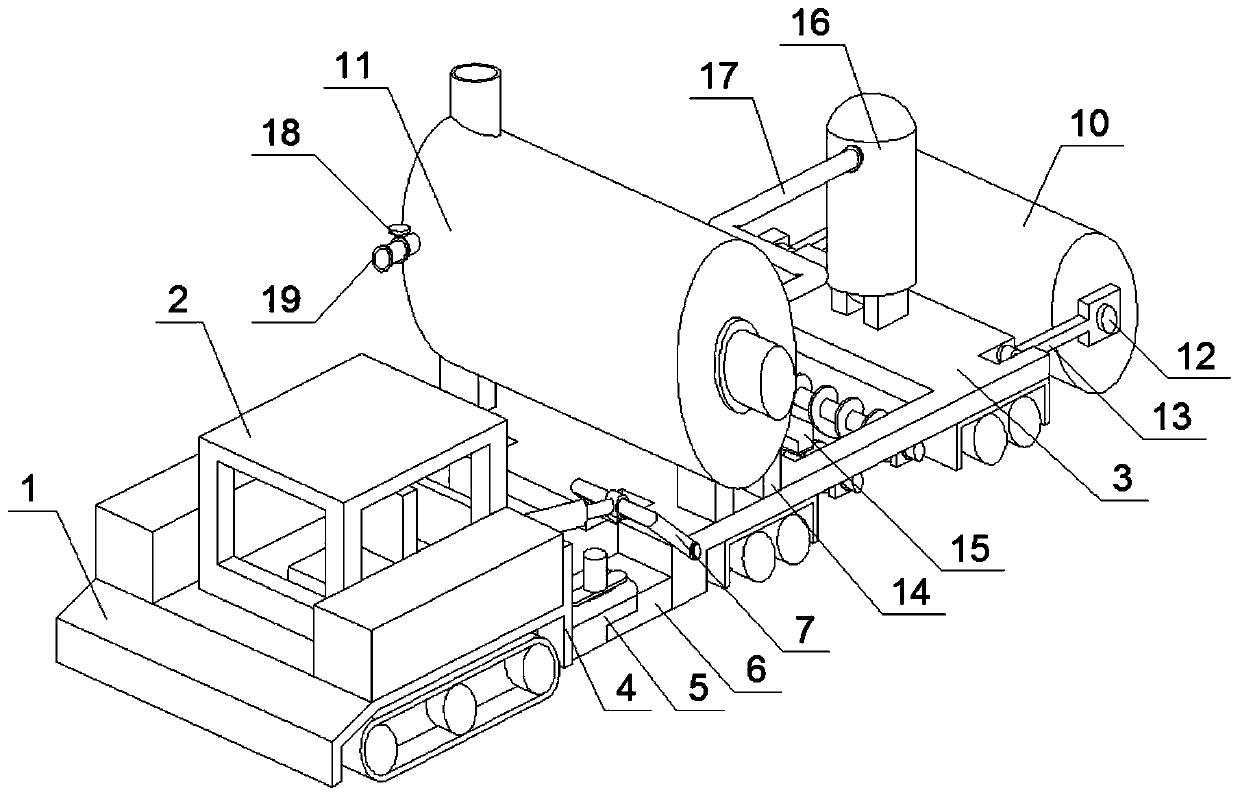

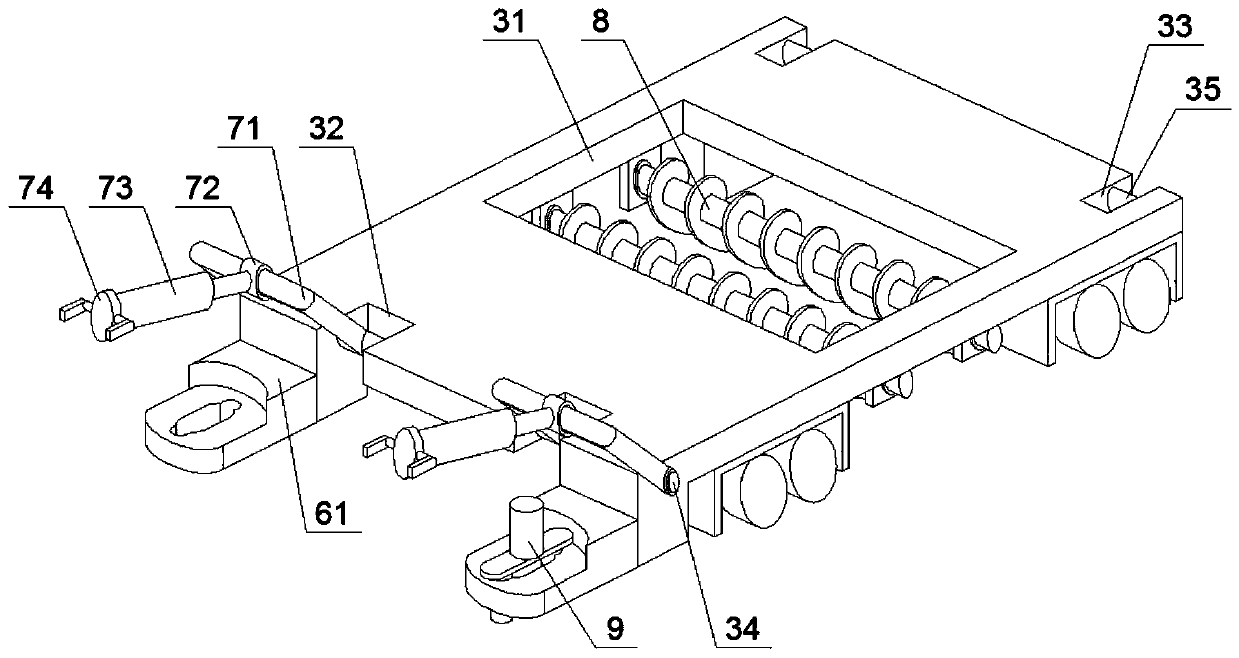

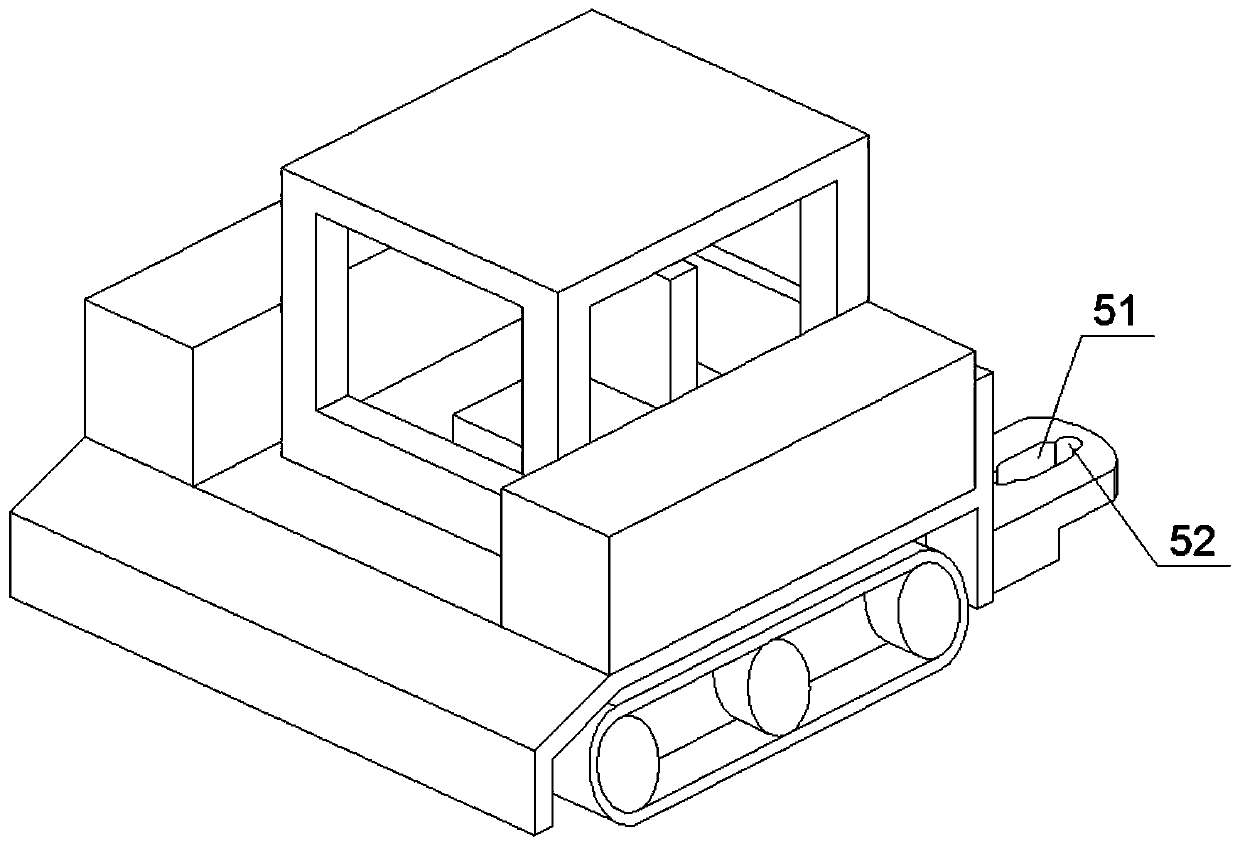

Image

Examples

Embodiment 1

[0023] The municipal road asphalt concrete pavement construction method provided in this embodiment includes: laying a concrete bearing layer on the subgrade surface, stirring and mixing coarse aggregate, fine aggregate and mineral powder according to the mass ratio of 5:45:71, stirring There is no limit to the location. After mixing evenly, the mixture is obtained. The mixture is transported to the laying site, and the mixture and asphalt are added to the mobile mixing equipment on site. The mass ratio of mixture to asphalt is 1:6, and the mixing temperature is controlled. The temperature is 180°C, and the mixing time is 5 minutes. After the mixture and asphalt are mixed evenly, the asphalt binder is obtained, and the asphalt binder is spread on the concrete bearing surface. Due to the short discharge time, the discharge temperature of the asphalt binder is 130 At about ℃, at least two filling and leveling procedures are carried out on the spread asphalt mixture, so that it is...

Embodiment 2

[0025] The municipal road asphalt concrete pavement construction method provided in this embodiment includes: laying a concrete bearing layer on the subgrade surface, stirring and mixing coarse aggregate, fine aggregate and mineral powder according to the mass ratio of 10:52:82, stirring There are no restrictions on the location. After mixing evenly, the mixture is obtained. The mixture is transported to the laying site, and the mixture and asphalt are added to the mobile mixing equipment on site. The mass ratio of mixture to asphalt is 1:15, and the mixing temperature is controlled. The temperature is 150°C, and the mixing time is 20 minutes. After the mixture and asphalt are mixed evenly, the asphalt binder is obtained, and the asphalt binder is spread on the concrete bearing surface. Due to the short discharge time, the discharge temperature of the asphalt binder is 120 At about ℃, at least two filling and leveling procedures are carried out on the spread asphalt mixture, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com