Efficient ore crushing technology and crushing system thereof

A high-efficiency ore crushing technology, which is applied in the field of efficient ore crushing technology and its crushing system, can solve the problems of poor crushing effect of the crushing system, low crushing efficiency of the primary crushing device, and uneven particle size of the ore, so as to achieve reasonable process design, Easy post-processing, good crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

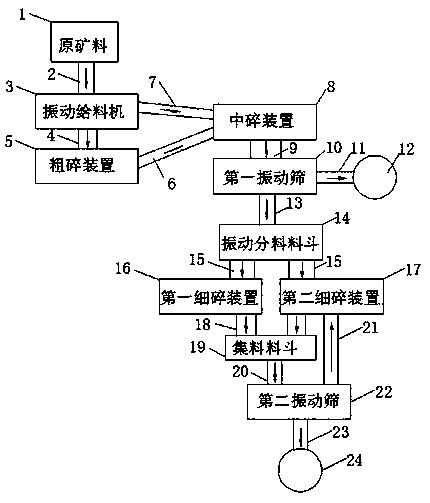

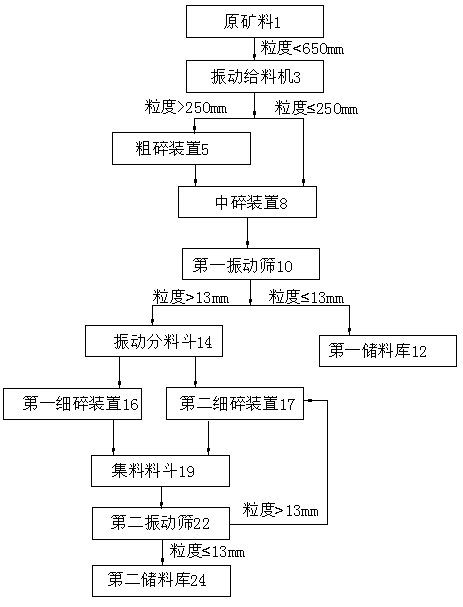

[0042] see figure 1 , this embodiment provides an efficient ore crushing system, including a coarse crushing device 5, a medium crushing device 8, a first fine crushing device 16, a second fine crushing device 17, a first vibrating screen 10, and a second vibrating screen 22; The coarse crushing device 5 is provided with a vibrating feeder 3, and the raw material ore 1 enters the vibrating feeder 3 through the first conveyor belt 2; the particle size of the raw material ore is less than 650 mm; the vibrating feeder 2 is provided with two discharge ports, and the ore particle size is The discharge port larger than 250mm is connected to the feed port of the primary crushing device 5 through the first blanking channel 4, and the discharge port with ore particle size less than or equal to 250mm is connected to the feed port of the secondary crushing device 8 through the third conveyor belt 7. 5. The discharge port is connected to the feed port of the secondary crushing device 8 th...

Embodiment 2

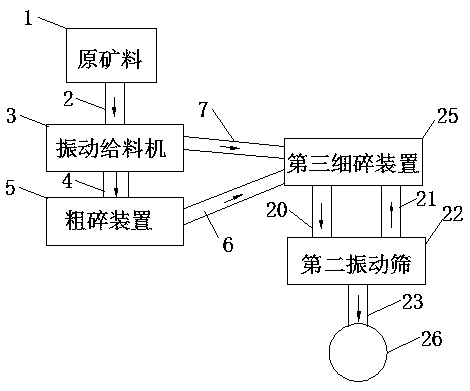

[0063] In order to save the equipment cost, this embodiment can be adopted. On the basis of the first embodiment, the middle crushing treatment process is omitted, and the raw ore material is subjected to the fine crushing treatment after the coarse crushing treatment.

[0064] see image 3 , this embodiment provides an efficient ore crushing system, including a coarse crushing device 5, a third fine crushing device 25, and a second vibrating screen 22; the coarse crushing device 5 is provided with a vibrating feeder 3, and the raw ore 1 is The first conveyor belt 2 enters the vibrating feeder 3; the raw material ore particle size is less than 650mm; the vibrating feeder 2 is provided with two discharge ports, and the discharge port with the ore particle size larger than 200mm passes through the first blanking channel 4 and the coarse crushing device 5. The feed port is connected, the discharge port with ore particle size less than or equal to 200mm is connected with the feed ...

Embodiment 3

[0077] This embodiment is consistent with the crushing process and crushing system of the first embodiment. The primary crushing device 5 is a PE900*1200 jaw crusher; the secondary crushing device 8 is a SMG200S-M cone crusher; the first fine crushing device is a SMG200S-M cone crusher; Both the device 16 and the second fine crushing device 17 are SMG100-F cone crushers.

[0078]The process design of the invention is reasonable, the ore particle size is screened and then classified and crushed, the crushing efficiency is high, the crushing effect is good, the crushed particles are uniform, and the post-processing is convenient; the mechanical devices of the system are reasonably selected, stable in operation, easy to maintain, and can effectively improve Yield.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com