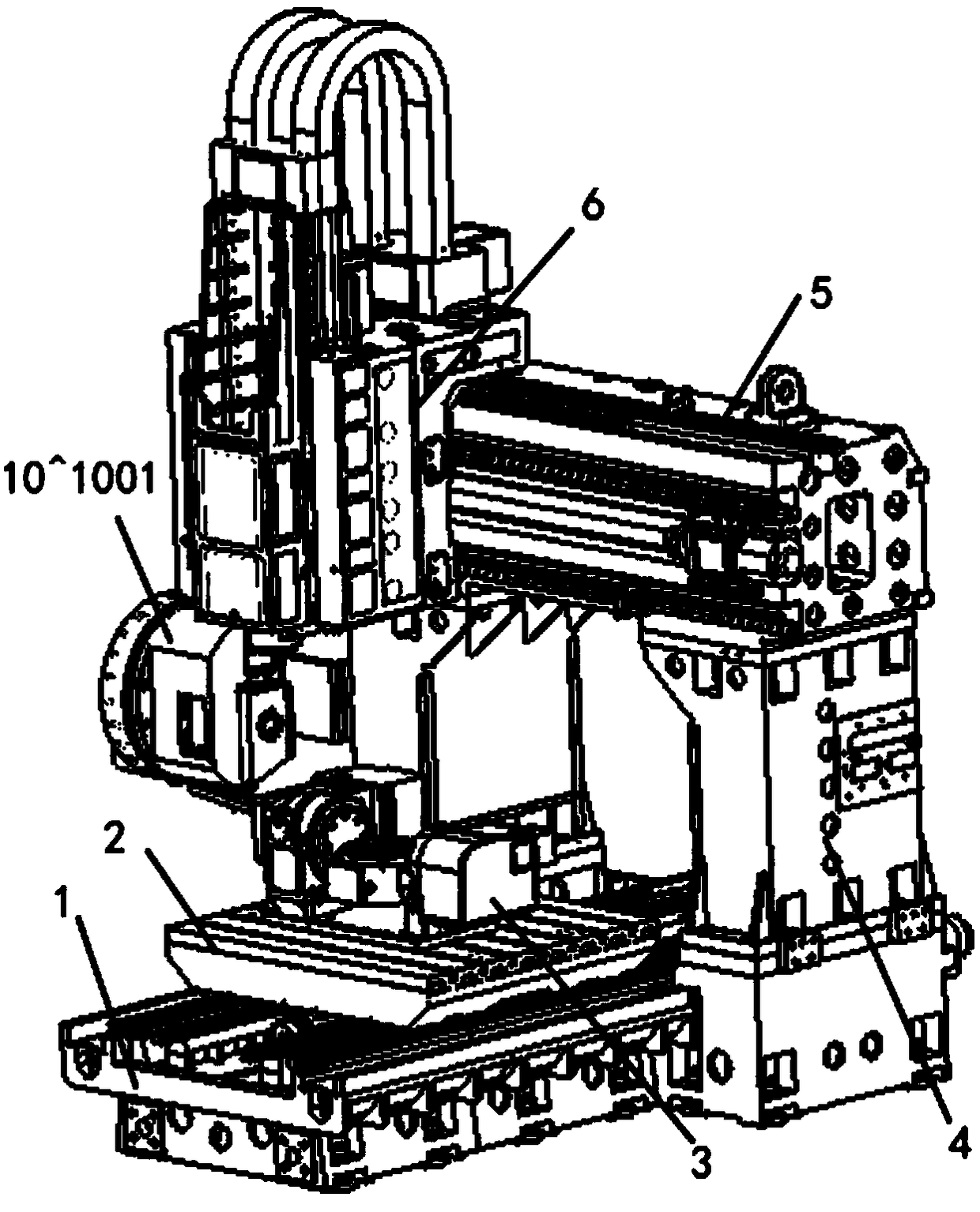

Intelligent composite type multi-axis numerical control machining center

A processing center and composite technology, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of wasting production resources, destroying the positioning foundation, etc., to reduce the waste of resources, ensure processing accuracy and processing efficiency ,Easy for quick tool change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

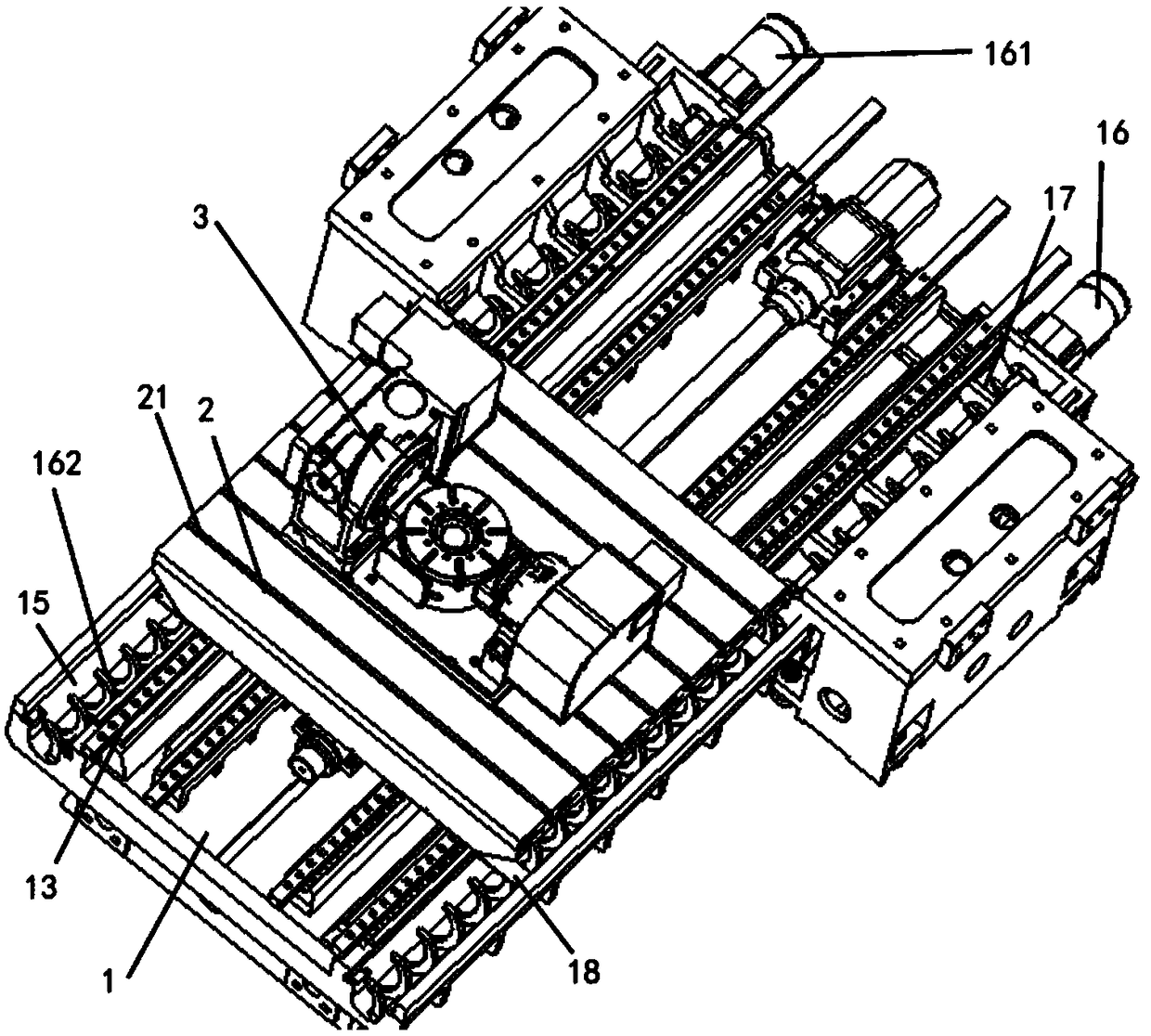

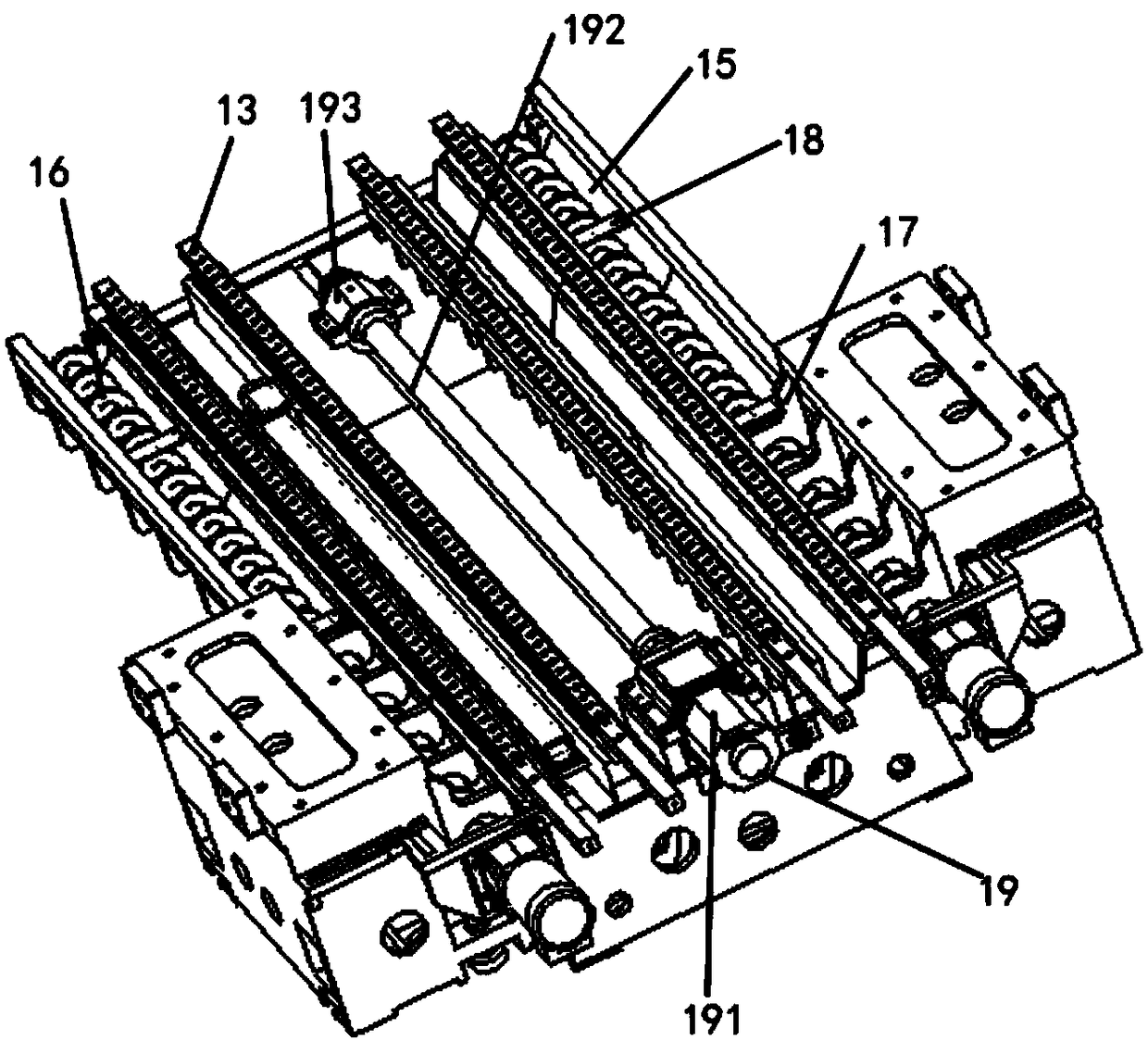

[0053] see Figure 1 to Figure 14 , this embodiment shows an intelligent compound multi-axis CNC machining center, including:

[0054] Base 1: including the base main body 11, a number of linear slide rail setting grooves 12 are uniformly arranged on the base main body 11, linear slide rail 13 is arranged in the linear slide rail setting groove 12, and the end of the linear slide rail setting groove 12 is provided with an embedded The slope 121 and the linear slide rail setting groove 12 are evenly provided with several embedded auxiliary fixed blocks 14, and the embedded auxiliary fixed block 14 is provided with a fixed slide-in slope 141 matching the embedded slope 121, through the embedded auxiliary fixed block 14 and The linear slide rails 13 are respectively provided with fixing parts, and through the mutual cooperation of the fixing parts and the embedded auxiliary fixing block 14, the high stability of the linear slide rails 13 is formed to ensure the stability of the m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap