Production method of density distribution controllable solid wood compression compacted board

A density distribution and board production technology, which is applied in the direction of wood processing appliances, wooden veneer joints, manufacturing tools, etc., can solve problems such as the release of harmful substances, and achieve the effect of increasing value, expanding the field of use, and improving quality and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

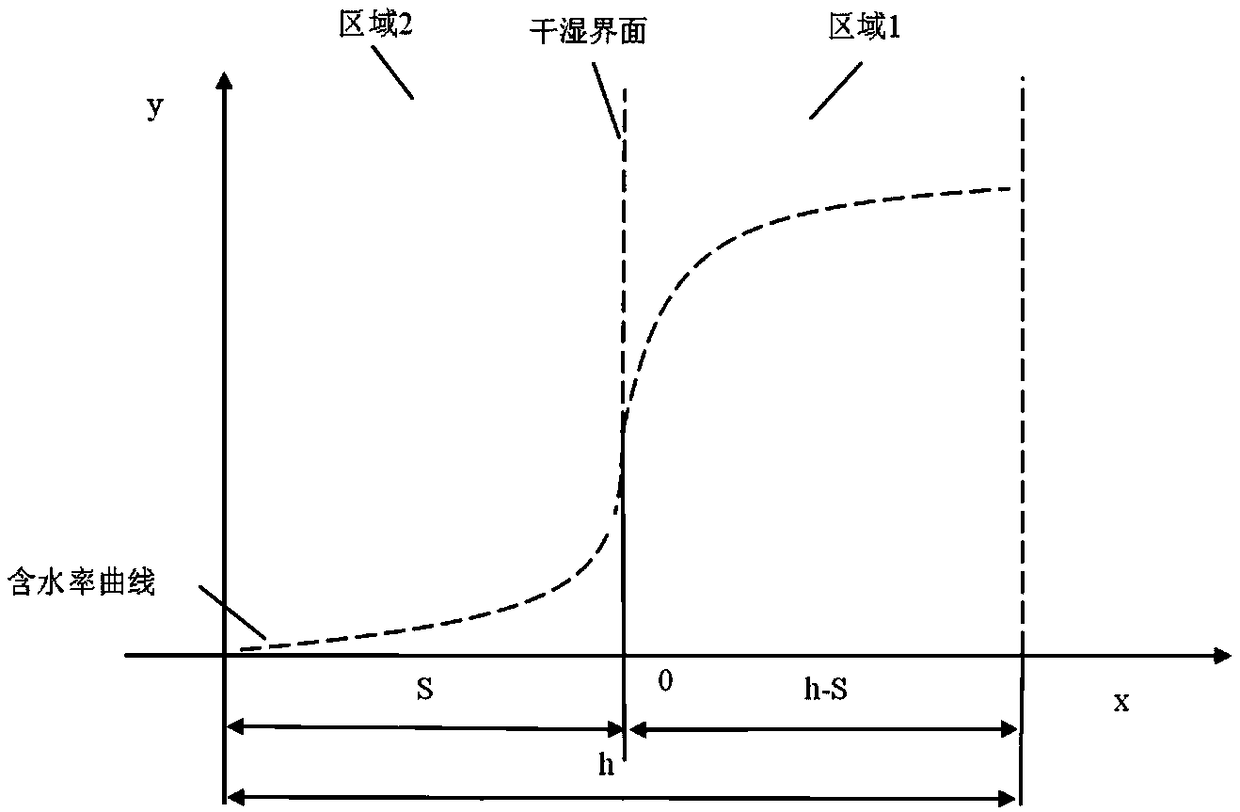

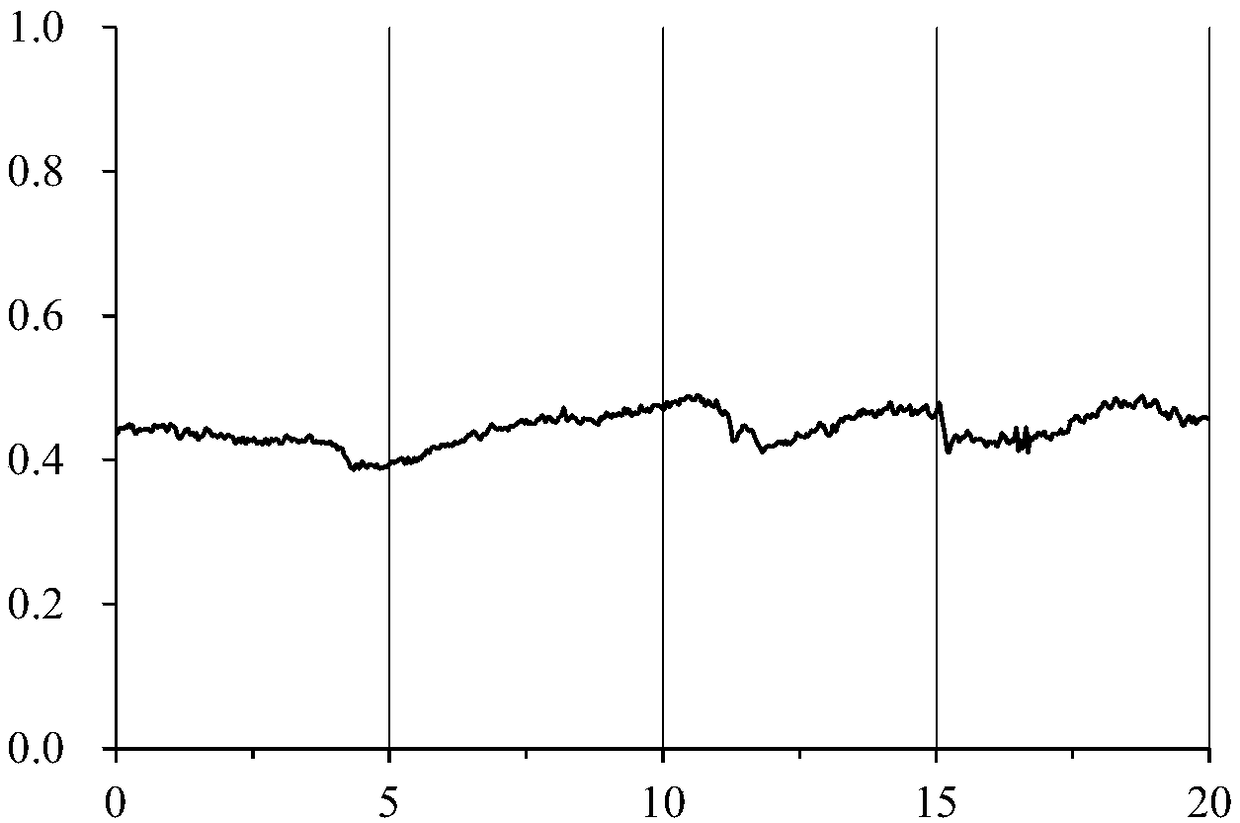

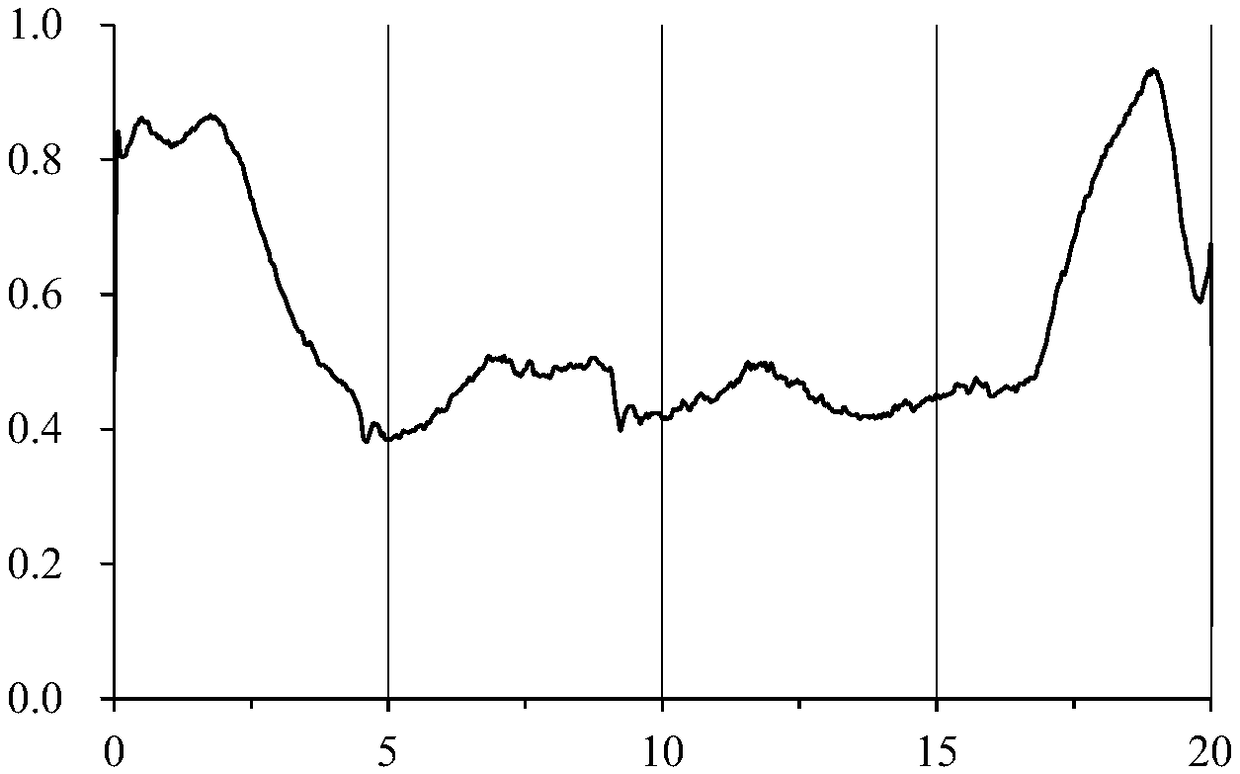

[0043] Embodiment 1: A method for producing solid wood compression and densification boards with controllable density distribution, adjusting the moisture content of each layer in the thickness direction of the solid wood boards by means of immersion and / or drying, and forming a dry layer in the inner thickness direction of the solid wood boards. The wet area is formed in the high moisture content layer in the thickness direction inside the solid wood board, and the dry-wet interface is formed at the junction of the dry area and the wet area, such as the attached figure 1 shown, with figure 1 It is a schematic diagram of adjusting the moisture content of a solid wood board to form a dry area and a wet area. The abscissa x is the position in the thickness direction of the board, and the ordinate is the moisture content corresponding to the abscissa position. In the figure, area 1 is the dry area, area 2 is the wet area, and the interface between area 1 and area 2 is the dry-wet...

Embodiment 2

[0052] Embodiment 2: The specific manufacturing method of surface layer compression and densification plate:

[0053] Single surface (only one surface) compression process:

[0054] After immersing the sheet with a moisture content below the air-dried moisture content value (below 10%), or floating or wet on the water surface, make the surface moisture content greater than 20%, and then place it on a single-sided pressing plate and heat it to 100-150°C. On the upper part of the press, the water-soaked surface should be on the same side as the heating plate, and continuously compressed at a speed of 2-7mm / min, with a pressure of more than 3MPa, until the compression reaches the target thickness, forming a single-sided compressed wood soaked in water and compressed on the heating surface;

[0055] Upper and lower surface compression process:

[0056] Air-dry wood to absolute dry wood with an initial moisture content of less than 15%: soak in water after sealing or spray water w...

Embodiment 3

[0058] Embodiment 3: The specific manufacturing method of the intermediate layer compression and densification plate:

[0059] After the end (cross section) of the board with a moisture content greater than 15% is coated with materials such as bone glue, paraffin, asphalt, etc. for wood end sealing, it is carried out at a temperature above 100°C by means of contact (hot pressing plate) heat conduction. The clamping and drying treatment for more than 60s moves the dry-wet interface of the board to the predetermined position, and makes the yield stress difference between the dry area and the wet area of the board 0.25MPa, and uses the displacement sensor to control the final compression amount, and then uses 100~ 150°C hot press compression, continuous compression at a speed of 2-7mm / min, and a pressure of 3MPa or more, can form a compressed and densified middle layer of compressed and densified wood with no compression on the surface and two compressed layers inside.

[0060]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com