A kind of polyolefin heat-shrinkable film and its preparation method and application

A polyolefin heat shrinkable film technology, applied in applications, other household appliances, chemical instruments and methods, etc., can solve problems such as difficulty in maintaining tensile properties, achieve good gloss, improve transparency and mechanical properties, and surface water resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

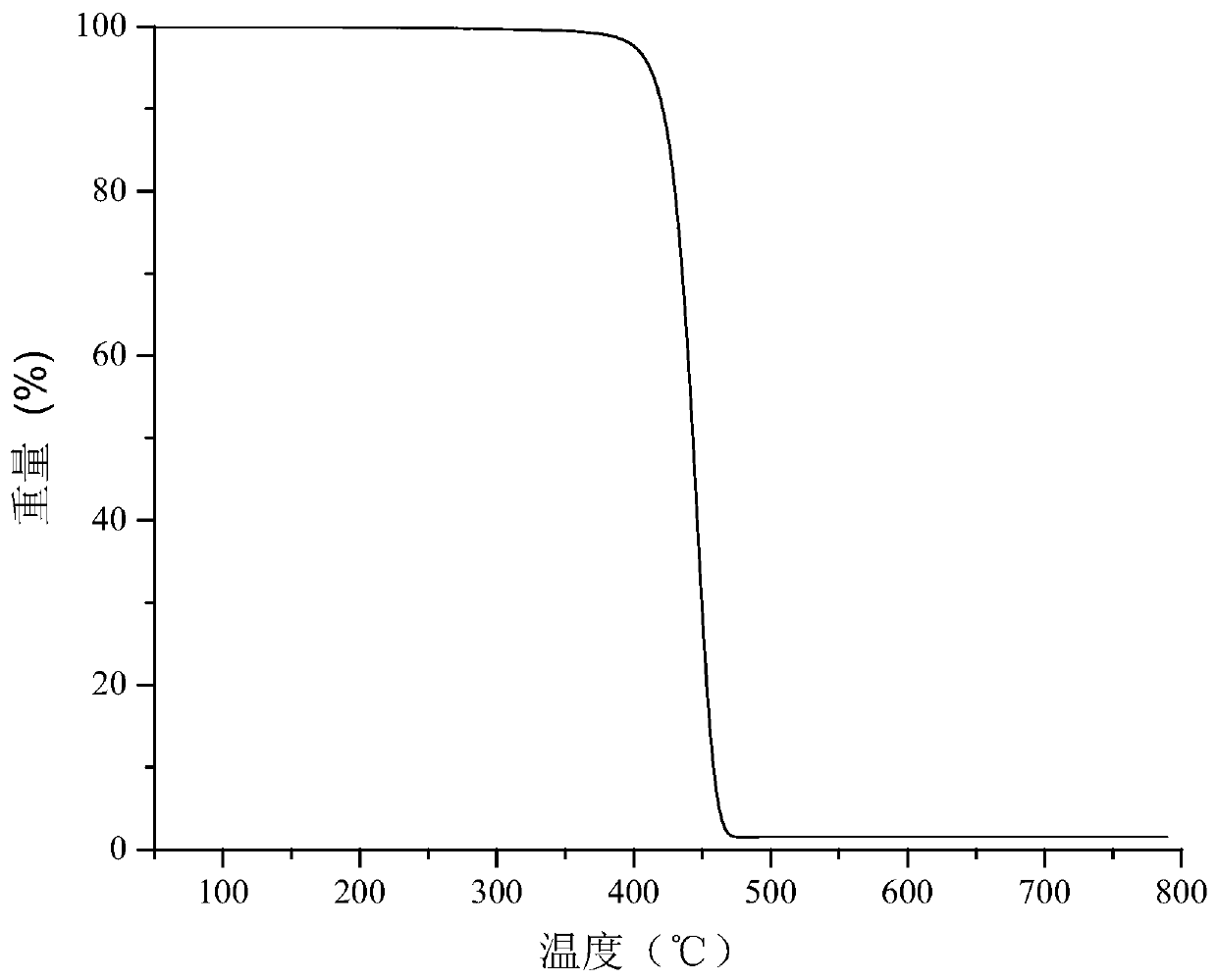

Image

Examples

Embodiment 1

[0071] The polyolefin heat-shrinkable film prepared in this example comprises a polypropylene outer layer, a polypropylene inner layer, and three layers of polyethylene middle layers, with a total of five-layer structure, wherein the raw material composition of the polypropylene outer layer and the polypropylene inner layer are exactly the same , are recorded as the PP layer, and the composition of the raw materials of the three-layer polyethylene middle layer is exactly the same, and are recorded as the PE layer. Specifically, the mixture of the PP layer and the PE layer is prepared according to the following formula:

[0072] PP layer:

[0073] 90 copies of imported polypropylene masterbatch (6612L);

[0074] Micron-level silicon dioxide (2μm), nano-level silicon dioxide (50nm), the mass ratio is 2:1, a total of 5 parts;

[0075] Polydimethylsiloxane-polyethylene block copolymer (number average molecular weight is 6400g / mol, PDI=1.5, siloxane content 21wt%) 3 parts, maleic ...

Embodiment 2

[0090] In the PP layer mixture, except for the compatibilizer, the composition and proportioning of other raw materials are exactly the same as in Example 1, the difference is that 3 parts of polydimethylsiloxane-polyethylene graft copolymer (number average molecular weight of 9800g / mol, PDI=2.3, siloxane content 38wt%) and 2 parts of maleic anhydride grafted polyethylene;

[0091] In the PE layer mixture, except for the compatibilizer, the composition and proportion of other raw materials are exactly the same as in Example 1, the difference is that only 2 parts of polydimethylsiloxane-polyethylene graft copolymer are added, and 2 parts of horse To acid anhydride grafted polyethylene;

[0092] The preparation process is exactly the same as that in Example 1, and the performance parameters of the polyolefin heat-shrinkable film prepared in this example are listed in Table 1 below.

Embodiment 3

[0094] In the PP layer mixture, except for the polypropylene masterbatch and compatibilizer, the composition and proportion of other raw materials are exactly the same as in Example 1, the difference is that the addition of polypropylene masterbatch is 78 parts, polydimethylsiloxane -The addition of polyethylene block copolymer is 10 parts, and the addition of maleic anhydride grafted polyethylene is 4 parts;

[0095] The preparation process is exactly the same as that in Example 1, and the performance parameters of the polyolefin heat-shrinkable film prepared in this example are listed in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com