Potassium fulvate urea and preparation method thereof

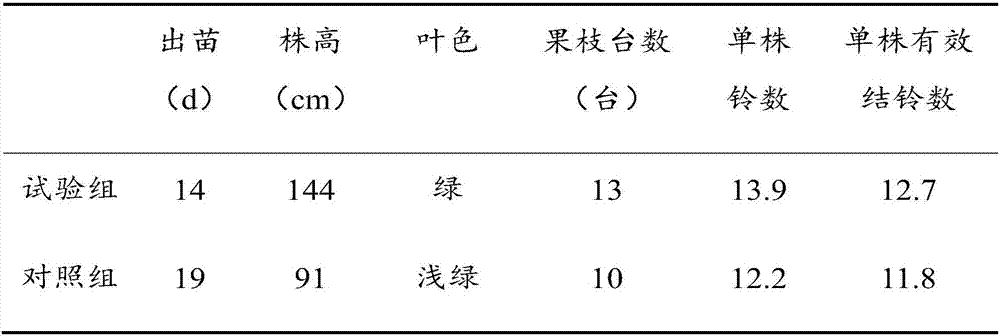

A technology of potassium fulvic acid and urea, applied in the field of potassium fulvic acid urea and its preparation, can solve the problems affecting the growth and development status and yield of cotton, poor ability of root system to absorb nutrients, etc., so as to improve the utilization rate of each element and promote absorption. The effect of using and improving soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] After first mixing 2 parts by weight of sodium alginate and 98 parts by weight of water, stir for the first time at a speed of 1300r / min, and stir for 45 minutes to form the first mixture; then mix 0.5 parts by weight of lanthanum, 0.3 parts by weight of yellow Potassium humate is added to the first mixture and stirred for the second time at a rotating speed of 1500r / min, and stirred for 45min to form the second mixture; after adding 200 parts by weight of urea (comprising 90wt% of urine), at a rotating speed of 1800r / min Stirring was carried out for the third time, and the third mixture was obtained by stirring for 45 min. The third mixture is transported to the urine pump, enters the evaporation system, evaporates excess water, and then vacuum granulates with a granulation tower at 130°C and normal pressure to obtain yellow granules with a water content of 0.4% and a diameter of 1.1 mm. Potassium humate urea.

Embodiment 2

[0033] First mix 11.3 parts by weight of sodium alginate and 188.7 parts by weight of water, then stir for the first time at a rotating speed of 1400r / min, and stir for 60 minutes to form the first mixture; then mix 1.2 parts by weight of cerium, 0.4 parts by weight of yellow Potassium humate is added to the first mixture and stirred for the second time at a rotating speed of 1800r / min, and stirred for 60min to form the second mixture; after adding 220 parts by weight of urea (including 95wt% urine), at a rotating speed of 2000r / min Stir for the third time and stir for 60 min to obtain the third mixture. The third mixture is sent to the urine pump, enters the evaporation system, evaporates excess water, and then uses a granulation tower to carry out vacuum granulation under 140°C and normal pressure conditions to obtain yellowish granules with a water content of 1% and a diameter of 3.2mm. Potassium humate urea.

Embodiment 3

[0035] After mixing 4 parts by weight of sodium alginate and 196 parts by weight of water, stir for the first time at a speed of 1350r / min, and stir for 55 minutes to form the first mixture; then mix 0.8 parts by weight of praseodymium, 0.3 parts by weight of yellow Potassium humate is added to the first mixture and stirred for the second time at a rotating speed of 1700r / min, and stirred for 55min to form the second mixture; after adding 210 parts by weight of urea (comprising 92wt% of urine), at a rotating speed of 1900r / min Stirring was carried out for the third time, and the third mixture was obtained by stirring for 55 min. The third mixture is sent to the urine pump, enters the evaporation system, evaporates excess water, and then uses a granulation tower to carry out vacuum granulation under 135°C and normal pressure conditions to obtain yellow granules with a water content of 0.8% and a diameter of 2.2mm. Potassium humate urea.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com