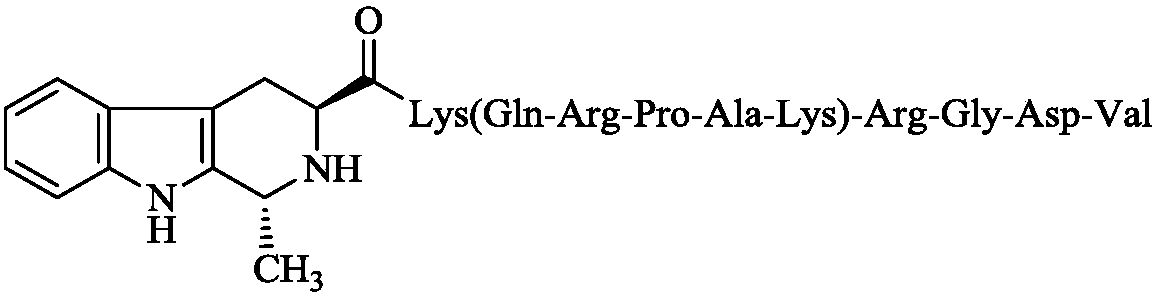

1R-methyl-beta-tetrahydrocarbolineacyl-K(QRPAK)-RGDV, and synthesis, activity and application thereof

A -arg-gly-asp-val, methyl technology, applied in 1R-methyl-β-tetrahydrocarbolinyl-K(QRPAK)-RGDV, its synthesis, activity and application fields, can solve the difficulty of preservation , sensitive to reducing environment, difficult preparation and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

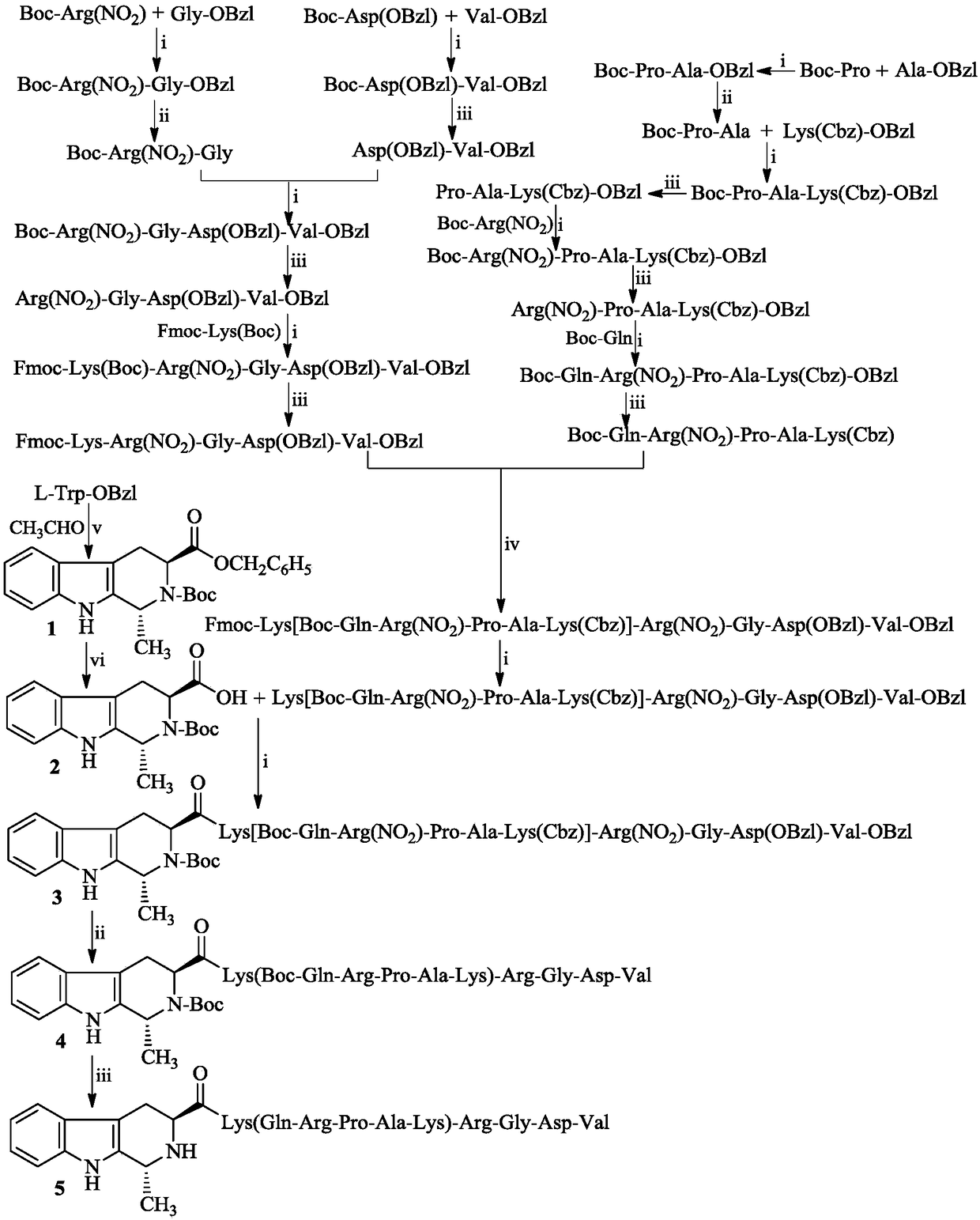

Method used

Image

Examples

Embodiment 1

[0016] Example 1 Preparation of 1-methyl-1,2,3,4-tetrahydro-β-carboline-3-carboxylic acid benzyl ester

[0017] At 60° C., 1 mL of 98% concentrated sulfuric acid was added dropwise to 800 mL of distilled water, and after stirring, 10.0 g (34 mmol) of L-Trp-OBzl was added in three times. Stir for five minutes to fully suspend L-Trp-OBzl and sulfuric acid aqueous solution. After that, 10 mL of 40% acetaldehyde aqueous solution was added dropwise to the suspension. The reaction mixture was first stirred at 60°C for 12 hours, and then 3 mL of concentrated ammonia was added dropwise to adjust the pH of the reaction solution to 8. The reaction compound is allowed to stand for 1 hour, and the product is fully analyzed. The solid was filtered and dried to obtain 9.84 g (90%) of a pale yellow solid, which was 1R-methyl-1,2,3,4-tetrahydro-β-carboline-3S-carboxylic acid benzyl ester and 1S-methyl -A mixture of 1,2,3,4-tetrahydro-β-carboline-3S-carboxylic acid benzyl ester. ESI-MS(m / e):3...

Embodiment 2

[0018] Example 2 Preparation of N-Boc-1-methyl-1,2,3,4-tetrahydro-β-carboline-3-carboxylic acid benzyl ester (1)

[0019] The 9.84 g (30.8 mmol) 1-methyl-1,2,3,4-tetrahydro-β-carboline-3-carboxylic acid benzyl ester obtained in Example 1 was used with 20 mL of N,N-dimethylformamide ( DMF) dissolved. Add 6.98g (32.0mmol) Boc to the solution at 0℃ 2 O. The resulting solution was adjusted to pH 12 with triethylamine and stirred at room temperature for 48 hours. The reaction mixture was concentrated under reduced pressure to remove DMF. The residue was dissolved with 100 mL ethyl acetate. The obtained ethyl acetate solution was washed with 5% potassium hydrogen sulfate aqueous solution (50 mL×3) and saturated sodium chloride aqueous solution (50 mL×3) successively. The separated ethyl acetate layer was dried over anhydrous sodium sulfate for 12 h, filtered, and the filtrate was concentrated under reduced pressure to obtain an oily substance. The oil was separated with a silica g...

Embodiment 3

[0022] Example 3 Preparation of Boc-1R-methyl-1,2,3,4-tetrahydro-β-carboline-3S-carboxylic acid (2)

[0023] Add 100mg Pd / C to 1g (2.38mmol) N-Boc-1R-methyl-1,2,3,4-tetrahydro-β-carboline-3S-benzyl carboxylate and 40mL anhydrous tetrahydrofuran , Stir to make a uniform suspension. The air in the reaction system was evacuated under reduced pressure, hydrogen was introduced, and stirred at room temperature for 10 hours. TLC (dichloromethane / methanol, 40 / 1) showed N-Boc-1R-methyl-1,2,3,4-tetrahydro- β-carboline-3S-carboxylic acid benzyl ester disappeared completely. Pd / C was removed by filtration, and the filtrate was concentrated under reduced pressure. The ESI-MS (m / e) of the colorless powder obtained was 329[M-H] - .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com