Photoluminescent material

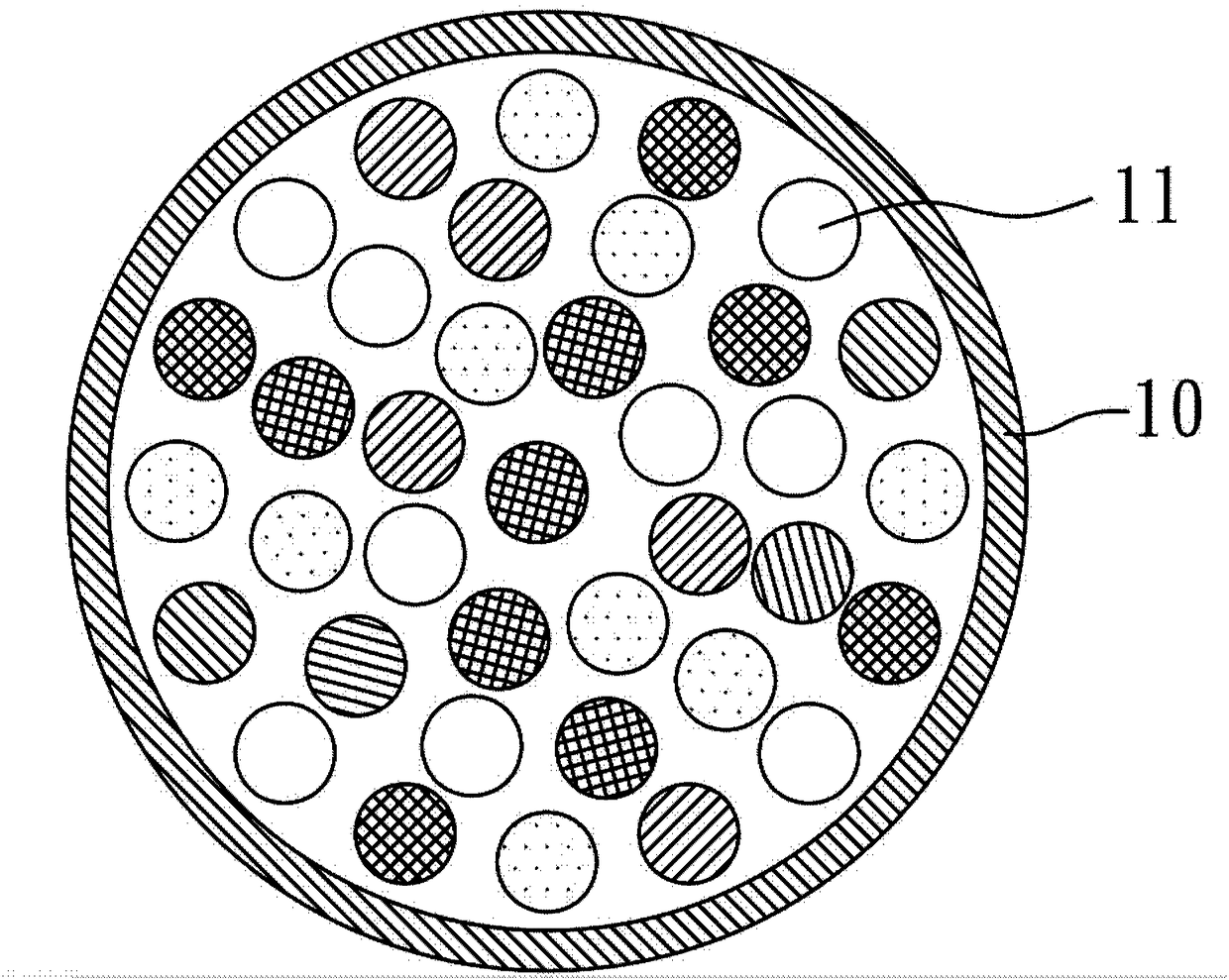

A technology of photoluminescent materials and phosphors, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of uneven mixing of phosphors, uneven light mixing, and reduced uniformity of light output, and achieve enhanced white light color temperature and Color rendering, uniform light mixing effect, and high light uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] First, formulate the mix with Y 2 o 3 : La 3+ , YAG: La 3+ , and phosphor powder mixed aqueous solution of CdSe / ZnS quantum dots, wherein, Y 2 o 3 : La 3+ Yellow light can be emitted after being irradiated by blue light-emitting diodes, YAG: La 3+ After being irradiated by a blue light-emitting diode, it can emit yellow light, while CdSe / ZnS quantum dots can absorb UV light to emit positive white light. After detection by an integrating sphere, the ratio of each phosphor powder is adjusted to obtain a phosphor powder mixed solution with a predetermined color temperature and color rendering property. In this embodiment, the obtained fluorescent powder mixed solution emits white light (color temperature=5500K) after being irradiated by a blue light-emitting diode.

[0037] Next, ammonia water (NH 4 OH), ethanol, and water were mixed and stirred for 5 minutes. Then, tetraethylorthosilicate (TEOS) was added as an initiator, and stirred at constant temperature for 4...

Embodiment 2

[0040] First, formulate Y 2 o 3 : Eu 3+ , Y 2 o 3 : Yb 3+ , Y 2 o 3 : Ce 3+ , and YAG: Ce 3+ Phosphor powder mixed aqueous solution, wherein, Y 2 o 3 : Eu 3+ After being irradiated by a blue light-emitting diode, it can emit red light, Y 2 o 3 : Yb 3+ Can emit green light, Y 2 o 3 : Ce 3+ Can emit blue light, and YAG: Ce 3+ May emit yellow light. After being detected by the integrating sphere, the ratio of each phosphor powder is adjusted to obtain a phosphor powder mixed solution with a predetermined color temperature and color rendering property. In this embodiment, the obtained fluorescent powder mixed solution can emit white light (color temperature=5500K) after being irradiated by a blue light emitting diode.

[0041] Next, ammonia water (NH 4 OH), ethanol and water were mixed and stirred for 5 minutes. Then, TEOS was added as an initiator and stirred at constant temperature for 4 hours. In SiO 2 When the core carrier is about to be condensed and fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com