A kind of engineering bacterium and its application in producing l-tyrosine

The technology of tyrosine and tyrosine phenol is applied in the field of bioengineering, which can solve the problems of easy decomposition of pyruvic acid and low efficiency, and achieve the effects of high NAD content, simple production process and good industrial application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

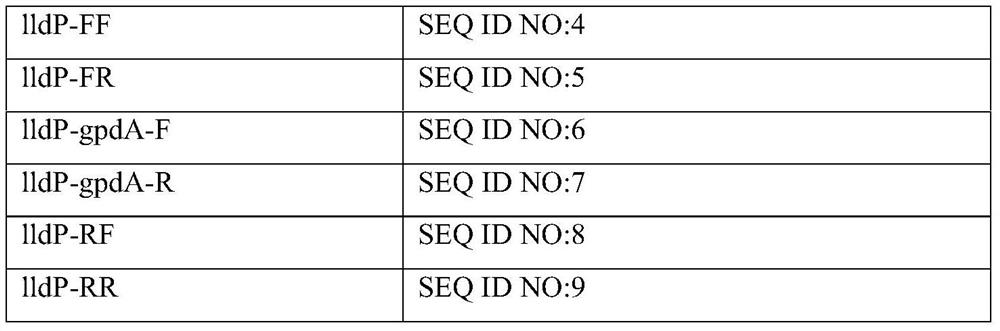

[0062] According to the method described in the literature Large scale validation of an efficient CRISPR / Cas-based multigene editing protocol in Escherichia coli. Microbial Cell Factories, 2017, 16(1): 68, hpaD and mhpB on Escherichia coli BL21 (DE3) were singled out Or double knockout, wherein, the gene knockout plasmid used in the present invention is pCasRed and pCRISPR-gDNA (hpaD sgRNA) and homologous arm (hpaDdonor) are introduced together on Escherichia coli BL21 (DE3), Cas9 / sgRNA induces host in hpaD gene A double-strand break occurred at the site, and the recombinase Red integrated the hpaD donor into the hpaD gene to achieve gene knockout, which was verified by sequencing. hpaD sgRNA, hpaD donor, mhpB sgRNA, and mhpB donor are respectively shown in the sequence listing SEQ ID NO:11, SEQ ID NO:12, SEQ ID NO:13, and SEQ ID NO:14. mhpB was knocked out in the same way.

[0063] Prepare a solution with a pH of 8, 1 g / L of phenol or L-tyrosine, 100 g / L of wet bacteria, and...

Embodiment 2

[0068] Recombinant Escherichia coli construction: First, the genes encoding lactate dehydrogenase, NADH oxidase, and tyrosine phenolic acid lyase were respectively connected to the plasmid pETDuet-1. After obtaining various three-gene co-expression recombinant plasmids, the plasmids were transformed into Escherichia coli HM, and positive transformants were obtained by screening with ampicillin plate, that is, recombinant Escherichia coli was obtained.

[0069] Induced expression method: the recombinant Escherichia coli is transferred to LB fermentation medium (peptone 10g / L, yeast powder 5g / L, NaCl 10g / L) in the amount of 2% by volume ratio, when the cell OD 600 After reaching 0.6-0.8, add IPTG with a final concentration of 0.4mM, induce expression and culture at 20°C for 8h. After induction of expression, the cells were collected by centrifugation at 20° C., 8000 rpm, and 20 minutes.

[0070] The collected cells were analyzed for transformation, and the results are shown in ...

Embodiment 3

[0075] According to the strain construction method described in Example 2 (various types of plasmids were selected according to the instructions using different resistance plates to screen positive transformants) and induced expression method, various types of cells were collected for transformation analysis, and the results are shown in Table 3. The whole cell transformation system in the transformation system is: cell wet weight 50g / L, L-lactic acid 10g / L, phenol 10g / L, pH 7.0, temperature 30°C, shaker speed 250 rpm; transformation time 10 hours.

[0076] The various expression plasmids of table 3 are for the comparison of producing L-tyrosine

[0077] strain L-Tyrosineg / L Escherichia coli HM / pETDuet-1-llnox-llldh-cftpl 6.3 Escherichia coli HM / pACYCDuet-1-llnox-llldh-cftpl 4.3 Escherichia coli HM / pCOLADuet-1-llnox-llldh-cftpl 5.7 Escherichia coli HM / pRSFDuet-1-llnox-llldh-cftpl 5.3 Escherichia coli HM / pCDFDuet-1-llnox-llldh-cftpl 4.8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com