Saturated steam generation device

A technology of steam generating device and steam pipe, which is applied in the field of steaming machines, can solve the problems of troublesome dirt, large floor area of the machine, and large boiling water tank, etc., and achieves the goal of reducing later-stage costs, floor space, and convenient maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

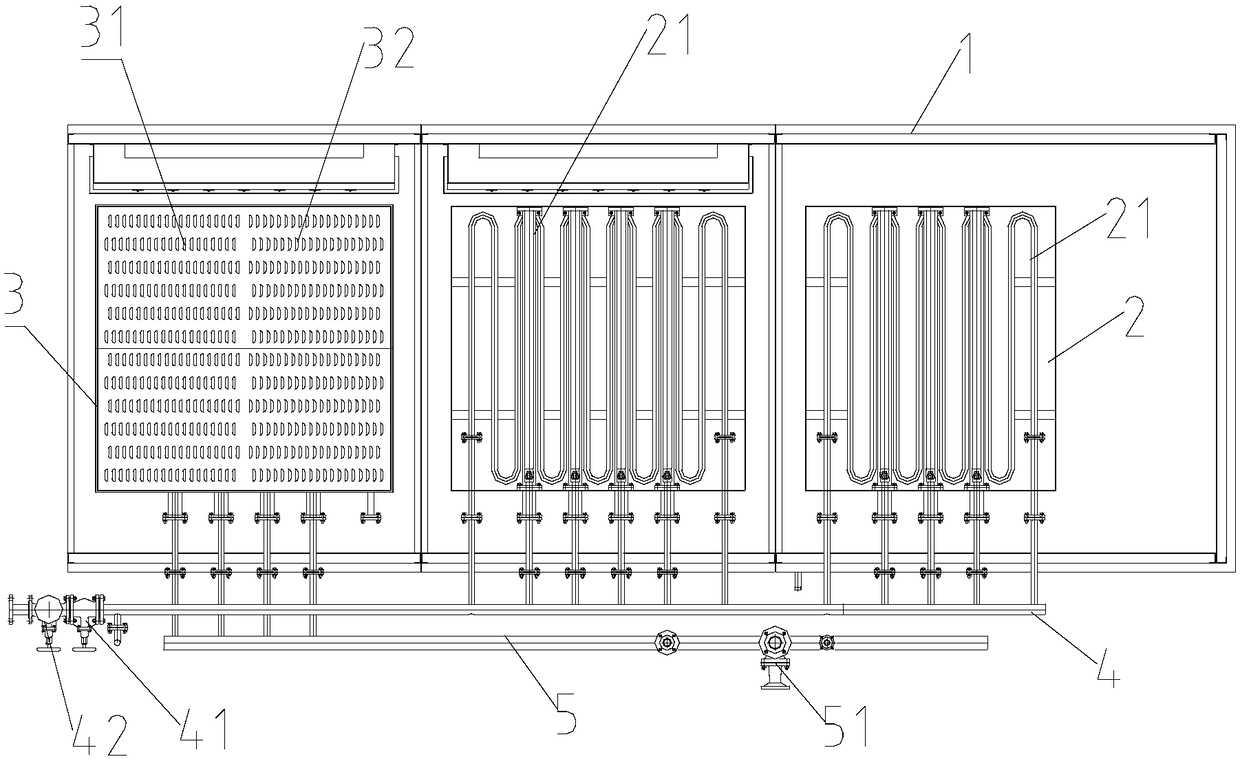

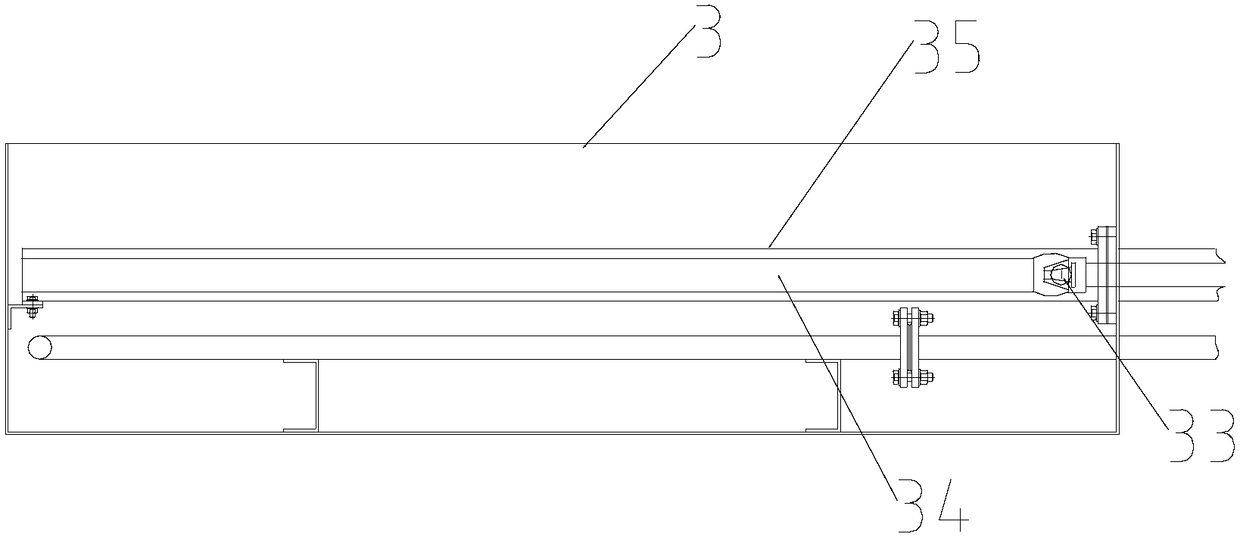

[0025] Such as figure 1 The illustrated saturated steam generating device of the present invention includes one or more heating water tanks 2 and / or steam spraying water tanks 3 arranged at the bottom of the steamer 1 and communicated with the steamer 1, and the supplied steam passes through Its connection enters in the steamer 1, and a plurality of heating water tanks 2 can be set, and a plurality of steam spraying water tanks 3 can also be set, and both can be set, specifically set the quantity according to the size of the steamer 1, the present invention will The heating water tank 2 and / or the steam spraying water tank 3 are set at the bottom instead of inside the steamer 1, which makes maintenance more convenient and reduces the later cost, and instead of setting up a large water tank like the traditional one, set up multiple separate heating The water tank 2 or the steam spraying water tank 3 can effectively reduce the occupied area and reduce the overall volume of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com