A prefabricated board with pre-embedded lighting optical fiber

A prefabricated panel and optical fiber technology, applied in the field of building materials, can solve the problems of dim light, increased lighting power consumption, poor physical and mental health, etc., and achieve the effects of easy installation and replacement, avoiding leakage, and reducing injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

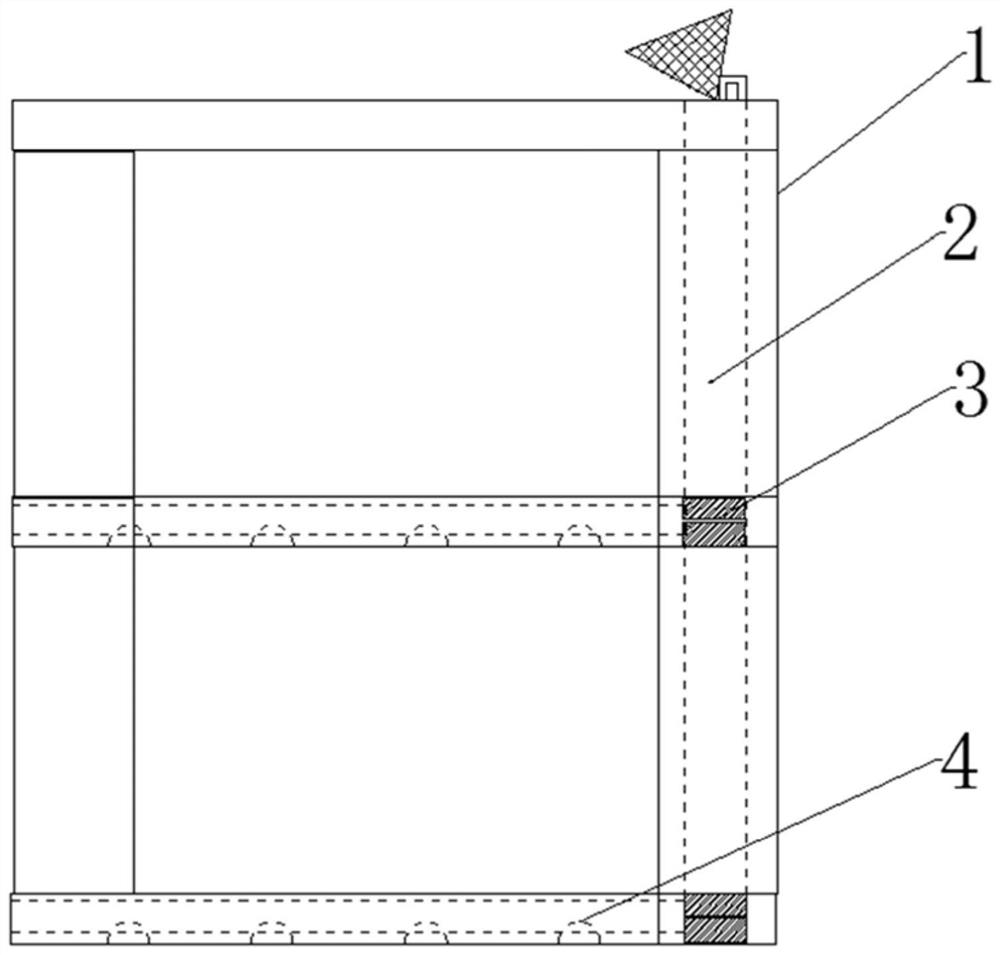

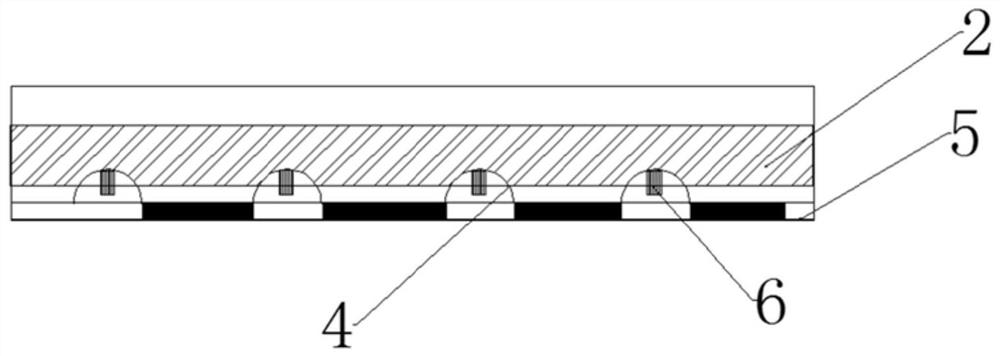

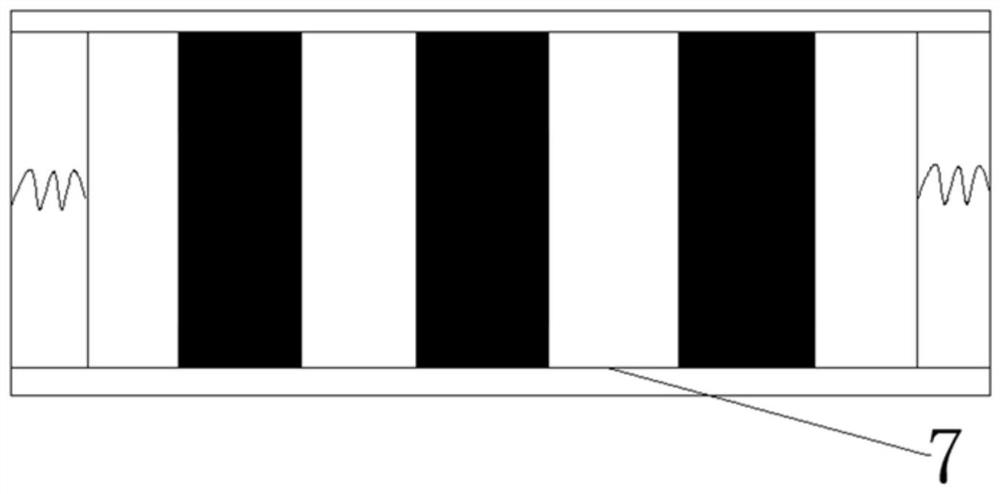

[0018] A prefabricated panel for pre-embedding lighting optical fibers, comprising a prefabricated panel 1, a light source collection component used in conjunction with the prefabricated panel, an optical fiber transmission pipe 2 is arranged inside the prefabricated panel, and a light source exporting part is arranged on the surface of the prefabricated panel; There is an optical fiber bundle 6; the prefabricated board includes a transmission prefabricated board and a terminal prefabricated board, at least one side of the transmission prefabricated board is provided with an optical fiber transmission pipe, and the inner wall of the optical fiber transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com