High-air-tightness pipe fitting applied to exhaust gas treatment air duct system

A technology for waste gas treatment and high air tightness, applied in the direction of pipes/pipe joints/fittings, rigid pipes, pipe components, etc., which can solve noise pollution, environmental and enterprise worker pollution and injury, and pipe fittings cannot achieve the air tightness of metal parts. and other problems, to achieve the effect of high air-tight waste gas transportation, reducing the leakage of toxic and harmful gases, and high air-tightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

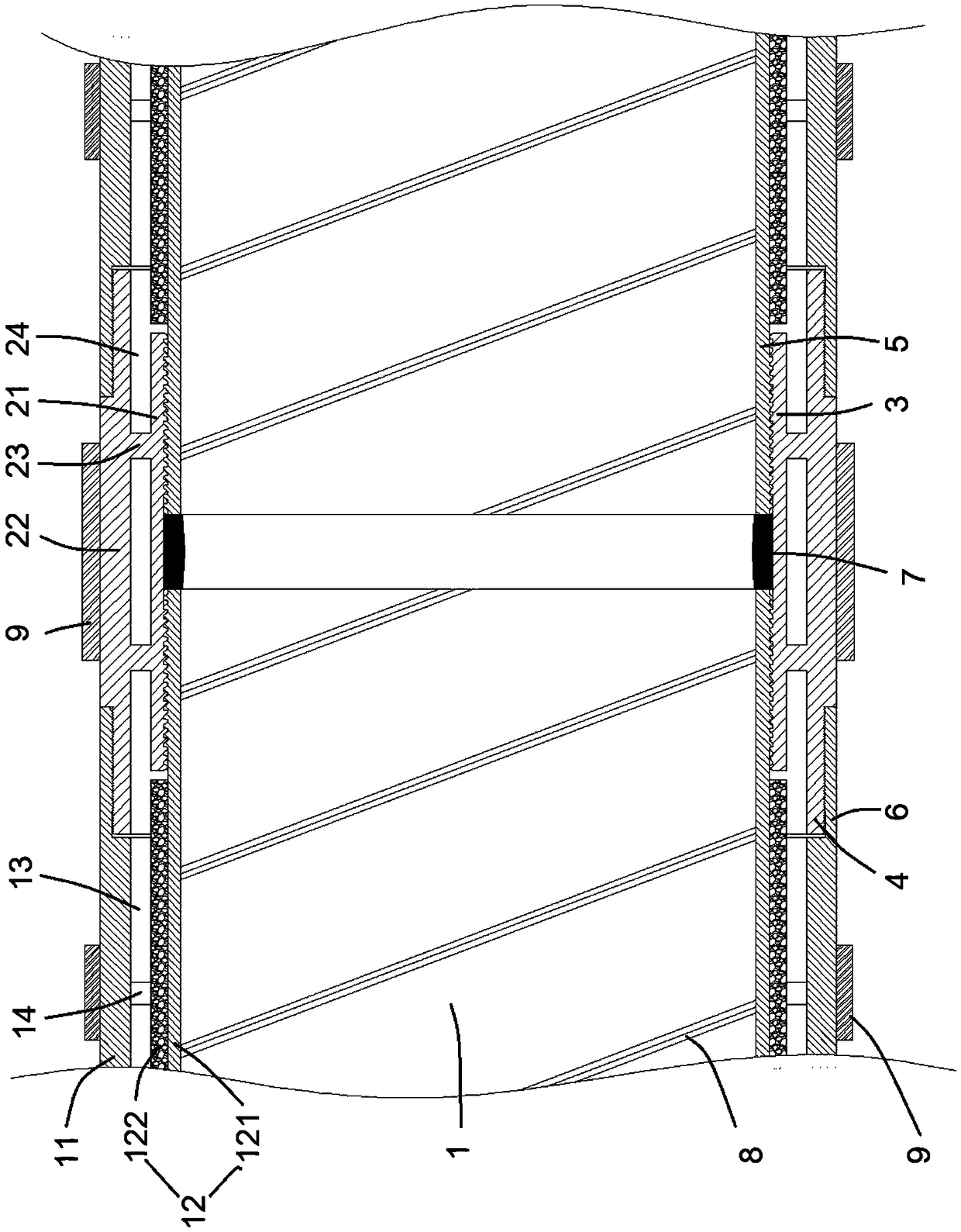

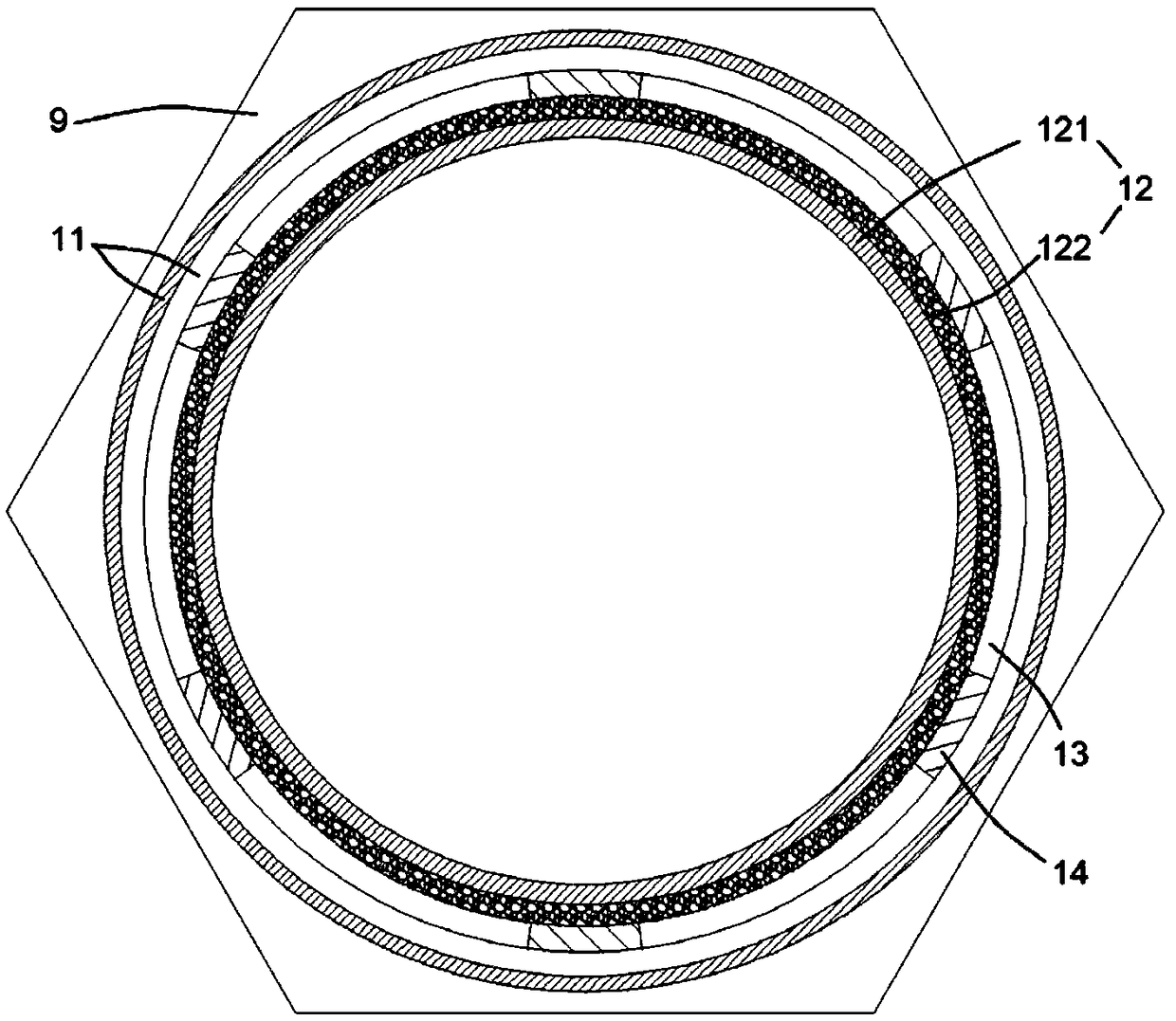

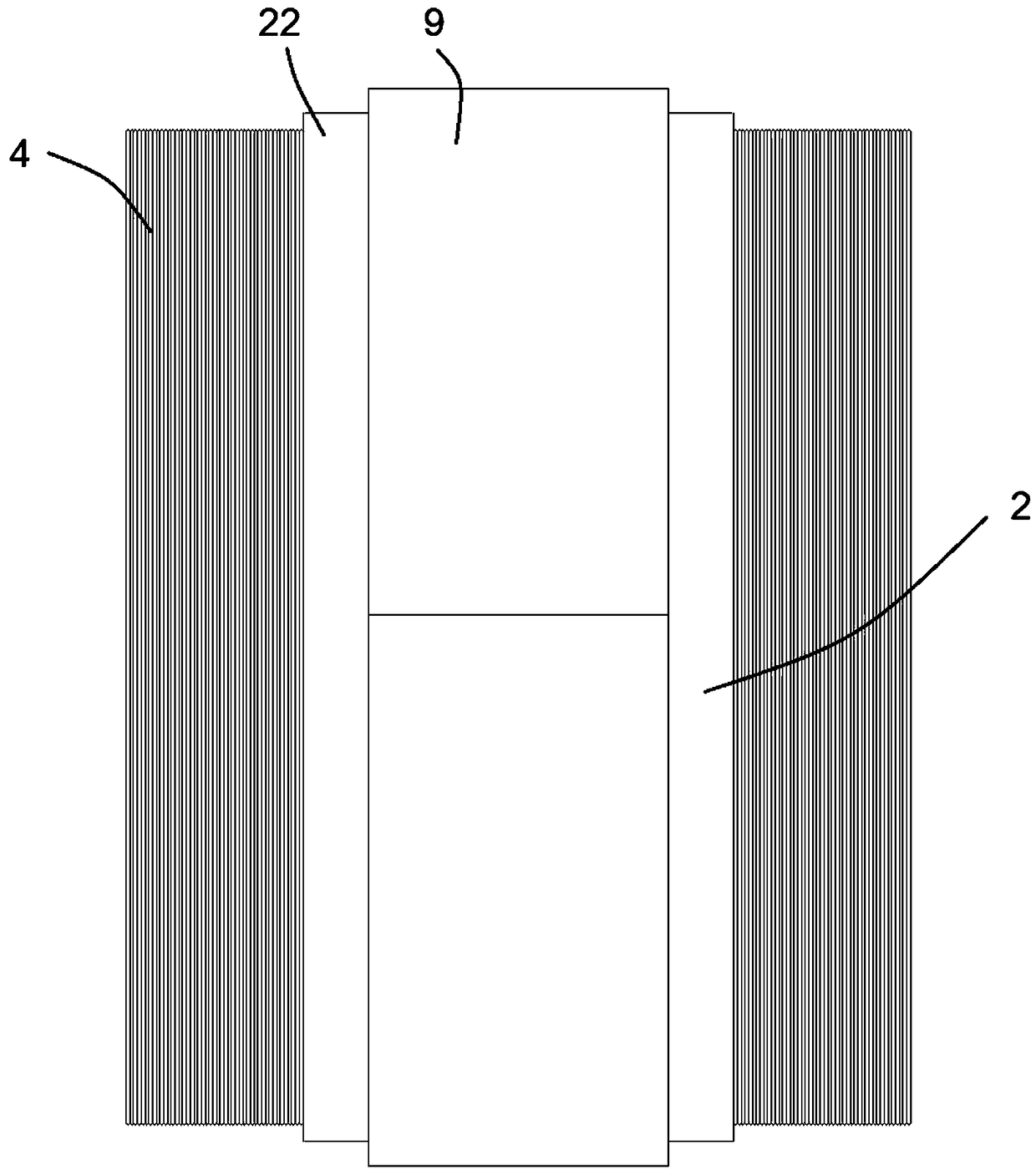

[0031] Such as Figure 1-4 Shown is a high airtight pipe fitting applied to the exhaust gas treatment air duct system, including an air pipe 1 and a joint 2 for connecting the air pipe 1, and the feature is that the air pipe 1 includes an outer pipe layer 11 and an inner pipe layer 11 Tube layer 12, a hollow layer 13 is provided between the outer tube layer 11 and the inner tube layer 12, and several connecting ribs 14 are arranged between the outer tube layer 11 and the inner tube layer 12 along the axial direction of the air duct 1, and the joint 2 includes an inner connection layer 21 and an outer connection layer 22, and several connecting ribs 23 are arranged between the inner connection layer 21 and the outer connection layer 22 along the axial direction of the joint 2, and the connection ribs 23 are connected to the inner connection layer 21 and the outer connection layer 22. A hollow channel 24 is formed, and the two ends of the inner layer 21 and the outer layer 22 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com