A low-resistance self-adaptive suction flow control device and method with silencing function

A low-resistance, self-adaptive technology, applied in the direction of pipe components, mechanical equipment, pipes/pipe joints/fittings, etc., can solve the problems of not considering the flow resistance of the catheter, and can not meet the application of adaptive suction technology, so as to reduce the flow Exciting noise, good self-adaptive function, and the effect of reducing flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

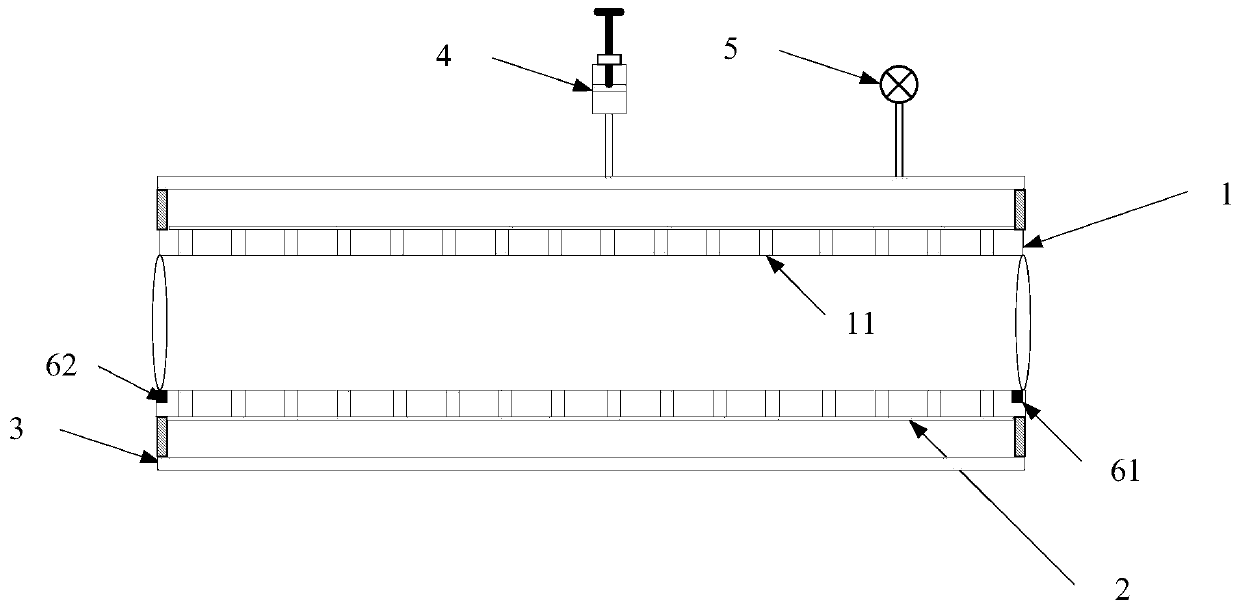

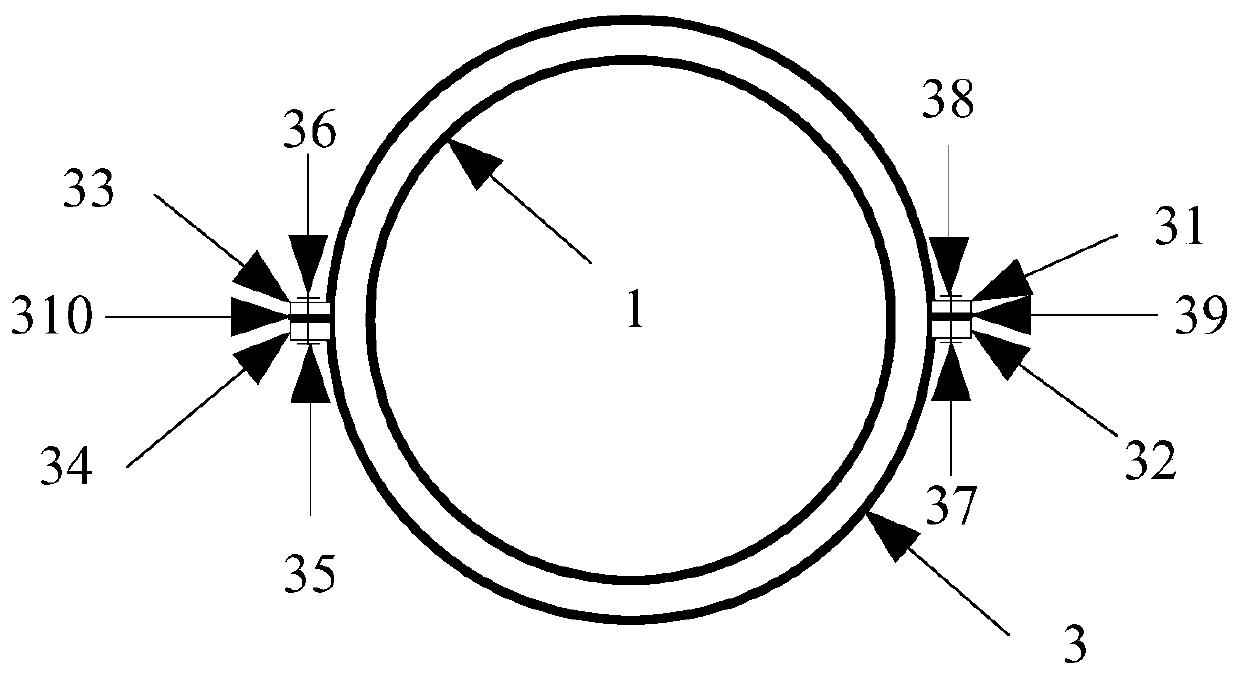

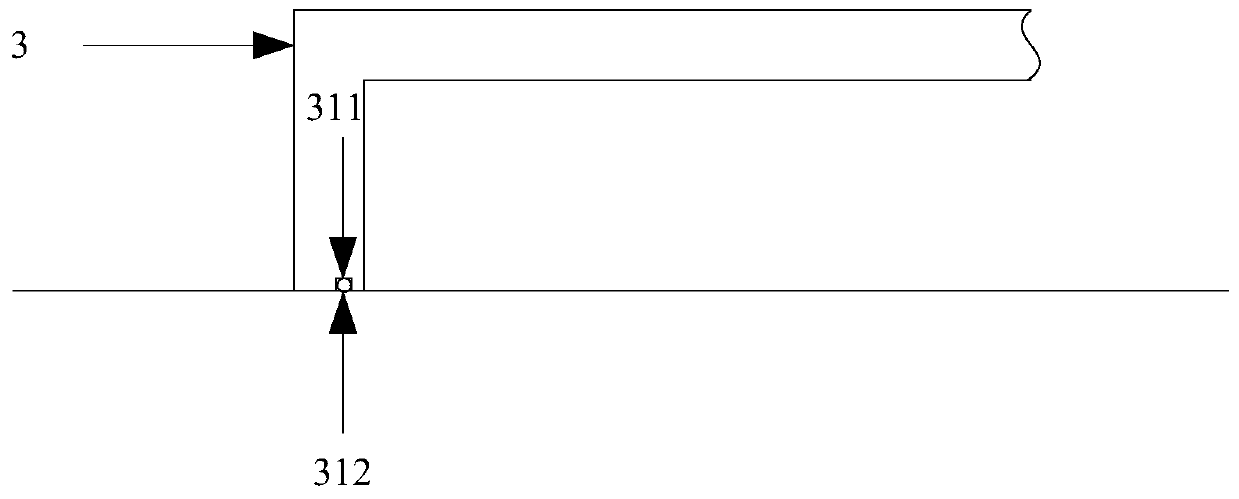

[0026] A low-resistance self-adaptive suction flow control device with noise reduction function, comprising a circular tube 1, a film 2, a sleeve 3, a pressurizer 4, a pressure gauge 5, an inlet-end pressure sensor 61 and an outlet-end pressure sensor 62;

[0027] Among them, the round tube 1 is made of stainless steel, the thickness of the tube wall is between 1 mm and 3 mm, and a small through hole is opened on the surface of the round tube 1 according to a perforation rate of 4%, and the diameter of the small through hole is 0.5 to 0.9 mm. between;

[0028] Film 2 is a PET silica gel film with a thickness of 0.02 mm. The Young’s modulus, density and Poisson’s ratio are measured by experimental methods, and the film 2 is modeled in the Comsol multi-physics software to analyze the tensile properties of the film 2. Obtain the surface tension coefficient of film 2;

[0029...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com