Automatic control method for transformation process of supercritical or ultra-supercritical unit from hygrometric state to dry state

An ultra-supercritical unit and supercritical technology, which is applied in the control system, water supply control, preheating, etc., can solve the problems of uneven operation level of power plant operators, large load fluctuations, and overheating of steam temperature, and achieve slow changes in unit parameters. , The effect of smooth transition of working conditions and improvement of operation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

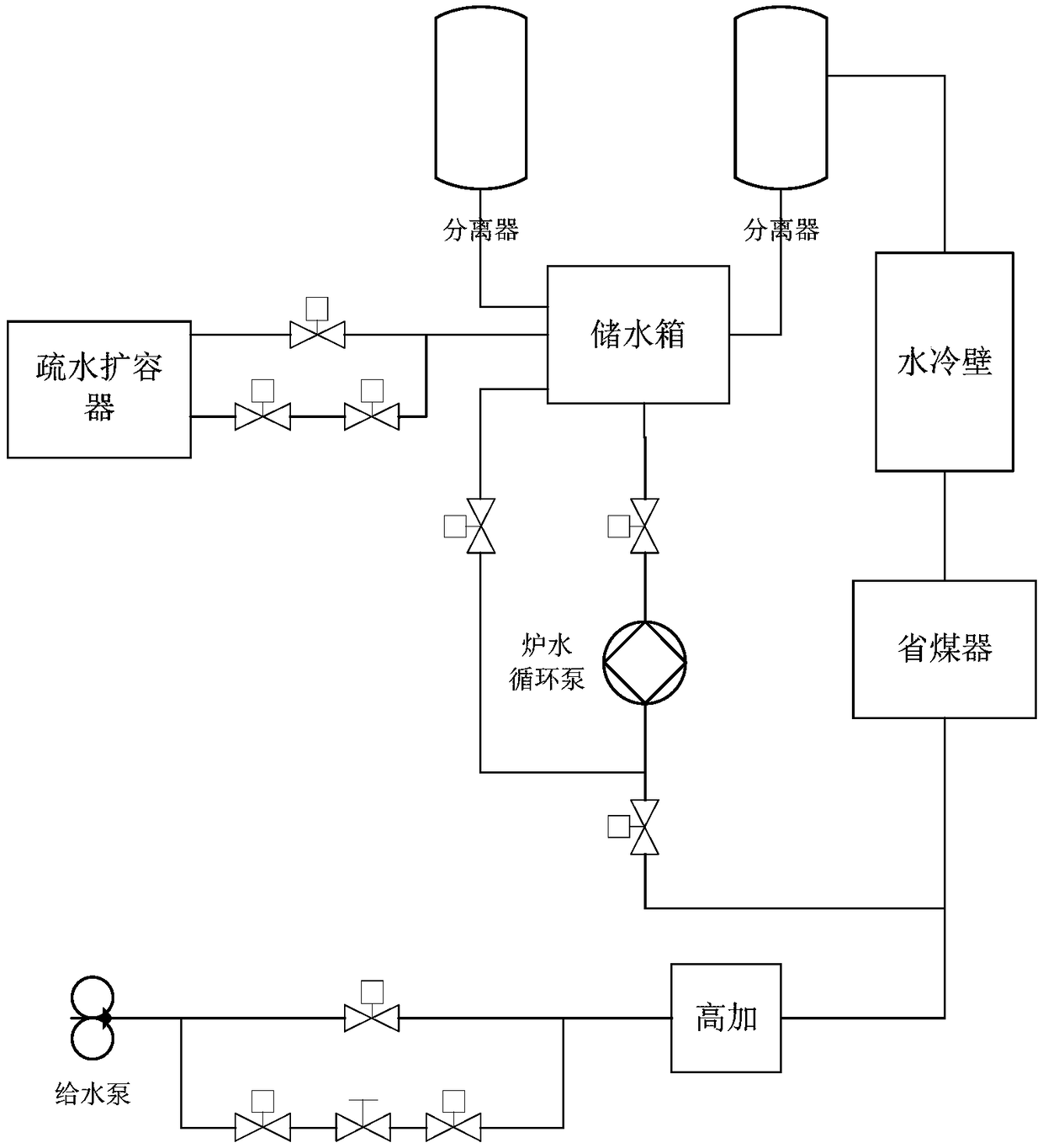

[0037] Below with reference to accompanying drawing, further illustrate the present invention.

[0038] The method for automatic control of the transition from wet state to dry state of a super (super) critical unit according to the present invention comprises the following steps.

[0039]Step 1: Confirm that the unit has met the dry-wet state conversion conditions, and start the dry-wet state automatic conversion control logic. For once-through boilers of ultra (super)critical units manufactured by different manufacturers, the timing of dry-wet state conversion is different. For example, the 1000MW ultra-supercritical unit of the third phase of Guodian Power Beilun Power Plant turns to dry state at 25-27% BMCR load. Zhejiang Huaneng The 1000MW ultra-supercritical unit of Yuhuan Power Plant turns dry when the load is 34% BMCR, and the 1000MW ultra-supercritical unit of Zhejiang Zheneng Taier Power Plant turns dry when the load is 35-40% BMCR. In order to make the dry-wet tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com