Rotating device for large aperture optical flat mirror in absolute detection

A technology of rotating device and optical plane, applied in the field of optical measurement, to achieve the effect of simple device structure and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with drawings and embodiments.

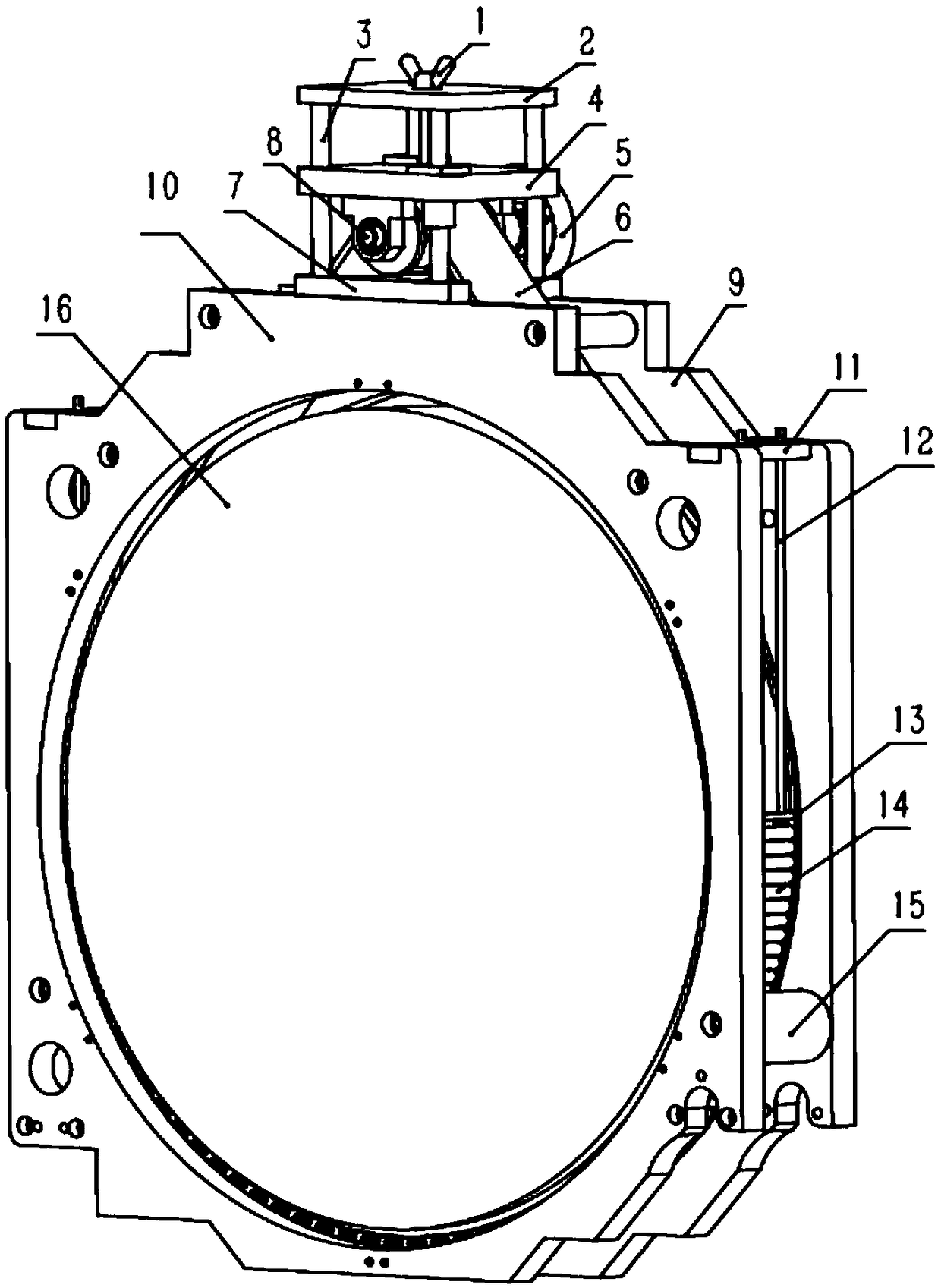

[0018] figure 1 It is a structural diagram of the rotating device used for absolute detection of medium and large-diameter optical planes according to the present invention. It can be seen from the figure that the device of the present invention includes a lifting and rotating mechanism, a hoisting and rotating mechanism and a mirror frame;

[0019] The picture frame is composed of a rear plate 9 and a front plate 10 parallel to each other and connected by a plurality of limit connecting rods 15 around;

[0020] The lifting and rotating mechanism includes a wing nut 1, a first flat plate 2, a support rod 3, a supporting flat plate 4, a rotating hand wheel 5, a soft-toothed synchronous belt 6, a base plate 7 and a rotating shaft 8; the first flat plate 2 , the supporting plate 4 and the bottom plate 7 are linked together through a plurality of supporting rods 3 parallel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com