Steel barrel leakage detector

A technology for steel drums and leaking machines, which is applied in the direction of detecting the appearance of fluid at the leaking point and using liquid/vacuum degree for liquid tightness measurement, etc., to achieve the effects of simple structure, reduced labor intensity, and high processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

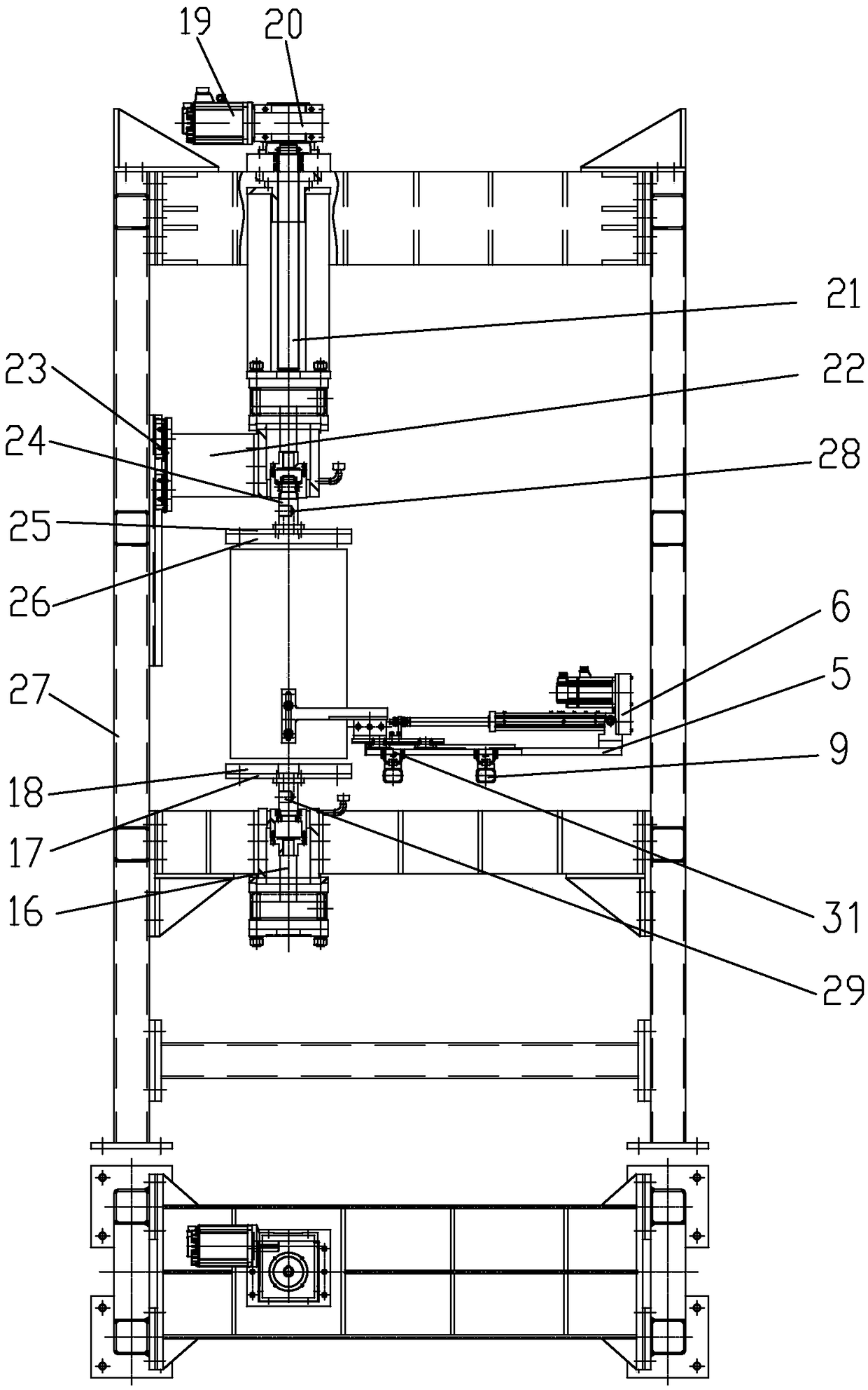

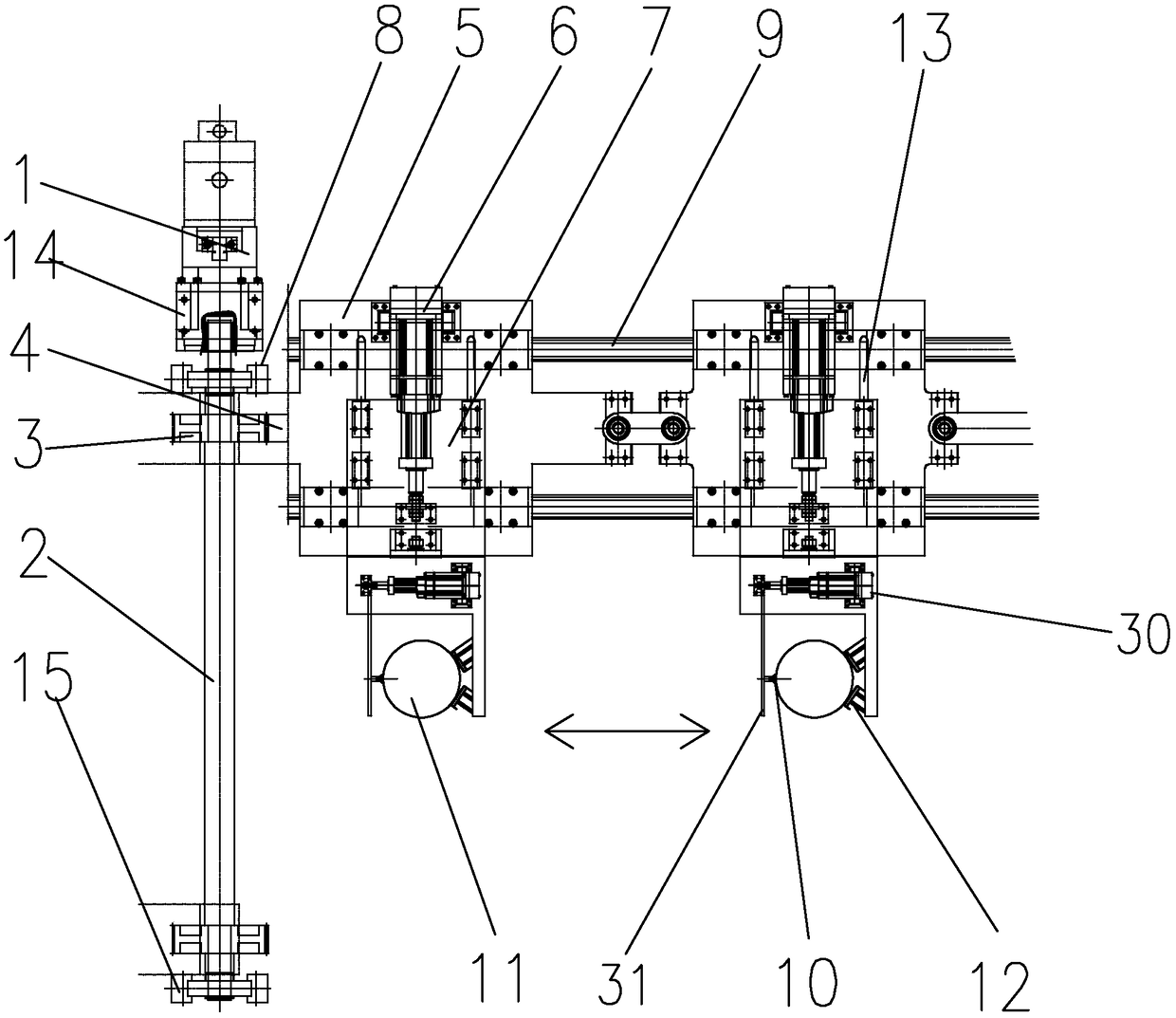

[0016] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0017] Figure 1-2 Among them, servo motor 1, transmission shaft 2, gear 3, rack 4, large slide 5, electric cylinder 6, small slide 7, reducer base 8, horizontal linear guide 9, vacuum suction cup 10, steel drum 11, V Type block 12, longitudinal linear guide rail 13, reducer 14, bearing housing 15, lower lift cylinder 16, lower connecting plate 17, lower rubber pressure plate 18, upper servo motor 19, upper reducer 20, upper screw rod 21, nut seat 22. Guide rail 23, upper lifting cylinder 24, upper connecting plate 25, upper rubber pressure plate 26, frame 27, upper air pipe interface 28, lower air pipe interface 29, lateral movement cylinder 30, lateral movement slider 31, etc.

[0018] like Figure 1-2 As shown, the present invention is a steel drum leak detection machine, including a frame 27, an upper leak detection mechanism is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com