Intelligent motor capable of realizing self monitoring and self maintenance

An intelligent motor and self-monitoring technology, which is applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve problems such as strong randomness of manual maintenance methods, wrong fault judgments, unexpected production shutdowns, etc., achieving significant progress and industrial practicality value, low maintenance costs, and the effect of reducing serious consequences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

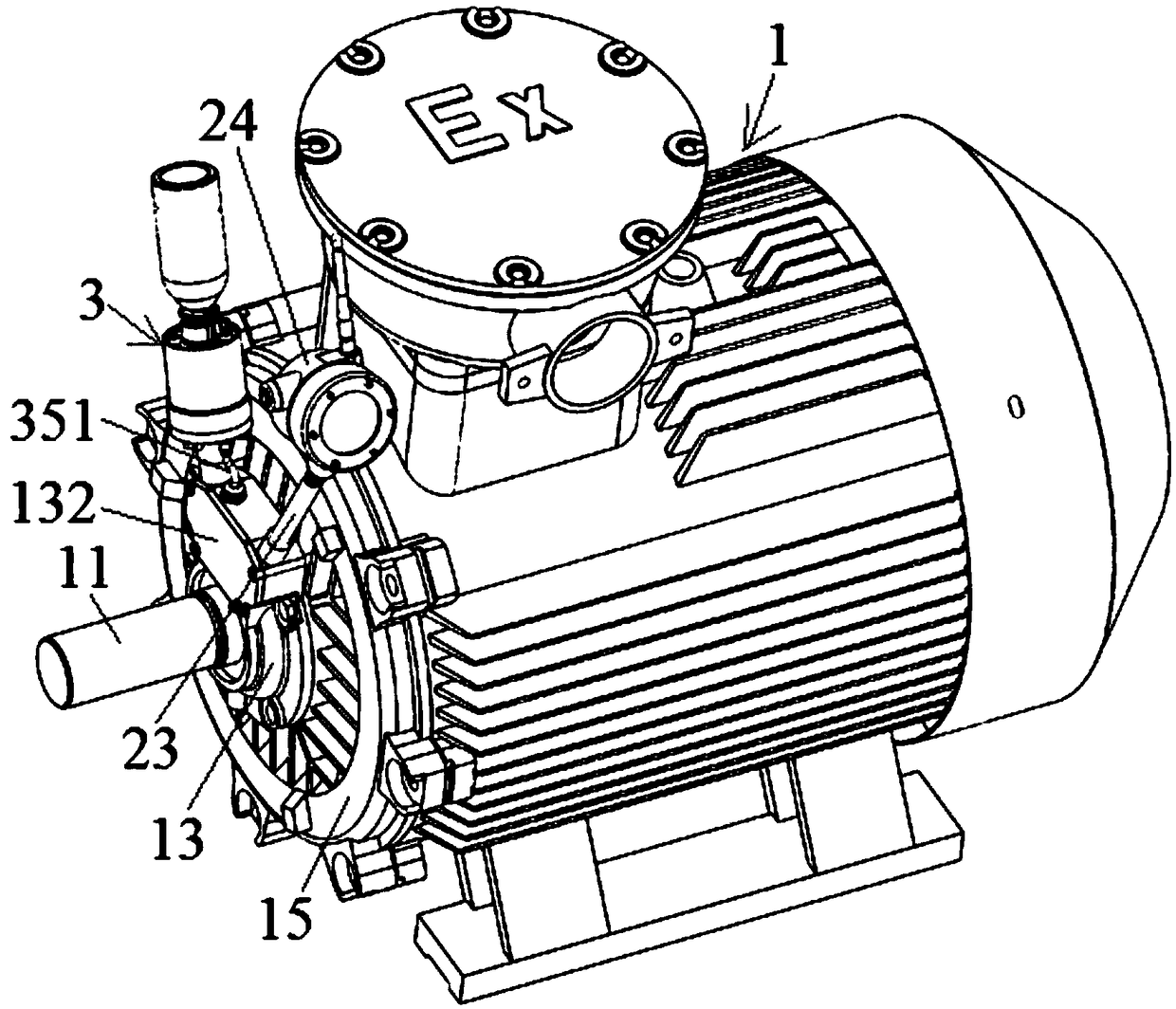

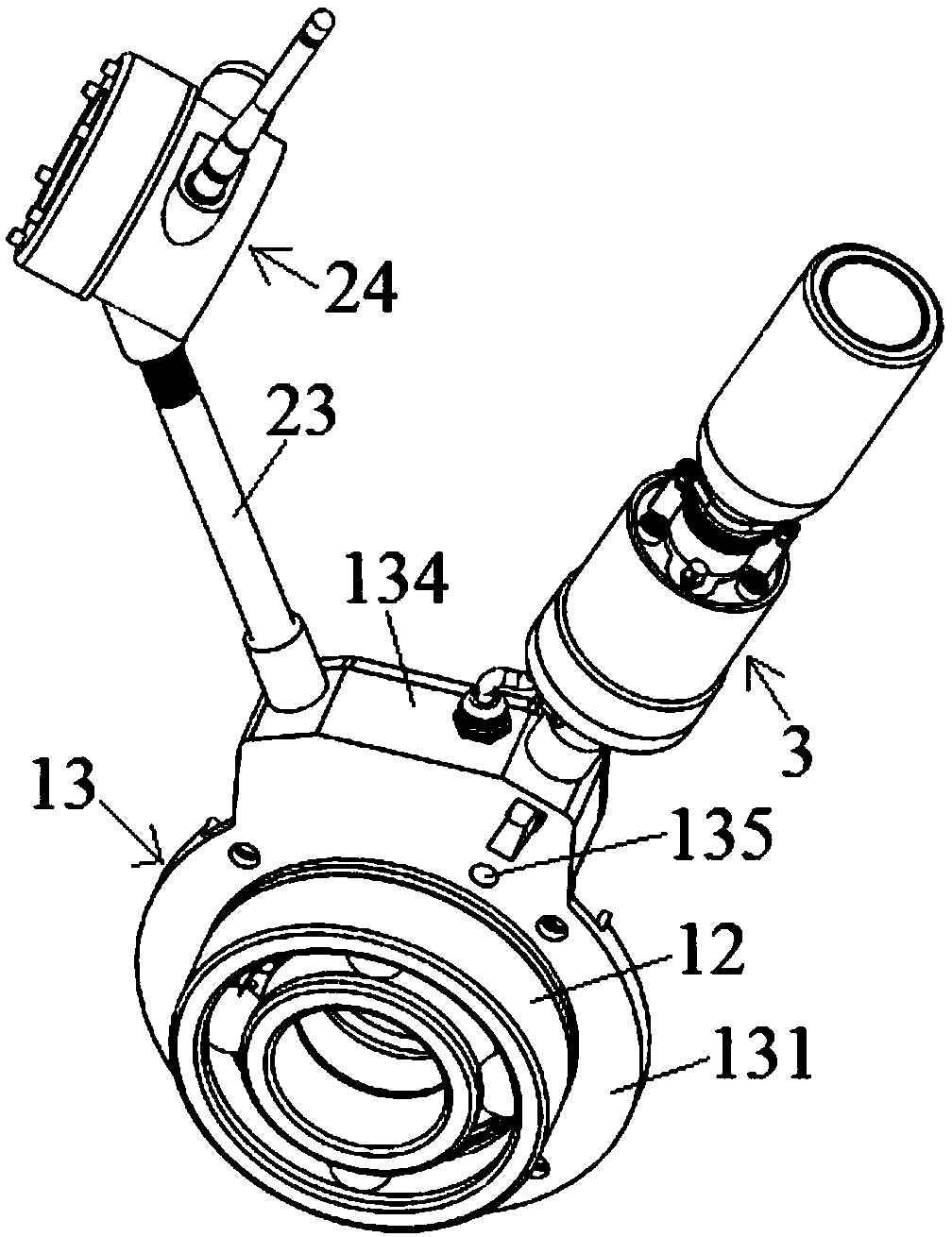

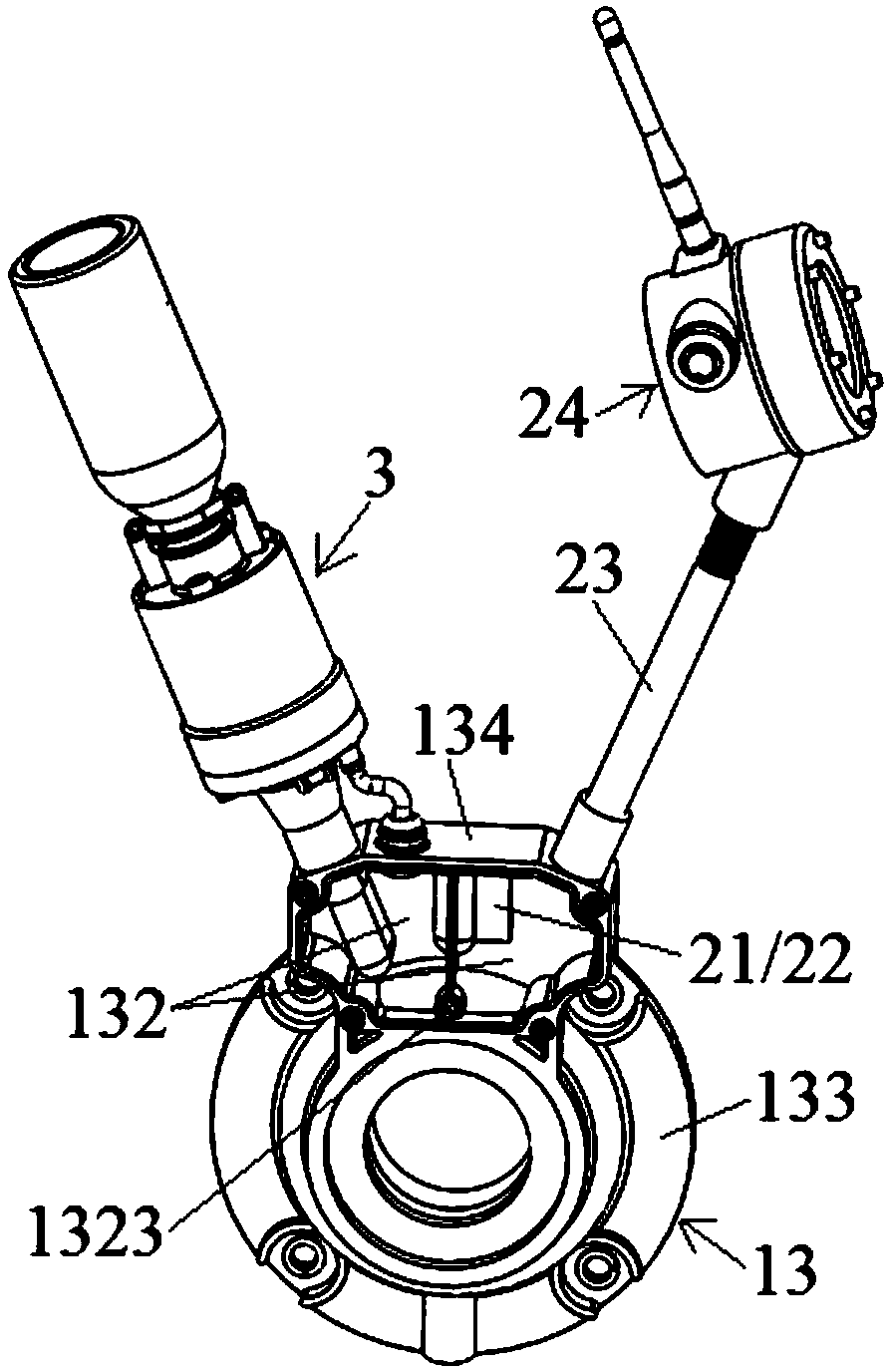

[0056] Please combine Figure 1 to Figure 5 As shown: an intelligent motor capable of online self-monitoring and self-maintenance provided by this embodiment includes a motor body 1, a self-monitoring system 2, an automatic oiling device 3 and a self-power supply mechanism 4, and the motor body 1 includes a rotating shaft 11 , bearing 12, bearing outer end cover 13, bearing inner end cover 14 and motor end cover 15, the bearing 12 is sleeved on the rotating shaft 11, the motor end cover 15 is sleeved on the bearing 12, and is located on the bearing 12 The bearing outer end cover 13 on the outer end side and the bearing inner end cover 14 located on the inner end side of the bearing 12 are respectively fixedly connected; the self-monitoring system 2 includes a temperature sensor 21 and a vibration sensor 22, and the automatic oiling device 3 includes an oiling motor 31( Figure 1-5 not shown in ), the self-power supply mechanism 4 includes a magnet fixed disk 41 and a coil win...

Embodiment 2

[0072] The purpose of this embodiment is to provide a kind of automatic oiling device 3 with explosion-proof function, please refer to Figure 16 As shown, the difference between the automatic oiling device 3 described in this embodiment and the automatic oiling device described in Embodiment 1 is that the upper casing 34 and the base 35 are connected by a flameproof joint surface M1, The upper part of the oil passage 36 is connected with the upper casing 34 by a flameproof joint surface M2, and the lower part of the oil passage 36 is connected with the base 35 in a flameproof manner (in this embodiment, an internal thread is provided on the threaded hole 352 , the bottom of the oil passage 36 is provided with an external thread, so that the bottom of the oil passage 36 and the threaded hole 352 are connected by an explosion-proof thread W1); and, on the piston rod 381, a shaft sleeve 3811 is connected with an explosion-proof thread ( That is: the shaft sleeve 3811 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com