Roll-type coil used for camera, making method and use method of roll-type coil and coil assembly

A production method and camera technology, which is applied in the field of cameras, can solve the problems of non-disclosure and cooperation, and achieve the effect of large electromagnetic driving force, large number of coil turns, and improved optical anti-shake performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

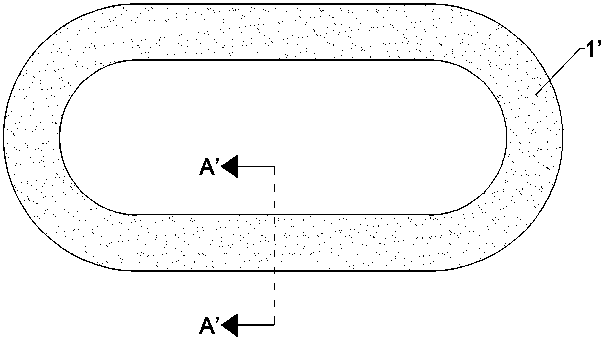

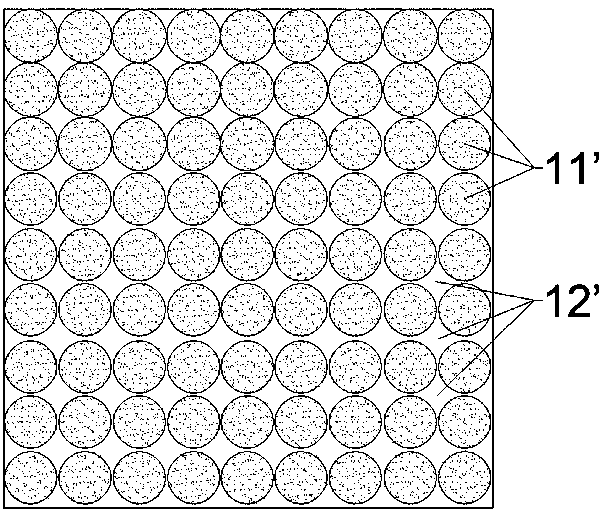

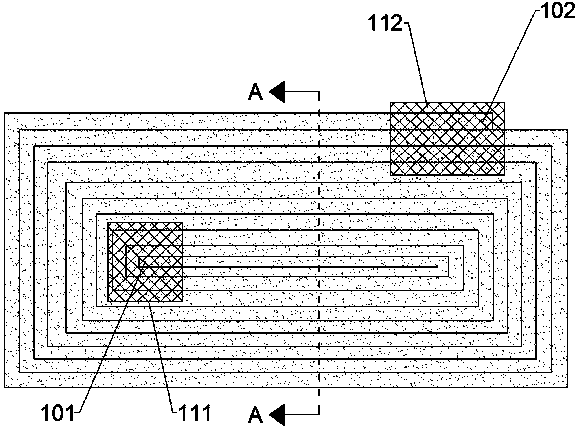

[0034] Such as image 3 with 4 As shown, a winding coil 1 for a camera is formed by coiling a conductive sheet 11 with an insulating layer on the surface to form a winding structure, and the conductive sheet 11 on one end surface is exposed as a conductive terminal.

[0035] The wound coil 1 adopts a rectangular conductive sheet 11 coiled to form a wound structure, and there is no gap between adjacent conductive sheets 11. Compared with the traditional copper wire coil, the density of the conductive material is higher, and the coil turns More numbers, greater electromagnetic driving force, especially suitable for OIS coils to improve the optical image stabilization performance of OIS motors.

[0036] In use, the conductive sheet 11 needs to be exposed from the insulating layer on one end surface of the wound coil 1 as a conductive end, and assembled with a circuit board or other connecting terminals to form an electrical connection. Such as image 3 As shown, the conductive...

Embodiment 2

[0043] Such as Figure 5 As shown, a method for manufacturing the wound coil 1 for a camera described in Embodiment 1 includes:

[0044] Step 1: Provide surface with insulating layer such as Image 6 A conductive sheet 11 shown;

[0045] This step 1 specifically includes:

[0046] Step 1.1: providing a conductive sheet 11;

[0047] In this step 1.1, the conductive sheet 11 may be a metal foil or a conductive film.

[0048] Step 1.2: making an insulating layer on the surface of the conductive sheet 11 .

[0049] In this step 1.2, the insulating layer can be insulating ink or insulating paint.

[0050]Since the wound coil 1 needs to expose the conductive sheet 11 from the insulating layer on one end surface during use as a conductive end, and assemble it with a circuit board or other connection terminals to form an electrical connection, therefore, In this step 1.2, in a specific implementation manner, when the insulating layer is made on the conductive sheet 11, the side ...

Embodiment 3

[0063] A method of using the wound coil 1 for a camera described in Embodiment 1, which is used as an OIS coil for an OIS motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com