Recovery device for gas-liquid separation of tail gas

A gas-liquid separation and recovery device technology, which is applied in the direction of combined devices, separation methods, and dispersed particle separation, can solve the problems of easy failure of the wire mesh demister, overload of the recovery device, and failure to meet the collection requirements of aromatics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

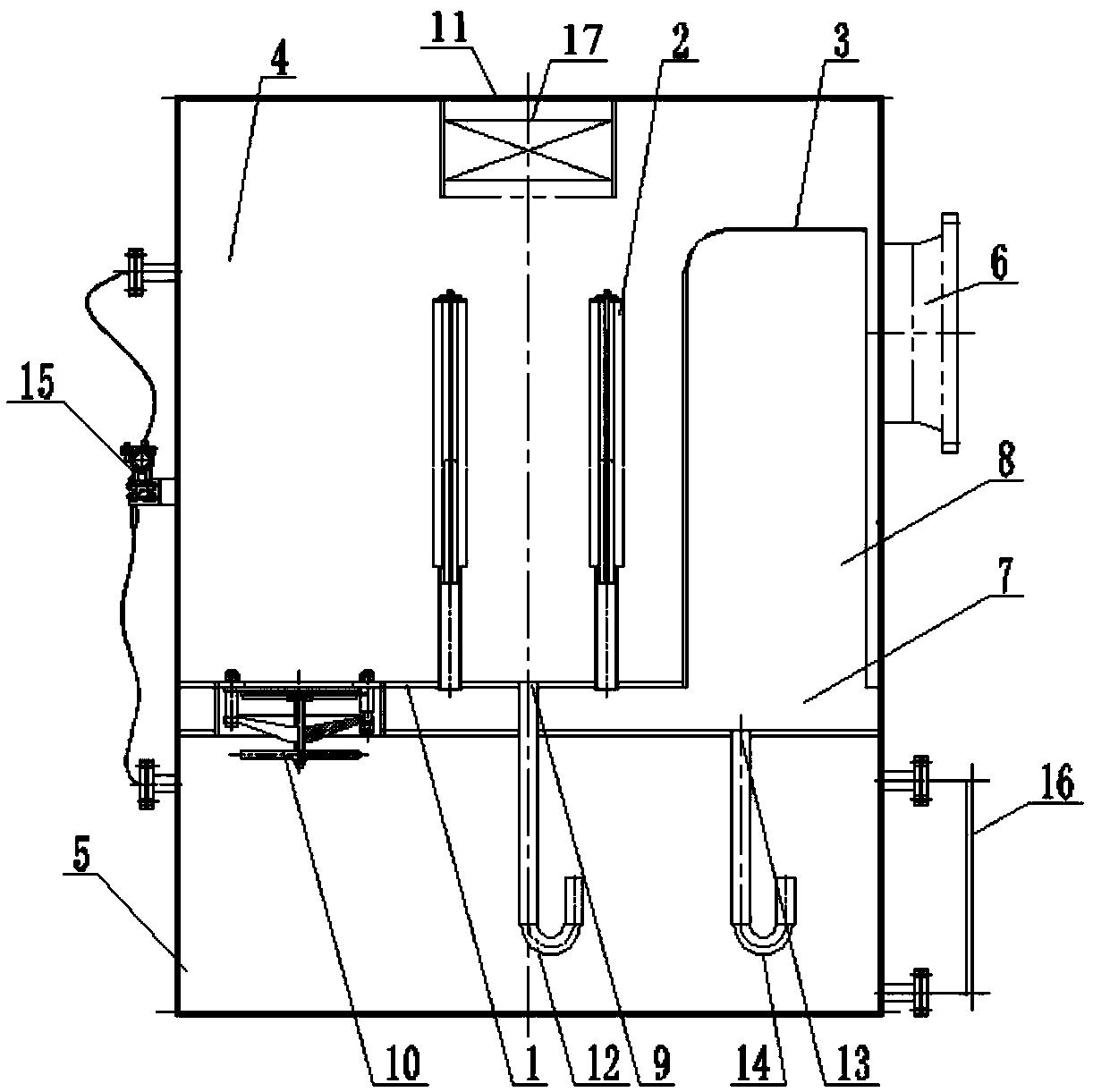

[0027] figure 1 A recovery device for gas-liquid separation tail gas is shown, including a cylinder body, a hollow partition 1, at least one recovery filter element 2 and several sealing baffles 3, and the inner wall of the cylinder is provided with a hollow partition 1 The cylinder is divided into an upper cylinder 4 and a lower cylinder 5 by a hollow partition 1, an air inlet 6 is opened on the side wall of the upper cylinder 4, and a communication port is provided on the top surface of the hollow partition 1. The inner cavity of the upper cylinder body 4 and the air inlet 7 of the inner cavity of the hollow partition 1 are provided with an air inlet passage 8 formed by...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap