Lettering device for packaging box

A packaging box and operating table technology, applied in the field of engraving equipment for packaging boxes, can solve the problems of low environmental protection performance, poor stability, low work efficiency, etc., so as to improve work efficiency and work quality, improve stability, enhance The effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

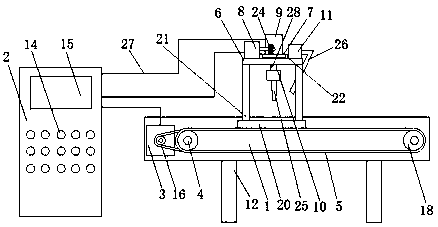

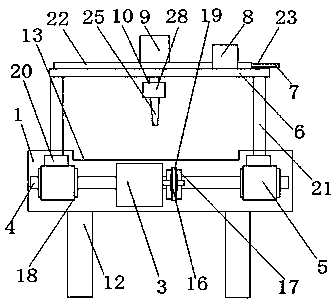

[0015] as attached figure 1 with 2 Shown: a lettering equipment for packing boxes, including console 1, control cabinet 2, motor one 3, rotating shaft 4, transmission belt 5, bearing plate 6, adjustment plate 7, motor two 8, cylinder 9, lettering The motor 10 and the vacuum motor 11 are characterized in that: the console 1 is set on the bracket 12, and a bearing slot 13 is arranged on the console 1, and the control cabinet 2 is set on one side of the console 1 , and the control cabinet 2 is provided with an operation button 14 and a control panel 15, the motor one 3 is arranged in the console 1, and the motor one 3 is provided with a driving wheel 16, and the rotating shaft 4 is arranged on the In the console 1, a driving wheel 17 and a rotating wheel 18 are arranged on the rotating shaft 4. The transmission belt 5 is arranged between the rotating wheel 18 and the rotating wheel 18, and a fixed plate 20 is arranged on the transmission belt 5. , the bearing plate 6 is arrange...

Embodiment 2

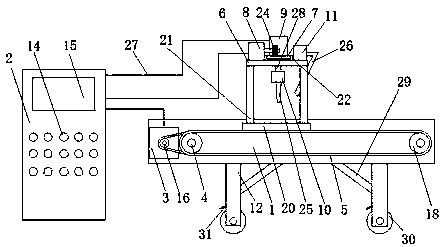

[0020] as attached image 3 Shown: a lettering equipment for packing boxes, including console 1, control cabinet 2, motor one 3, rotating shaft 4, transmission belt 5, bearing plate 6, adjustment plate 7, motor two 8, cylinder 9, lettering The motor 10 and the vacuum motor 11 are characterized in that: the console 1 is set on the bracket 12, and a bearing slot 13 is arranged on the console 1, and the control cabinet 2 is set on one side of the console 1 , and the control cabinet 2 is provided with an operation button 14 and a control panel 15, the motor one 3 is arranged in the console 1, and the motor one 3 is provided with a driving wheel 16, and the rotating shaft 4 is arranged on the In the console 1, a driving wheel 17 and a rotating wheel 18 are arranged on the rotating shaft 4. The transmission belt 5 is arranged between the rotating wheel 18 and the rotating wheel 18, and a fixed plate 20 is arranged on the transmission belt 5. , the bearing plate 6 is arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com