Refining method of DAOAF (3,3'-diamino-4,4'-azoxy furazan) explosive crystal

A technology of azofurazan oxide and diamino, which is applied in 3 fields, can solve the problems of insensitivity to friction and static sparks, and achieve the effect of easy equipment and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

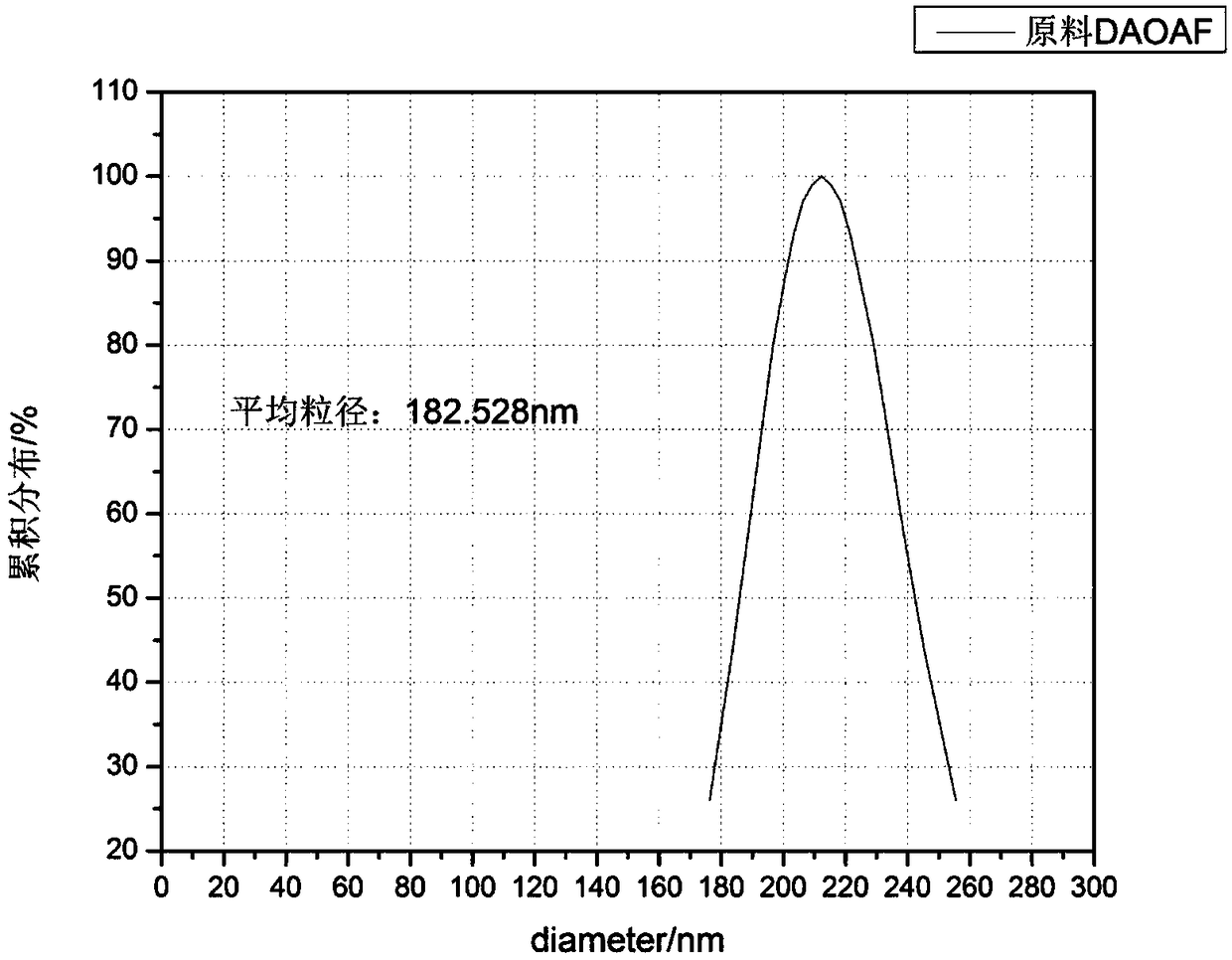

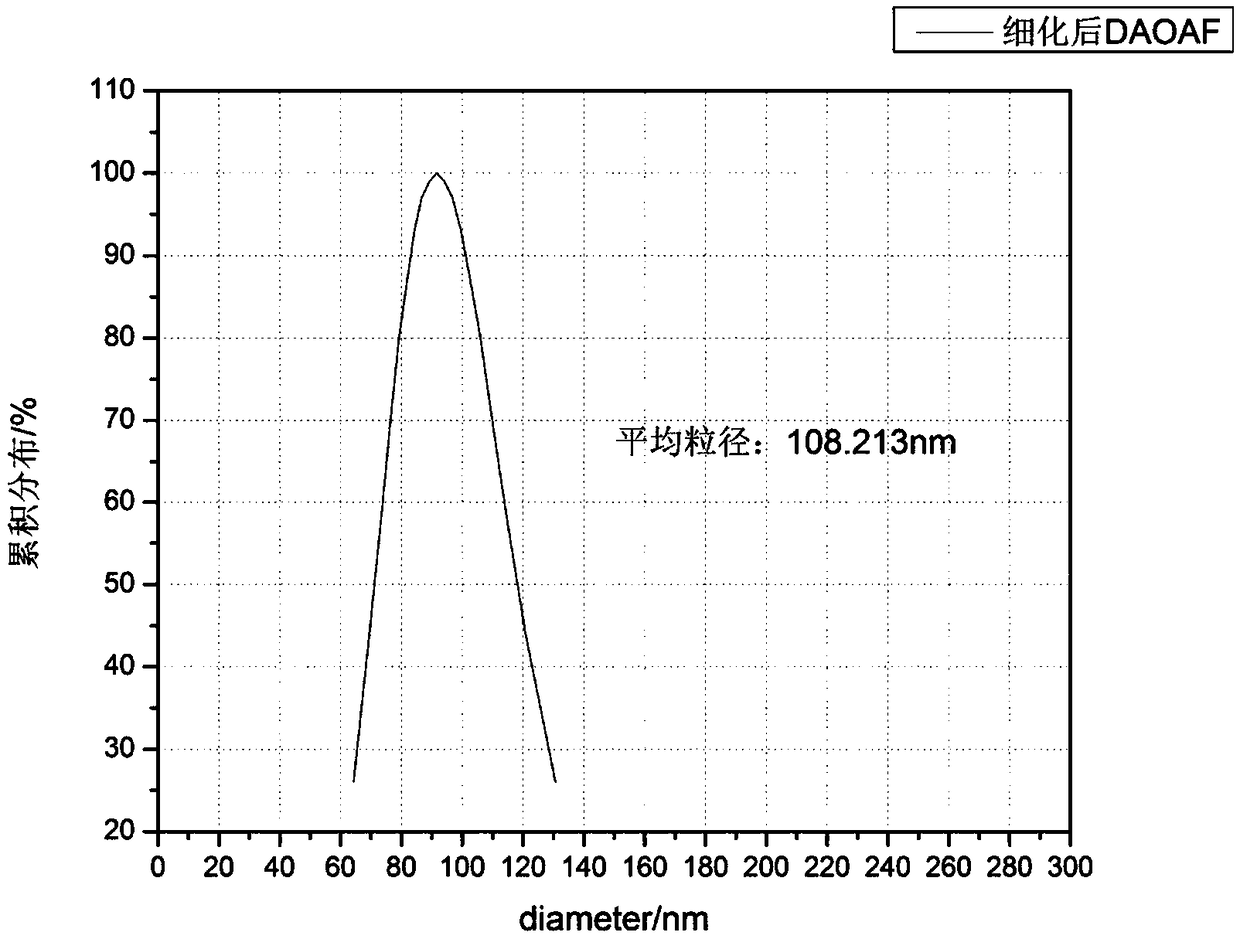

[0035] Firstly, dissolve the raw material DAOAF in dimethyl sulfoxide DMSO, ultrasonicate according to the ratio of DAOAF(g)3:DMSO(ml)11 until it is completely dissolved into a DAOAF solution, and pour the DAOAF solution into an atomizing nozzle with a diameter of 0.8mm .

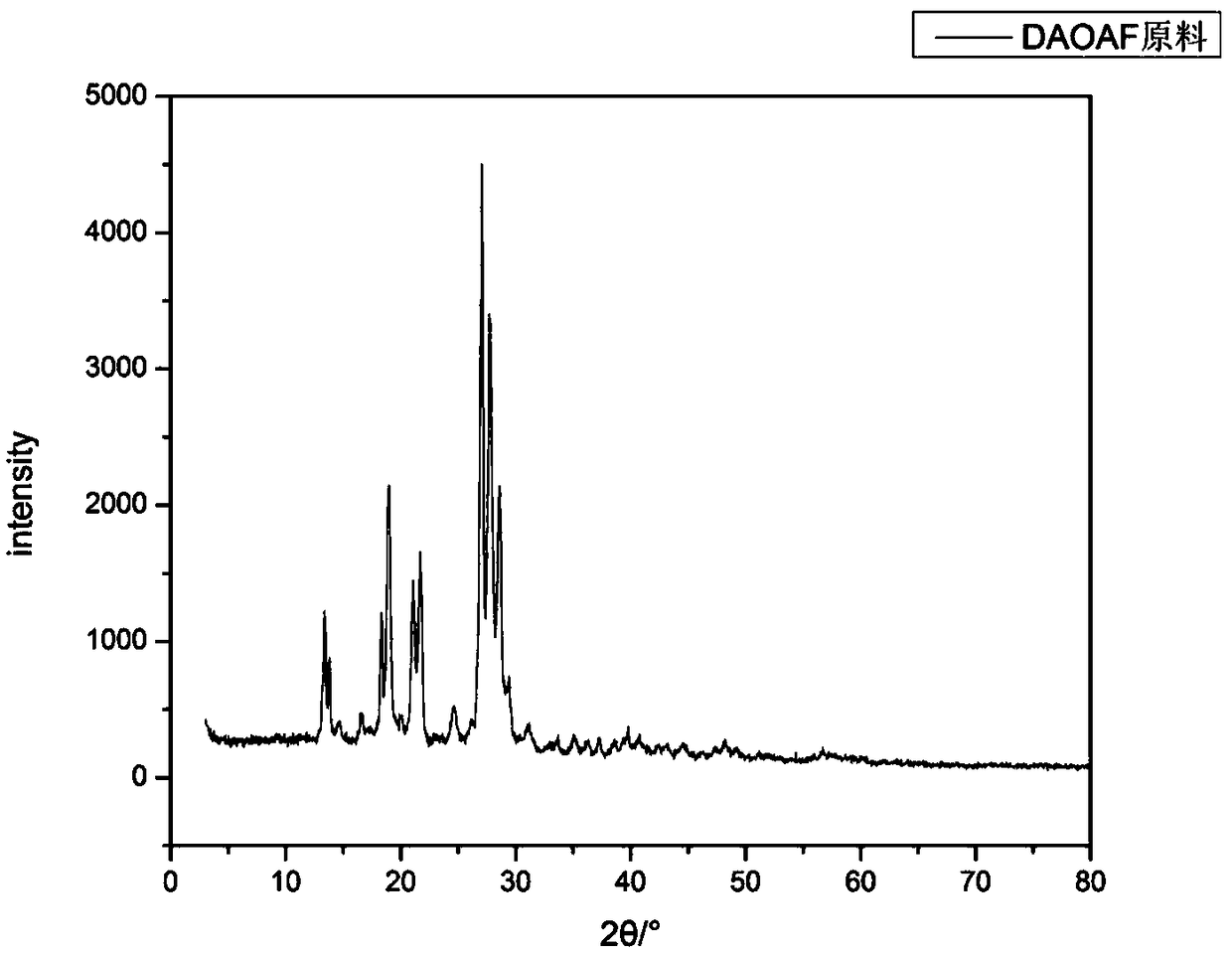

[0036] Then turn on the nitrogen to pressurize, the pressure value is 0.6MPa, make the DAOAF solution pass through the atomization nozzle to form small droplets and contact with non-solvent deionized water, and quickly crystallize and precipitate DAOAF particles, and at the same time, ultrasonic and stir at a stirring speed of 450r / min for 45min . Finally filter and dry in vacuo. The particle size and morphology of recrystallized DAOAF were characterized by laser particle size analyzer and SEM.

Embodiment 2

[0038] First, dissolve the raw material DAOAF and DMSO in DMSO, stir according to DAOAF(g)3:DMSO(ml)11 until completely dissolved into a DAOAF solution, and pour the DAOAF solution into an atomizing nozzle with a diameter of 1mm.

[0039] Then turn on the nitrogen to pressurize, the pressure value is 0.6MPa, make the DAOAF solution pass through the atomization nozzle to form droplets and contact with deionized water, ultrasonic and stir at a stirring speed of 450r / min for 45min. Finally the DAOAF particles are crystallized out and dried. Then use scanning electron microscope, laser particle size analysis and other advanced equipment for analysis and characterization.

[0040] Embodiment two:

[0041] First, dissolve the raw material DAOAF and DMSO in DMSO, stir according to DAOAF(g)3:DMSO(ml)11 until completely dissolved into a DAOAF solution, and pour the DAOAF solution into an atomizing nozzle with a diameter of 1.2mm.

[0042] Then turn on the nitrogen to pressurize, the ...

Embodiment 4

[0044] First, dissolve the raw material DAOAF and DMSO in DMSO, stir according to DAOAF(g)3:DMSO(ml)11 until completely dissolved into a DAOAF solution, and pour the DAOAF solution into an atomizing nozzle with a diameter of 0.8mm.

[0045] Then turn on the nitrogen to pressurize, the pressure value is 0.4MPa, make the DAOAF solution pass through the atomization nozzle to form droplets and contact with deionized water, ultrasonic and stir at a stirring speed of 450r / min for 45min. Finally the DAOAF particles are crystallized out and dried. Then use scanning electron microscope, laser particle size analysis and other advanced equipment for analysis and characterization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com