Polymers based on fluorodithiophene vinyl derivatives and their applications in organic field effect transistors

A technology for polymers and transistors, applied in the fields of organic chemistry, electric solid devices, semiconductor devices, etc., can solve problems such as unsatisfactory performance, and achieve the effect of simple and easy synthesis route, excellent film formation, and excellent thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

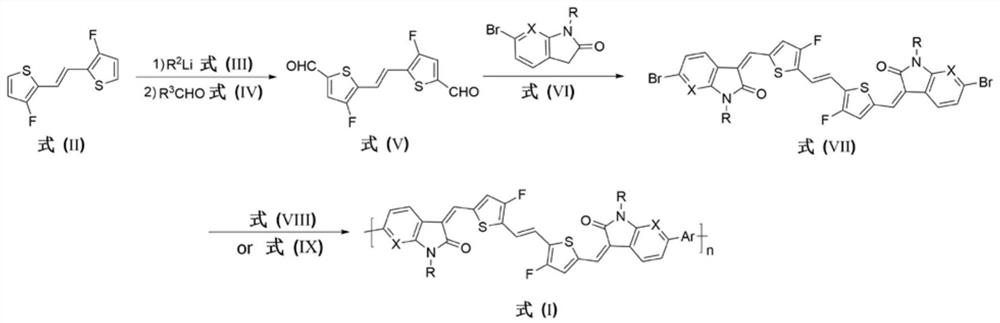

Method used

Image

Examples

Embodiment 1

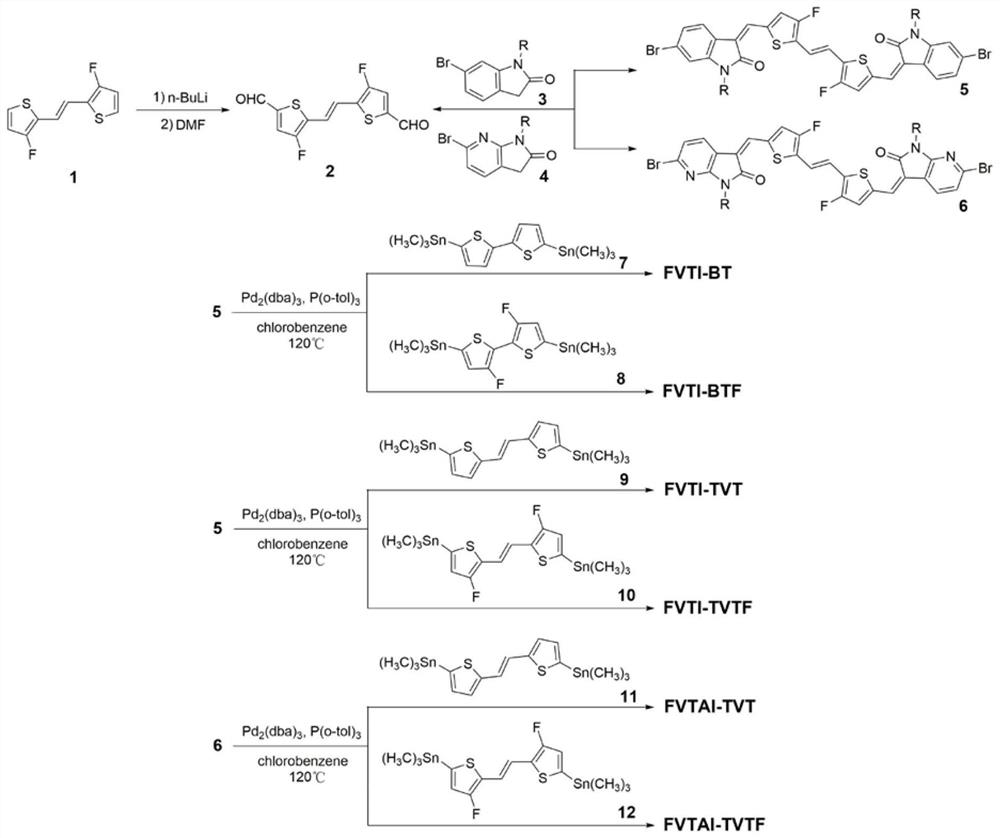

[0074] Embodiment 1, synthesis of polymer FVTI-BT (R=2-decyl dodecyl in formula I, X=C, Ar=2,2-dithiophene) (its synthetic route is as follows figure 2 shown)

[0075] 1) Synthesis of trans-1,2-bis(3-fluorothienyl)ethylene 1

[0076] To a solution of thiophene-2-carboxylic acid (17.0 g, 132.7 mmol) in anhydrous tetrahydrofuran (300 ml) was cooled to -78°C and slowly added 2.5M n-butyllithium in n-hexane (120 ml, 300 Millimoles). After completion, the reaction system was stirred at -78° C. for 30 minutes under the protection of nitrogen. Then N-fluorobisbenzenesulfonamide (50.0 g, 158.6 mmol) was dissolved in 300 ml of tetrahydrofuran and added to the reaction solution. After stirring at a low temperature of -78°C for 3 hours, hydrochloric acid was added to terminate the reaction, extracted with dichloromethane and washed with water several times, suspended in the solvent to obtain an intermediate product, and the amount of the intermediate product was accumulated by repeat...

Embodiment 2

[0103] Example 2, synthesis of polymer FVTI-BTF (R=2-decyl dodecyl in formula I, X=C, Ar=3,3-difluoro-2,2-dithiophene) (the synthesis route is as follows figure 2 shown)

[0104] The synthesis of compound 5 was carried out with reference to Example 1.

[0105] Compound 5 (265.5 mg, 0.20 mmol) and trimethyltin compound 8 (105.6 mg, 0.20 mmol), tris(dibenzylideneacetone) dipalladium (6.0 mg), tris(o-tolyl)phosphine ( 16.0 mg) and chlorobenzene (20 ml) were added into the reaction flask, and after deoxygenation at a low temperature of -78°C in nitrogen, the reaction was heated to 120°C under nitrogen protection for 15 minutes. After cooling, 200 ml of methanol / 6M HCl mixture (volume ratio 20:1) was added, stirred at room temperature for 2 hours, and filtered. The resulting solid was purified using a Soxhlet extractor. The extraction solvents were methanol, acetone, and n-hexane in sequence for 12 hours each, and then extracted with o-dichlorobenzene to obtain 258 mg of the ta...

Embodiment 3

[0109] Example 3, polymer FVTI-TVT synthesis (R=2-decyl dodecyl in formula I, X=C, Ar=trans-1,2-thienylethylene) (the synthesis route is as follows figure 2 shown)

[0110] The synthesis of compound 5 was carried out with reference to Example 1.

[0111] Compound 5 (200..0 mg 0.15 mmol) and trimethyltin compound 9 (77.7 mg, 0.15 mmol), tris(dibenzylideneacetone) dipalladium (6.0 mg), tris(o-tolyl) Phosphine (16.0 mg) and chlorobenzene (10 ml) were added to the reaction flask, and after deoxygenation at a low temperature of -78°C in nitrogen, the reaction was heated to 120°C under nitrogen protection for 15 minutes. After cooling, 200 ml of methanol / 6M HCl mixture (volume ratio 20:1) was added, stirred at room temperature for 2 hours, and filtered. The resulting solid was purified using a Soxhlet extractor. The extraction solvents were methanol, acetone, and n-hexane in sequence for 12 hours each, and then extracted with o-dichlorobenzene to obtain 196 mg of the target poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com