Methods for improving the energy dissipation capacity of precast segmental assembled piers

A segmental and pier technology, which is applied in the field of improving the energy dissipation capacity of prefabricated segmental assembled bridge piers under earthquake action, and can solve the problems of increased design complexity and construction difficulty of prefabricated segmental assembled bridge piers, unclear force transmission paths, and changes in bridge pier stiffness And other problems, to achieve the effect of reliable performance, wide application range, convenient maintenance and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with example and accompanying drawing, the present invention will be further described.

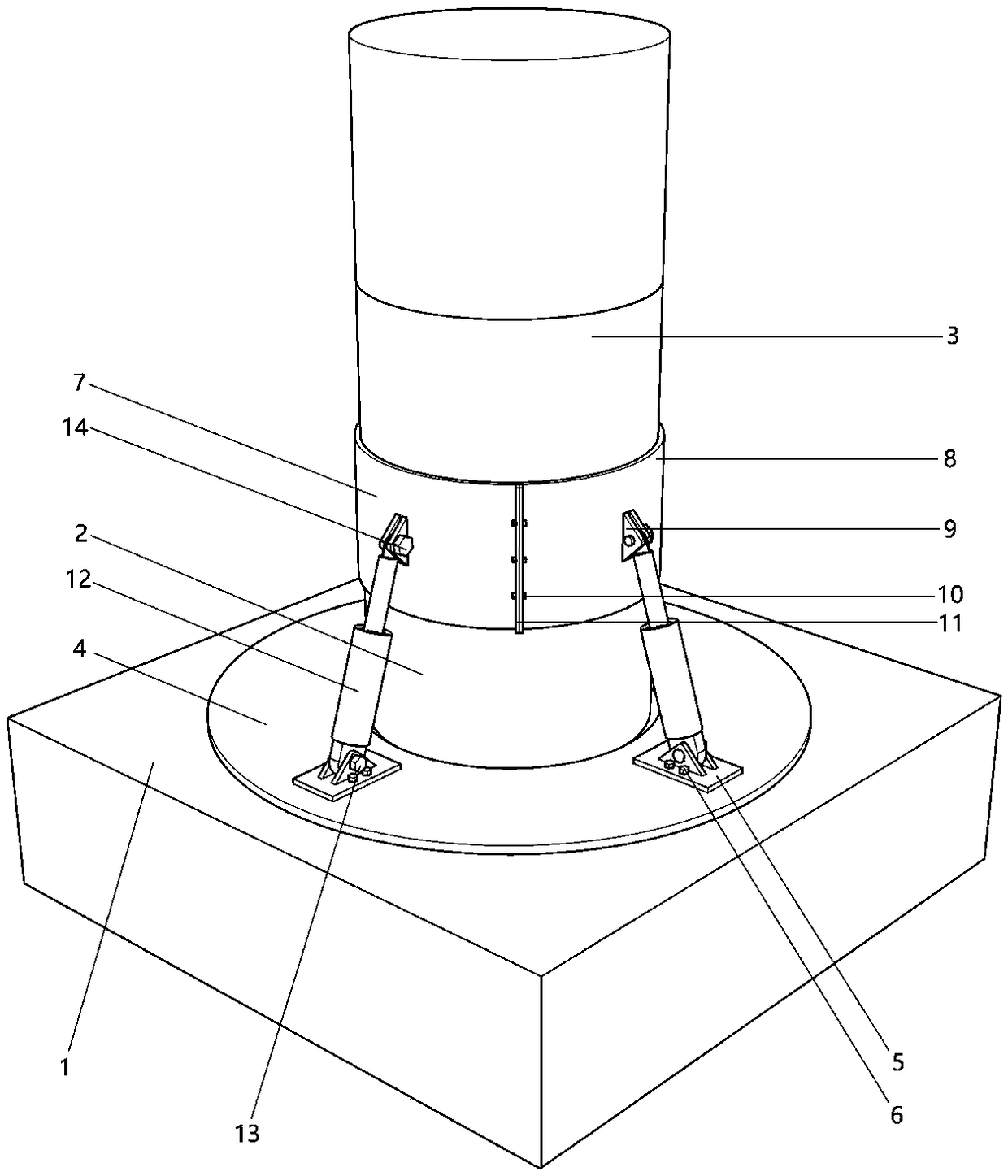

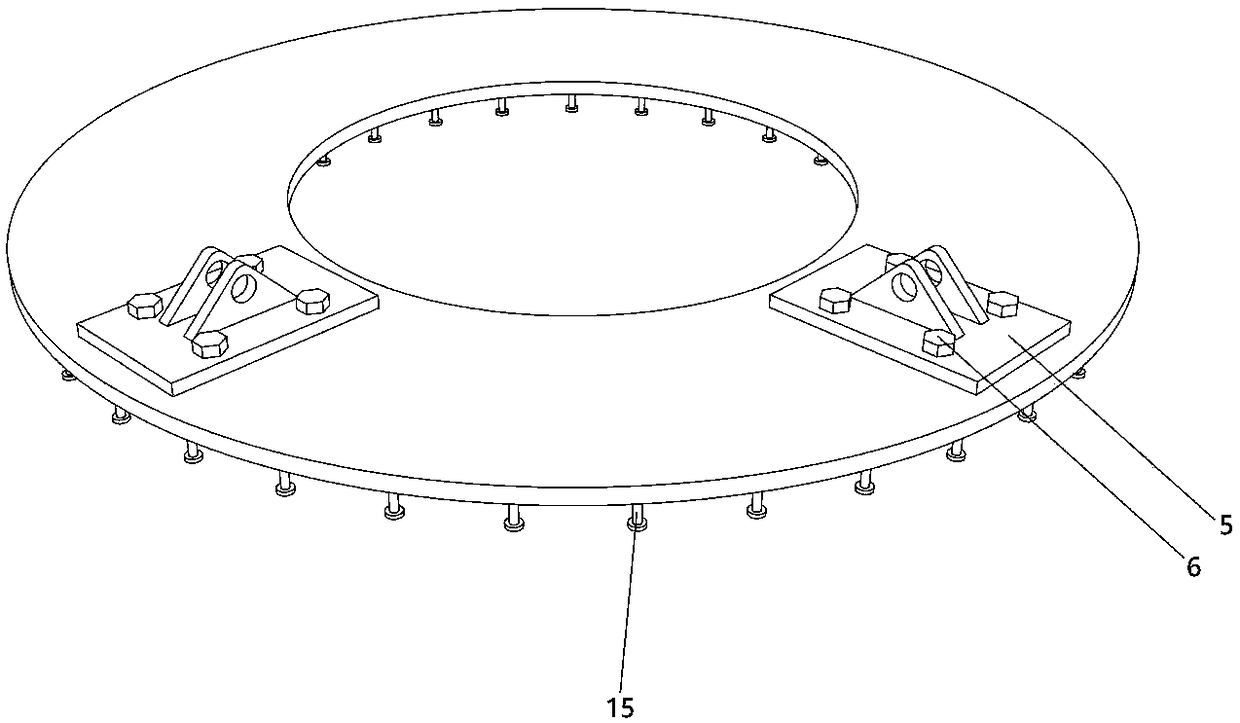

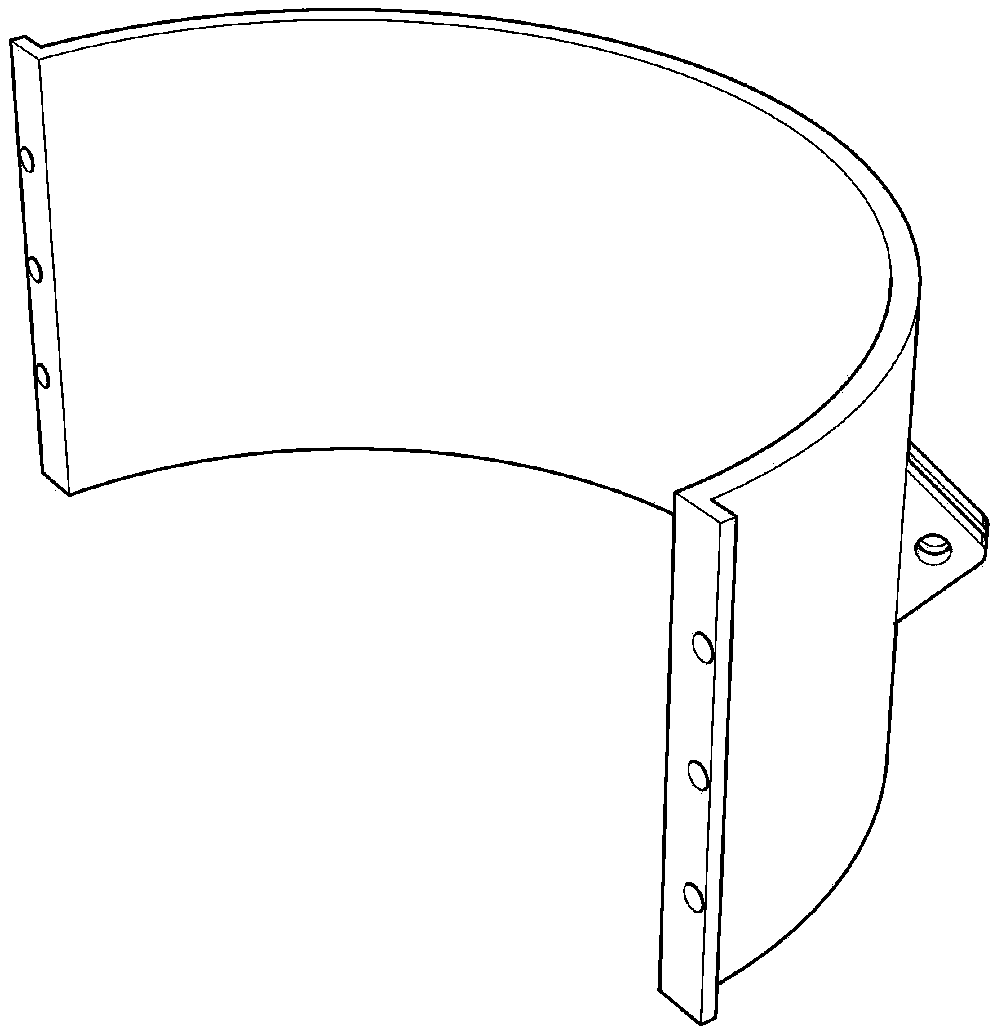

[0028] The invention provides a method for improving the energy consumption capacity of prefabricated segmental assembled bridge piers. like figure 1 As shown, it is mainly composed of prefabricated segmental assembled pier, viscous fluid damper 12, steel sleeve assembly 7-8 with damper top support 9 and annular steel plate base 4 with damper bottom support 5. The ring-shaped steel plate 4 with the bottom support 5 of the damper is evenly welded with N rings of studs 15 along the perimeter, and the ring-shaped steel plate 4 is installed on the top surface of the bearing platform 1; after the pier body segment is assembled, the The steel sleeve assembly 7 8 with the top support 9 of the damper is installed at the joint position of the bottom section 2 of the pier body and the second section 3 at the bottom, and the locking plate 11 is locked with bolts 10; afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com