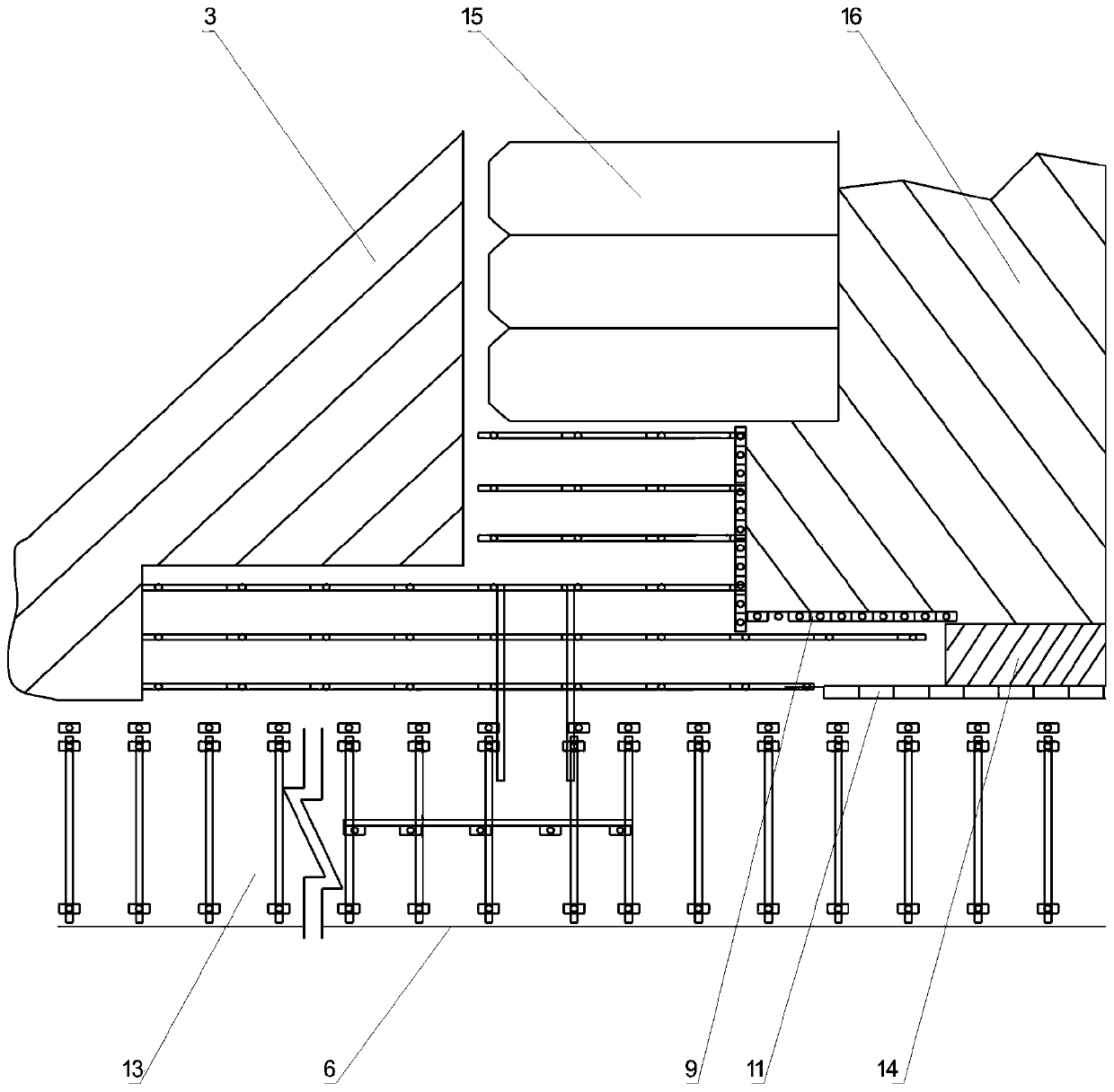

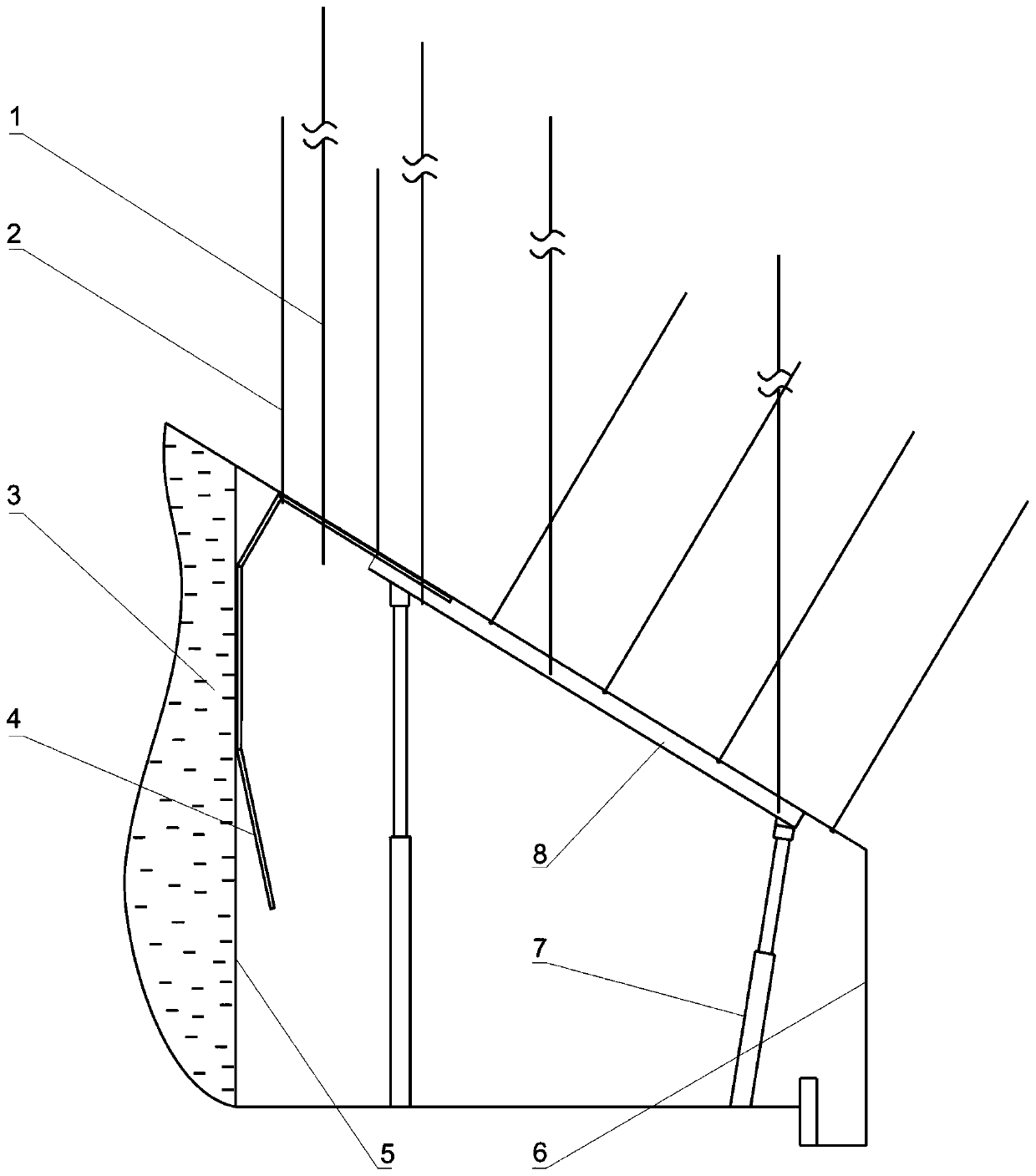

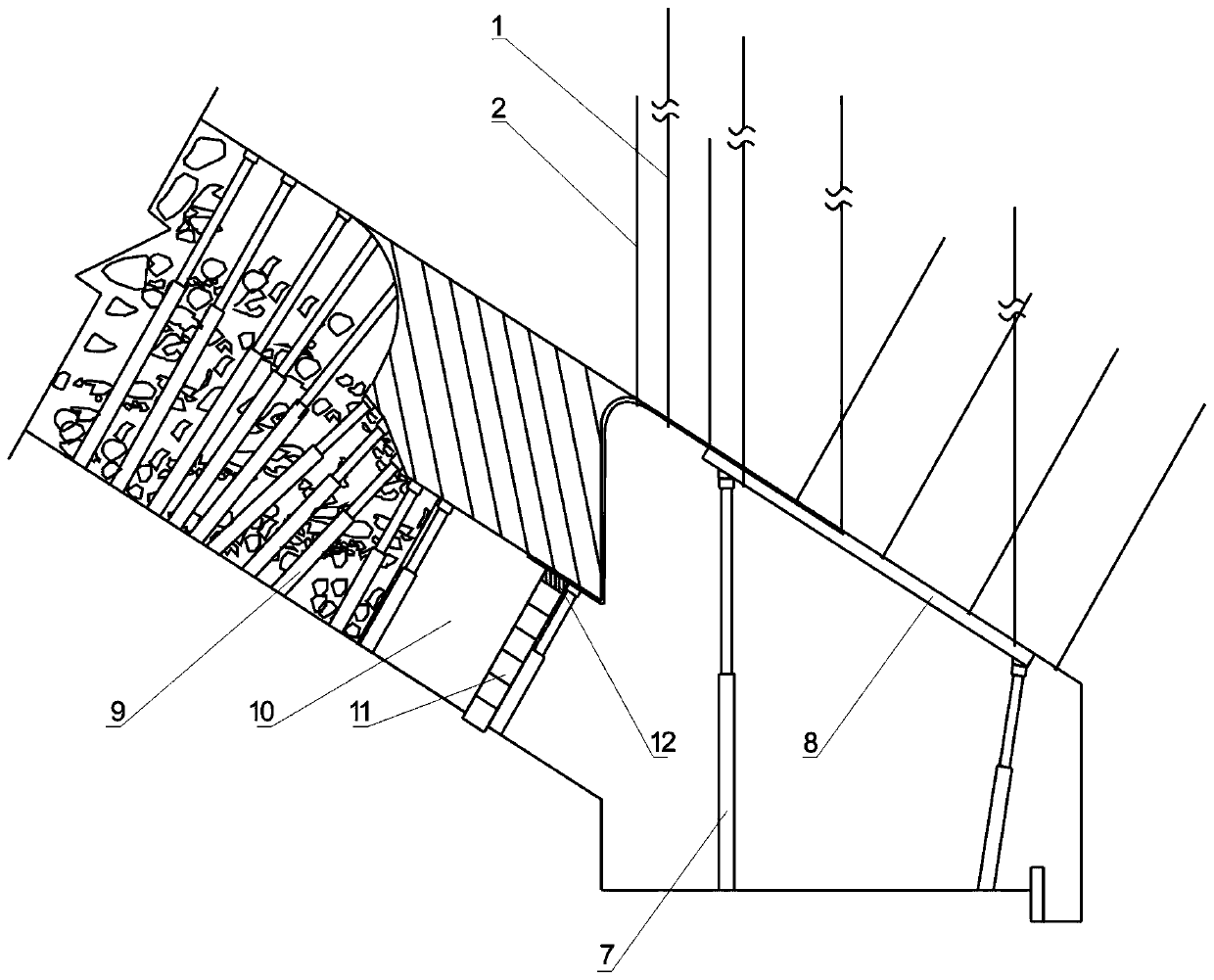

Combined gob-side entry retaining method of wedge-shaped regenerated wall and single-leg shed beam in coal mining roadway

A technology for empty entry and roadway, which is used in tunnels, ground mining, mining equipment and other directions to achieve the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0044] The mechanically transported roadway tested by the present invention will be used as the return air roadway of the coal mining face in the lower section after the roadway is successfully retained. Namely the roadway 13 described in the present invention.

[0045] The basic conditions of its coal mining face 3 and roadway 13 are as follows.

[0046] This coal mining face machine roadway (roadway described in the present invention) is gob-side retaining roadway, does not establish roadway retaining coal pillar, is mining without coal pillar. The coal seam has a monocline structural strike of 315°, the maximum dip angle of the coal seam is 34°, the minimum is 27°, and the average is 31°. The maximum thickness of the coal seam is 2.9m, the minimum is 1.63m, the average thickness is 2.3m, the average mining height is 2.7m, the average thickness of the direct roof is 1.96m, and the bulk density (t / m 3 )1.35, the average inclination length of the coal mining face is 130m, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com