Integrated cooker with smoke backflow protection devices and manufacturing method thereof

An anti-backflow device and integrated stove technology, applied in the field of integrated stoves, can solve the problems of affecting the kitchen operating environment, secondary pollution of the kitchen environment, general smoking effect, etc., to reduce noise pollution, the overall structure is compact and reasonable, and the overall structure design is ingenious reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

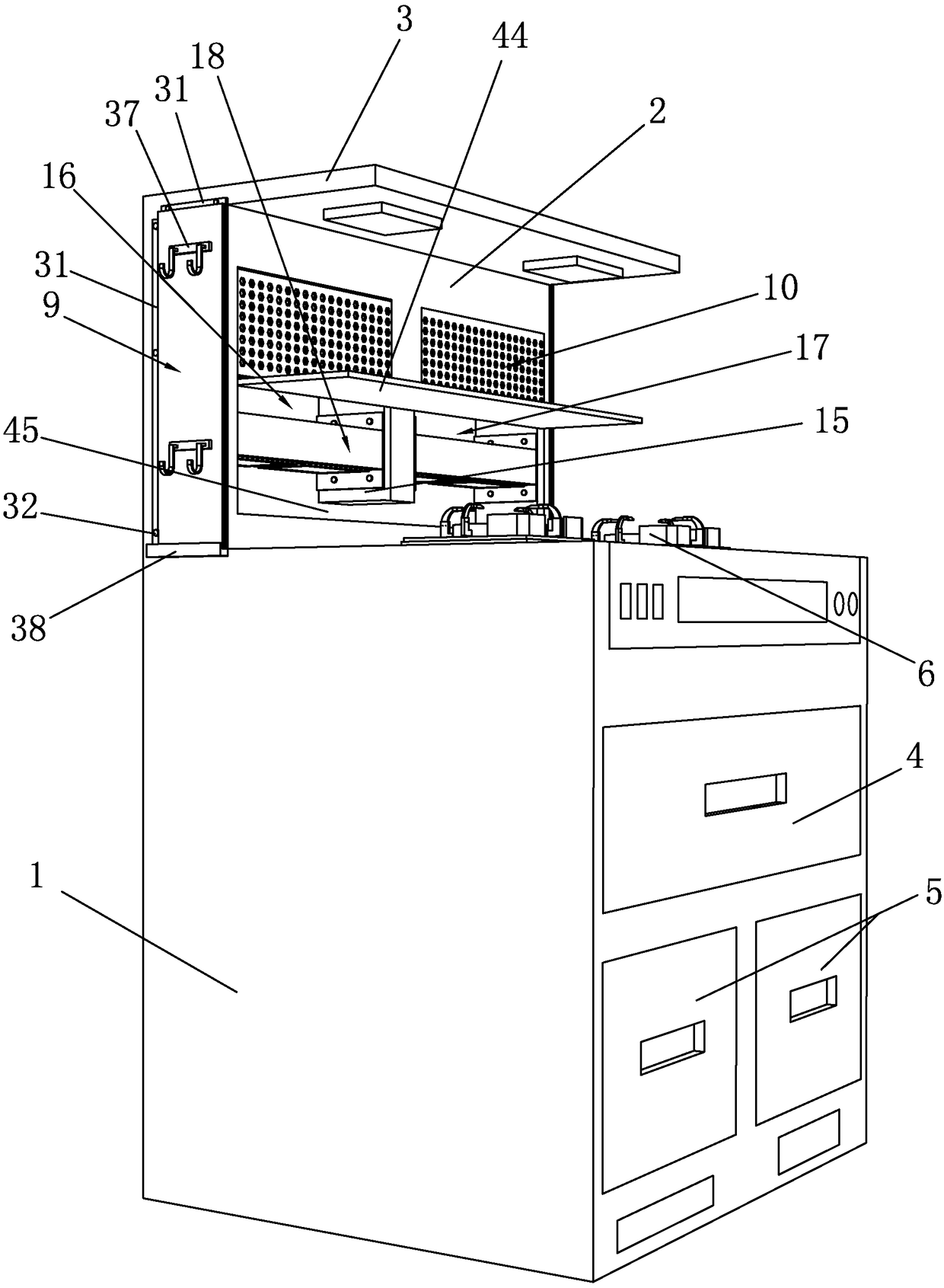

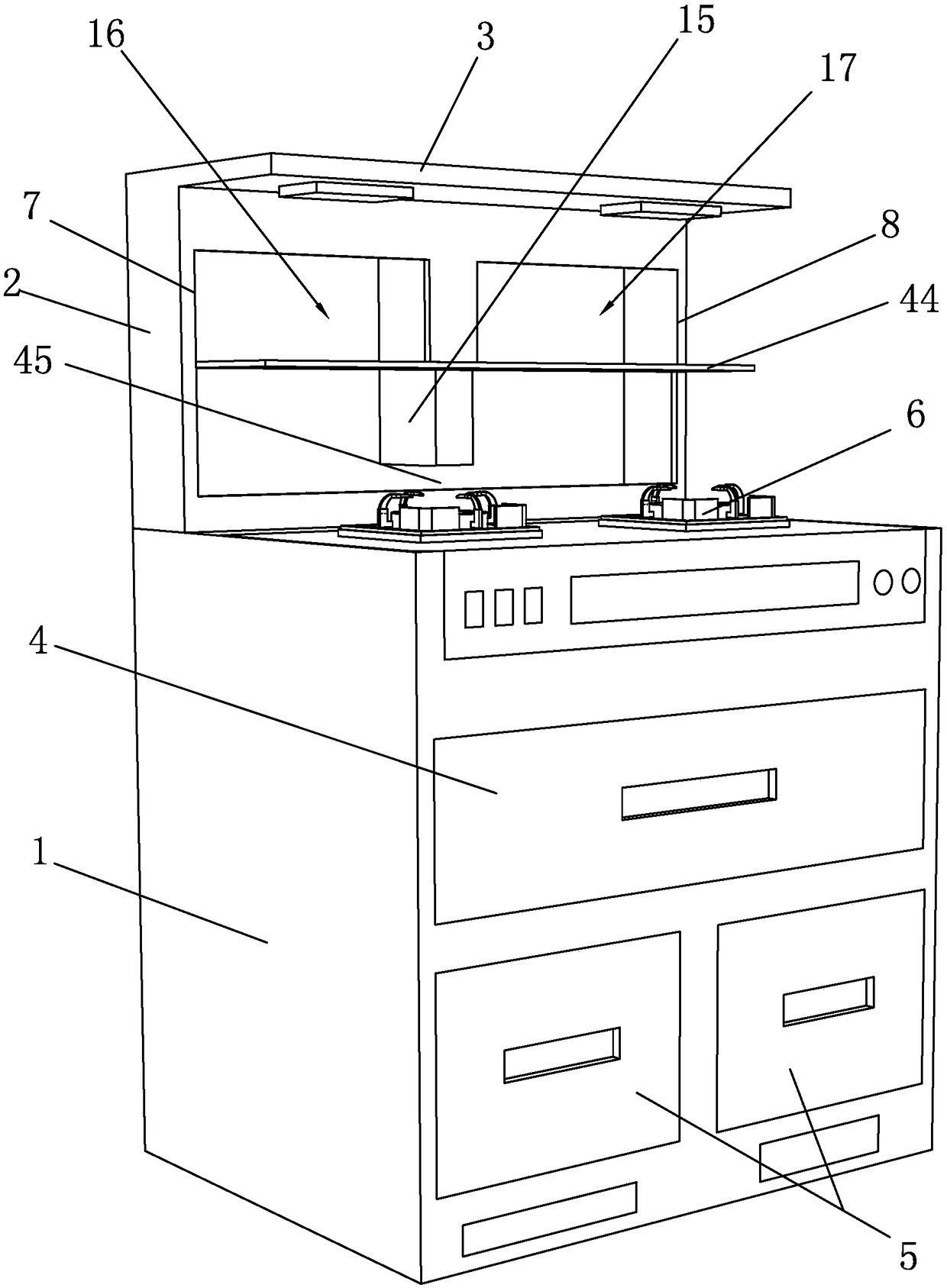

[0053] Such as Figure 1 to Figure 8 As shown, it is an integrated stove with a flue gas backflow prevention device according to the present invention, which includes a body 1, a side plate 2 and a smoke baffle 3, a disinfection cabinet 4 and a locker 5 are arranged on the front end of the body 1, and the body 1 Two stove stands are arranged on the top surface of the body, the side plate 2 is located above the body 1, and the smoke shield 3 is located on the top surface of the side plate 2.

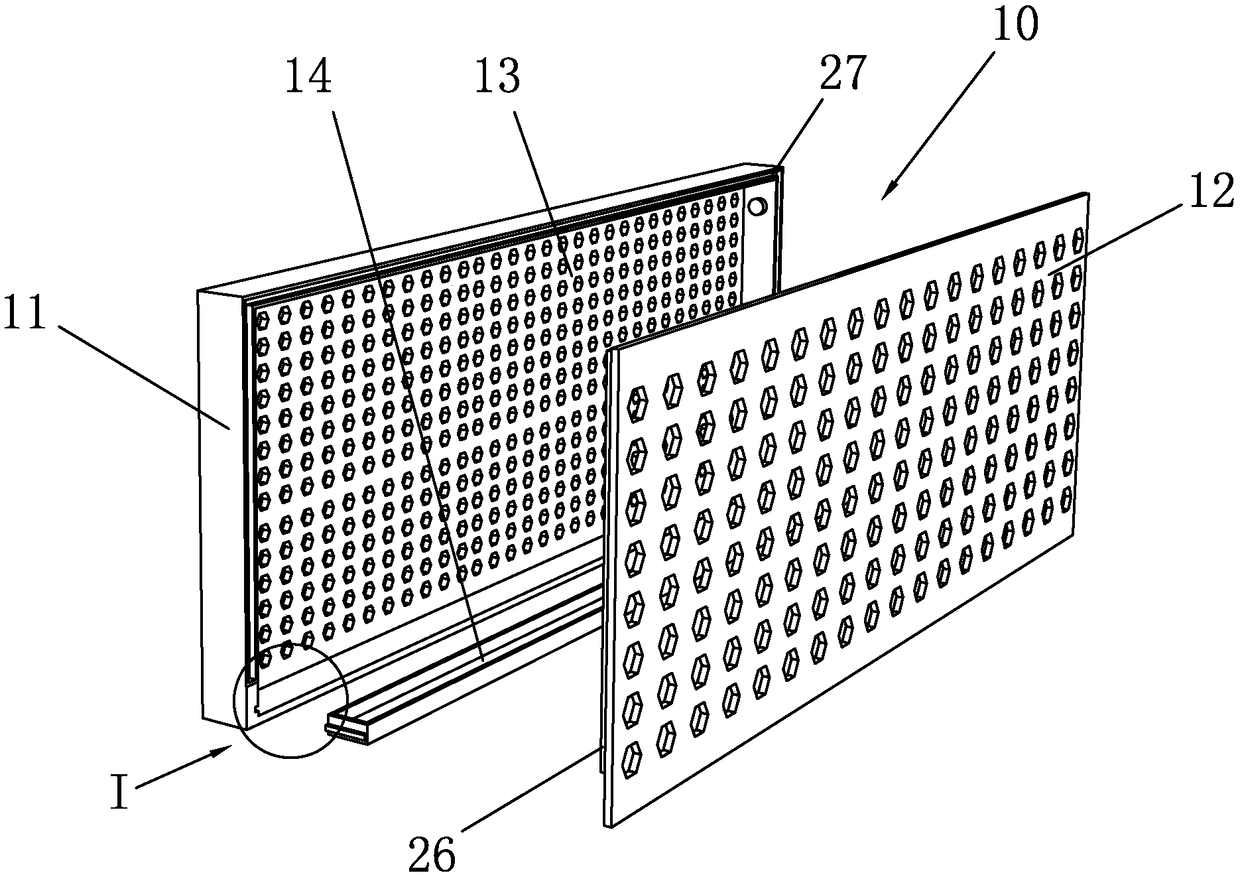

[0054]Both sides of the side plate 2 are provided with a baffle assembly 9, the baffle assembly 9 includes a first baffle 28, a second baffle 29 and a third baffle 30, the first baffle 28 is provided with an extension block 31, extending The block 31 and the first baffle 28 are integrally formed, and the extension block 31 is fixedly connected with the side plate 2 through the fixing screw 32. A first slide block 34 matching the first chute 33 is provided on the rear end surface, the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com