A multi-manifold air supply fuel cell system and method

A fuel cell system and air supply technology, which is applied in the direction of fuel cells, circuits, electrical components, etc., can solve the problems of large influence on the consistency of the stack, high local current density, inconsistent paths, etc., so as to avoid local excessive or excessive Low, improve the degree of inconsistency, reduce the effect of air pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

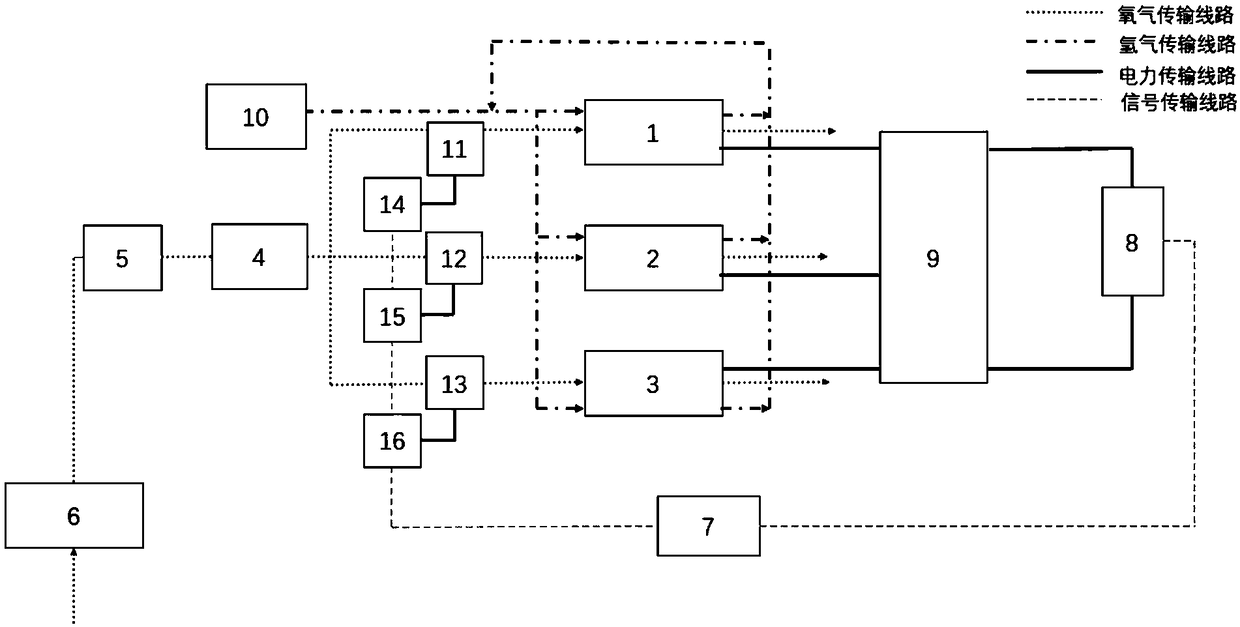

[0041] A fuel cell system fueled by multi-manifold air supply, including the following structure: an air compressor 6 that presses ambient air into it at high speed; a humidifier 5 arranged behind the air compressor 6; It is the intake main pipeline of the multi-manifold 4, and each branch manifold of the multi-manifold includes a throttle valve 11, a throttle valve 12 and a throttle valve 13, and the outlet pipe of the multi-manifold 4 is connected with each cathode end of the fuel cell; the fuel cell system It consists of a battery stack module 1, a battery stack module 2 and a battery stack module 3 in the form of a stack module; the hydrogen supply pipeline of the hydrogen storage device 10 is connected to each anode terminal of the fuel cell; one end of the electric energy conversion device 9 is connected to the fuel cell, The other end is connected to the load 8; one end of each servo motor 14, 15, 16 is connected to the throttle valve 11, 12, 13 respectively, and the oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com