Control circuit of high-efficient induction heating quenching machine tool

A control circuit and induction heating technology, applied in the direction of quenching device, digital control, energy efficiency improvement, etc., to achieve the effect of compact structure, high reliability and high efficiency of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

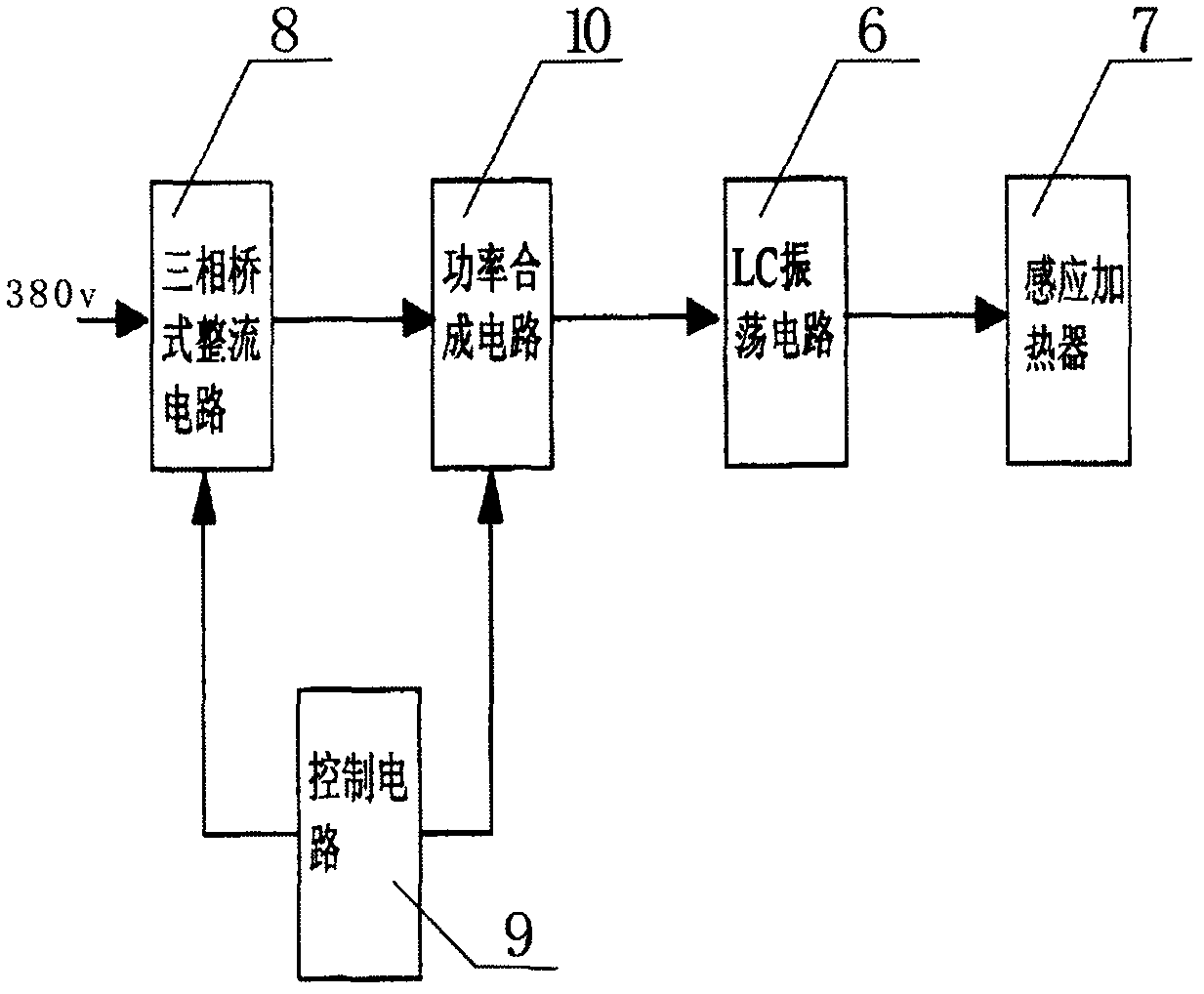

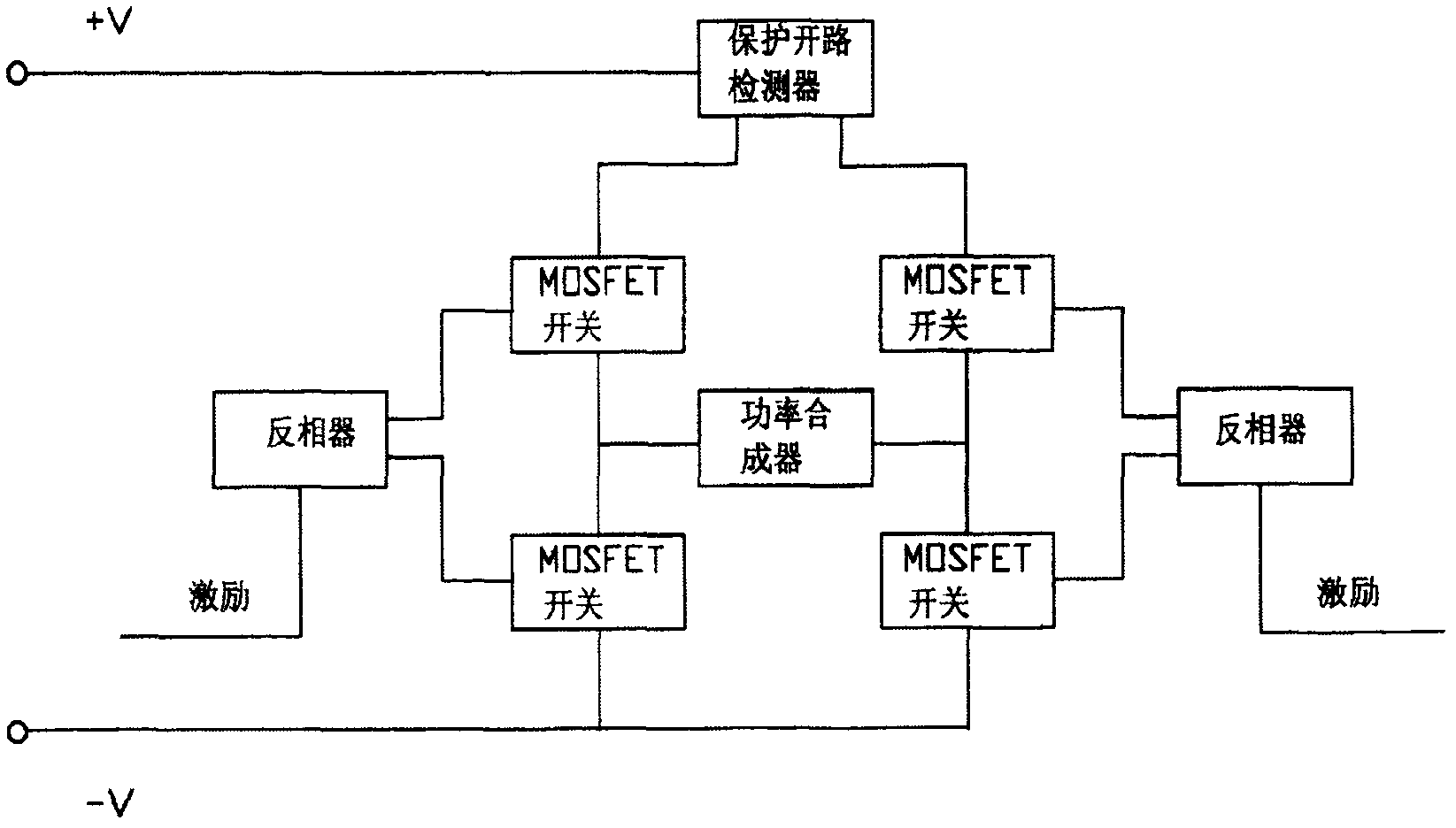

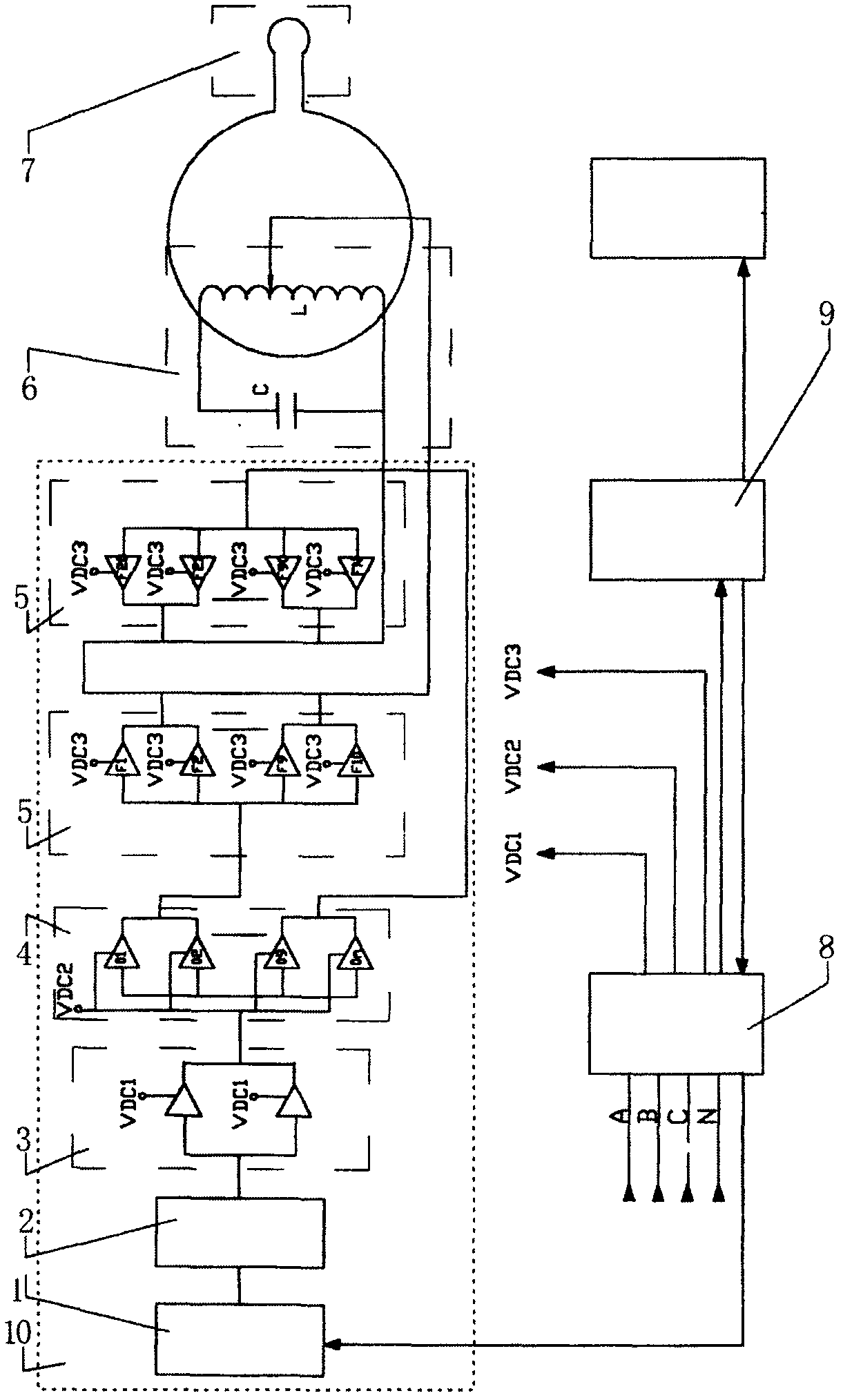

[0015] Such as figure 1 , 3 As shown, the control circuit of the high-efficiency induction heating and quenching machine tool includes 380V AC power supply, three-phase bridge rectifier circuit module 8, control circuit module 9, power synthesis circuit module 10, LC oscillation circuit module 6 and induction heater 7. 380V AC After the power supply passes through the three-phase bridge rectifier circuit module 8, the distribution network supplies power to the pre-driver stage 3, the driver stage 4, and the power amplifier stage 5 respectively, and simultaneously supplies power to the frequency control circuit in the control circuit module 9 and the power synthesis circuit module 10 Module 1 provides power, and frequency control circuit 1 connects the output of the frequency signal required for the operation of the equipment to the input of buffer stage 2, and buffer stage 2 connects the output of the adjusted frequency signal power to the power module units in pre-driver stag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com