Copper wire stripping device

A copper wire and paint stripping technology, which is applied in the direction of electromechanical devices, cable installation devices, cable installation, etc., can solve the problems of difficult clamping and fixing of copper wires, inconvenient removal of paint skin, poor overall effect, etc., and achieve better paint stripping effect Good, perfect overall function, strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

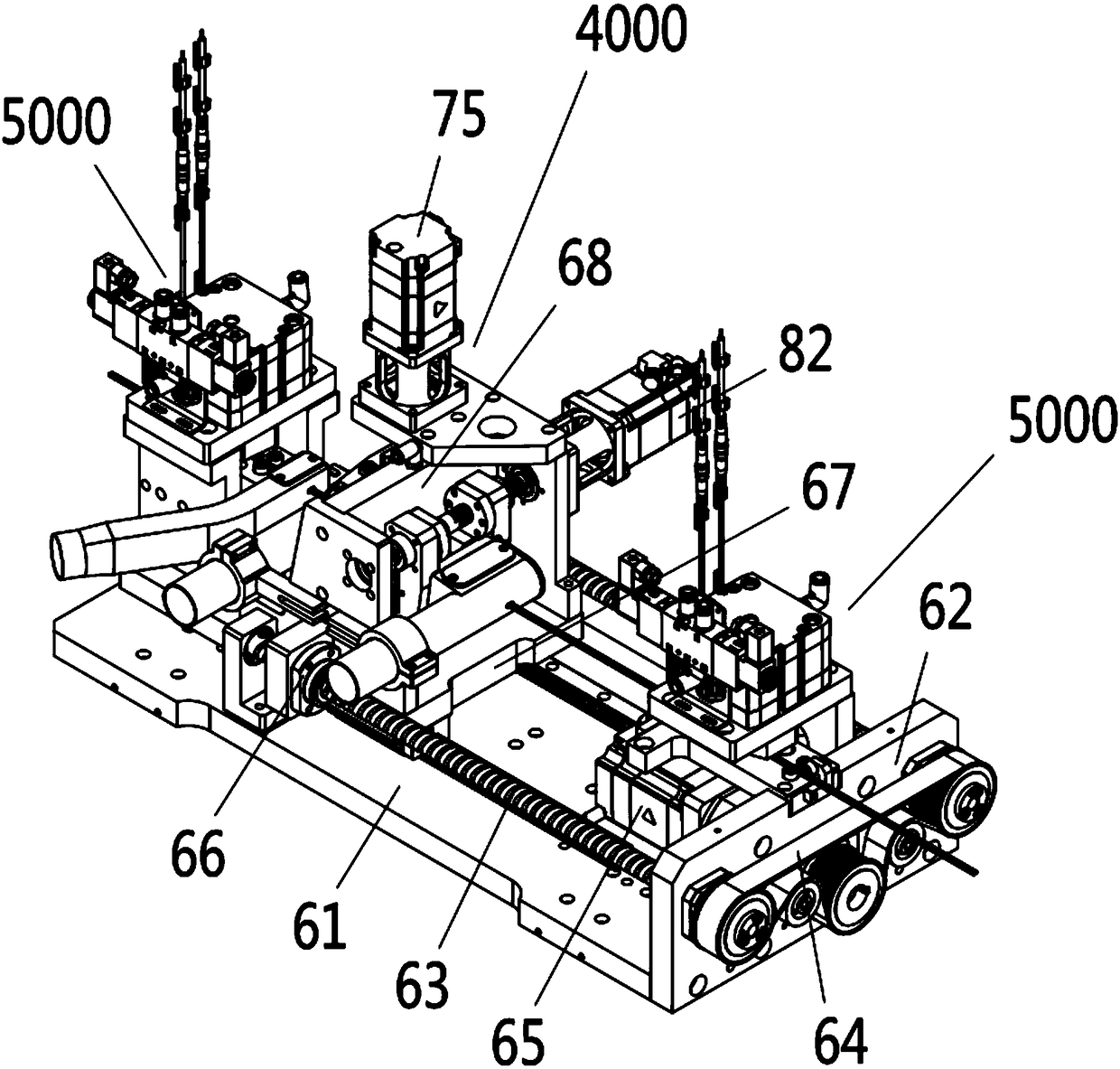

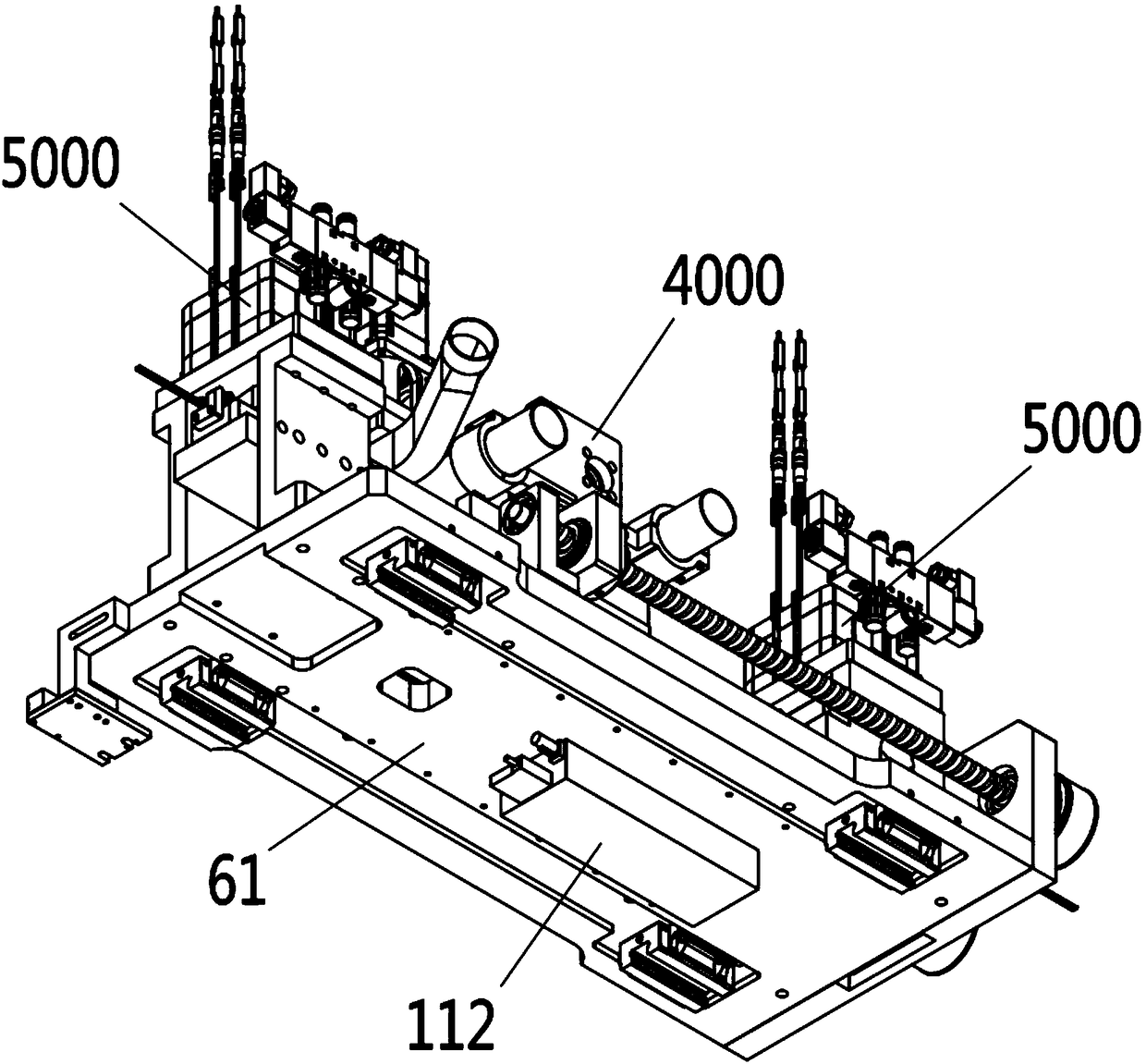

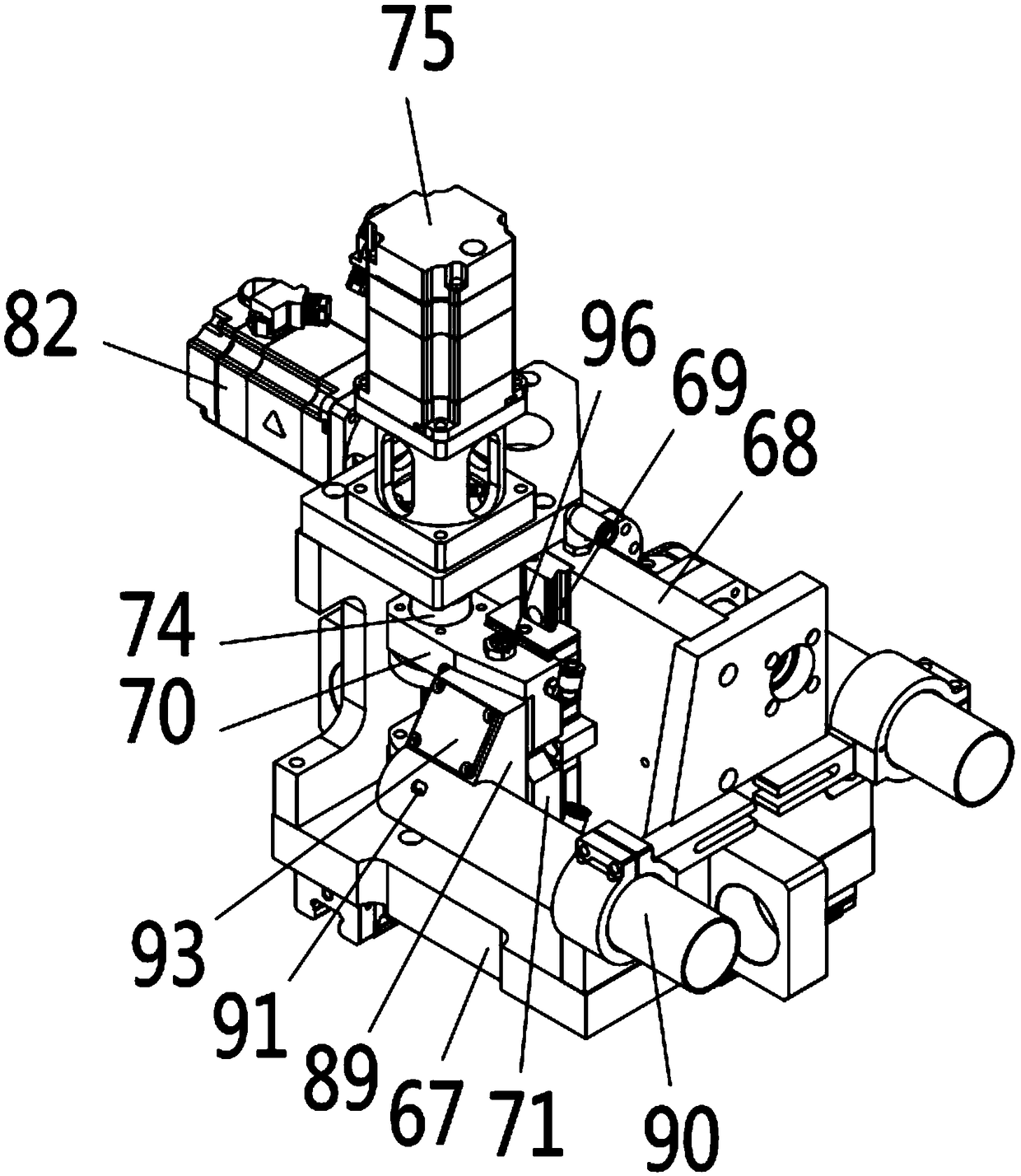

[0037] see Figures 1 to 2As shown, a copper wire paint stripping device involved in this embodiment includes a base plate 2 61, a linear motor 112 is provided on the bottom surface of the base plate 2 61, a scraper mechanism 4000 is provided on the top surface of the base plate 2 61, and the scraper mechanism 4000 A pressing mechanism 5000 is respectively provided on both sides. The second base plate 61 can be used to be installed on the assembly line, and the linear motor 112 drives the second base plate 61 to make a linear motion on the assembly line; the pressing mechanism 5000 is used to compress and fix the conveyed copper wire, and two sections of copper wire in the process of conveying are pressed and fixed. The two ends of the pressing mechanism 5000 are pressed together, and the pressing mechanism 5000 continues to move forward with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com