Adsorbent for treatment of dye wastewater and printing-dyeing wastewater and preparation method thereof

A printing and dyeing wastewater and adsorbent technology, which is applied in the textile industry wastewater treatment, water/sewage treatment, adsorbed water/sewage treatment and other directions, can solve the problems of weak adsorption of organic pollutants and cannot be removed efficiently at the same time, to avoid The effect of solid waste generation and high adsorption and removal capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

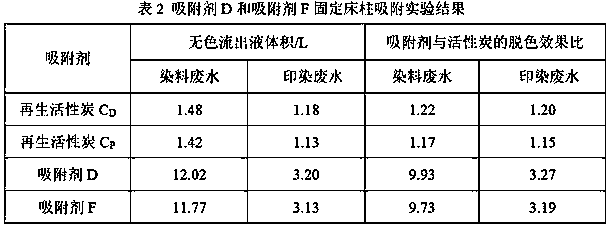

Embodiment 1

[0014] Weigh 50 grams of powdered activated carbon that has been crushed and passed through an 80-mesh sieve, and then weigh 50 grams of cross-linked cationic starch that has been crushed and passed through an 80-mesh sieve. Adsorbent A.

Embodiment 2

[0016] Weigh 50 grams of powdered activated carbon that has been crushed and passed through a 120-mesh sieve, and then weigh 50 grams of cross-linked cationic polyvinyl alcohol that has been crushed and passed through a 120-mesh sieve. Adsorbent B.

Embodiment 3

[0018] Take by weighing 40 grams of powdered activated carbon that has been crushed and crossed an 80 mesh sieve, then weigh 30 grams of cross-linked cationic starch that has been crushed and crossed an 80 mesh sieve and 30 grams of cross-linked cationic polyvinyl alcohol that has been crushed and crossed an 80 mesh sieve , after fully mixing the three, a kind of adsorbent C for printing and dyeing wastewater treatment is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com