High space velocity sulfur resistant pre-shift catalyst and preparation method thereof

A catalyst and pre-conversion technology, applied in the direction of chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the effects of catalyst activity and activity stability, internal active components Decreased utilization rate, large influence of internal diffusion, etc., to achieve the effects of strong adsorption and removal of poisons, good conversion activity and activity stability, and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

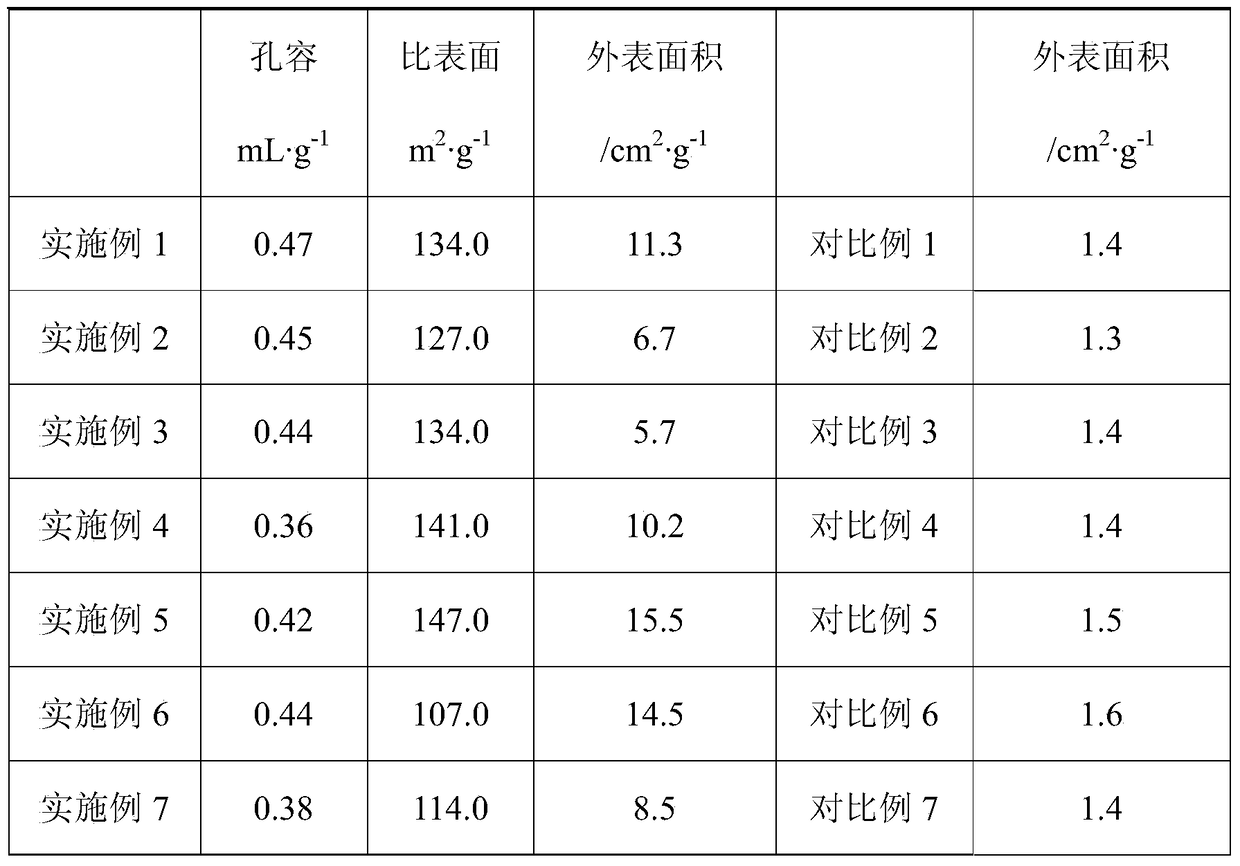

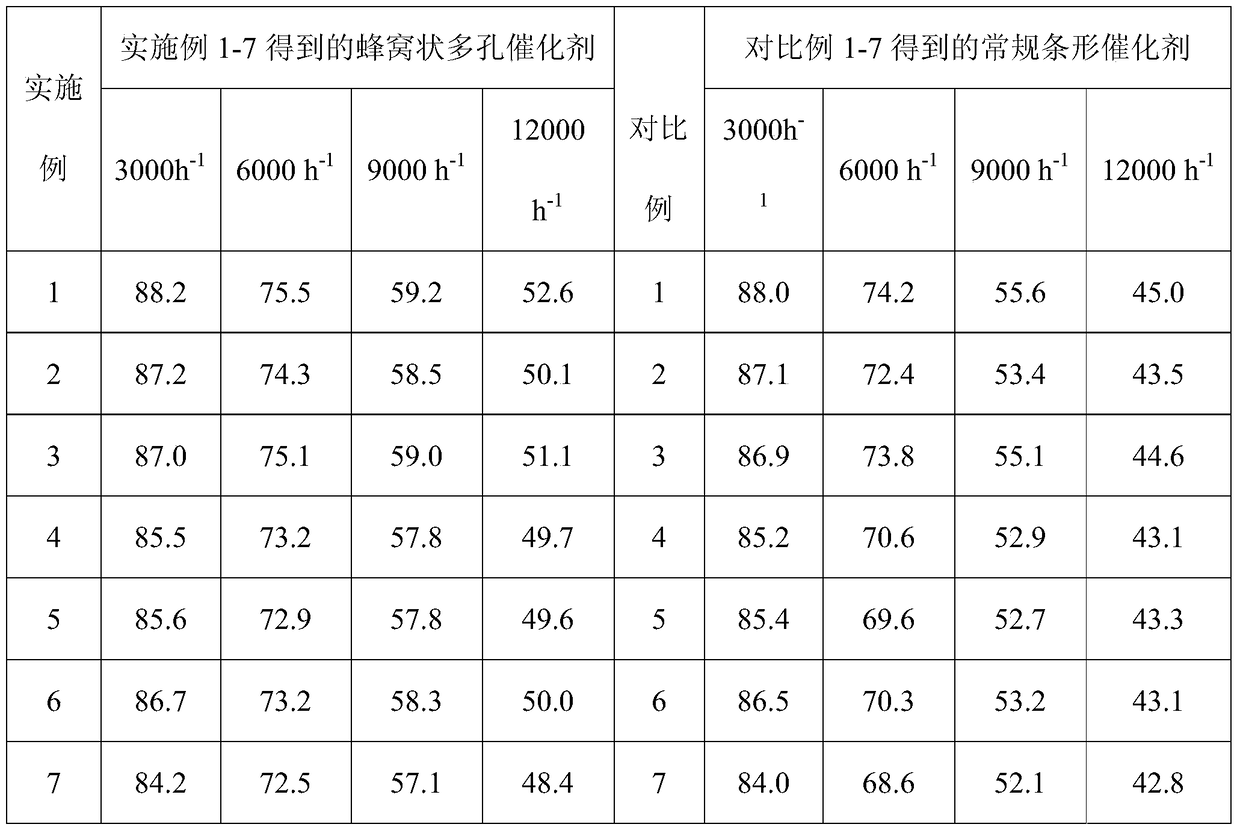

Examples

Embodiment 1

[0038] Dissolve 5.63 g of ammonium molybdate in 20 ml of deionized water, and adjust the pH to 7.5 with ethylenediamine to obtain solution A. Solution B was obtained by dissolving 7.90 g of nickel nitrate and 7.77 g of cobalt nitrate in 25 ml of deionized water. Then 3 g of citric acid and 4.3 g of metatungstic acid were dissolved in 10 ml of deionized water to obtain solution C. Mix 93g of pseudo-boehmite, 16.5g of light magnesium oxide, 14.3g of metatitanic acid, and 3g of Tianqing powder, add solution C, and knead evenly; use a 20-hole die to extrude into a honeycomb-like carrier, and dry naturally And 500 ℃ calcined to prepare the catalyst carrier. Put the calcined catalyst carrier in a weakly acidic solution adjusted to PH=6.5 with citric acid and oxalic acid, soak it at 40°C for 4 hours, take it out, dry it at 70°C for 2 hours, and then dry it at 220°C for 2 hours to get pretreated carrier; put the pretreated catalyst carrier into solution B for equal-volume impregnati...

Embodiment 2

[0049] Dissolve 5.63 g of ammonium molybdate with 15 ml of deionized water, and adjust the pH to 7.1 with triethanolamine to obtain solution A. Solution B was obtained by dissolving 1.95 g of nickel nitrate and 11.65 g of cobalt nitrate in 30 ml of deionized water. Then 2 g of acetic acid and 5.4 g of magnesium acetate were dissolved in 10 ml of deionized water to obtain solution C. Mix 60g of alumina, 20g of light magnesia, 12g of titanium oxide, 1g of sucrose and 2g of starch evenly, add solution C, and knead evenly; use a 16-hole die to extrude into a honeycomb-like carrier, naturally dry and roast at 450°C Then the catalyst carrier is prepared. Place the calcined catalyst carrier in a weakly acidic solution adjusted to PH=5.5 with citric acid, soak it at 35°C for 3 hours, take it out, dry it at 70°C for 2 hours, and then dry it at 220°C for 1 hour to get the pretreated carrier Put the pretreated catalyst carrier into solution B for equal volume impregnation for 2 hours, ...

Embodiment 3

[0051] 6.2 g of ammonium molybdate was dissolved in 20 ml of deionized water, and the pH was adjusted to 7.6 with propanolamine to obtain solution A. Solution B was obtained by dissolving 7.90 g of nickel nitrate and 3.9 g of cobalt nitrate in 25 ml of deionized water. Then 2 g of oxalic acid, 2 g of citric acid and 6.07 g of copper nitrate were dissolved in 15 ml of deionized water to form solution C. Mix 100g of aluminum glue, 27g of heavy magnesium oxide, 22g of metatitanic acid, and 4g of polyvinyl alcohol evenly, add solution C, and knead evenly; use a 14-hole die to extrude into a honeycomb-like carrier, naturally dry and bake at 600°C Then the catalyst carrier is prepared. Put the calcined catalyst carrier in a weakly acidic solution adjusted to PH=6.8 with oxalic acid and acetic acid, soak it at 30°C for 10 hours, take it out, dry it at 70°C for 5 hours, and then dry it at 220°C for 1 hour to get the pretreated Carrier: Put the pretreated catalyst carrier into soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com