Boat pushing reducing furnace device and gas supply method

A reduction furnace and furnace tube technology, which is applied in the field of powder metallurgy, can solve the problems that hydrogen cannot enter the recovery system, the operation of the recovery system is interrupted, and the size of the furnace tube is large, so as to reduce safety hazards, reduce overflow loss, and improve utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

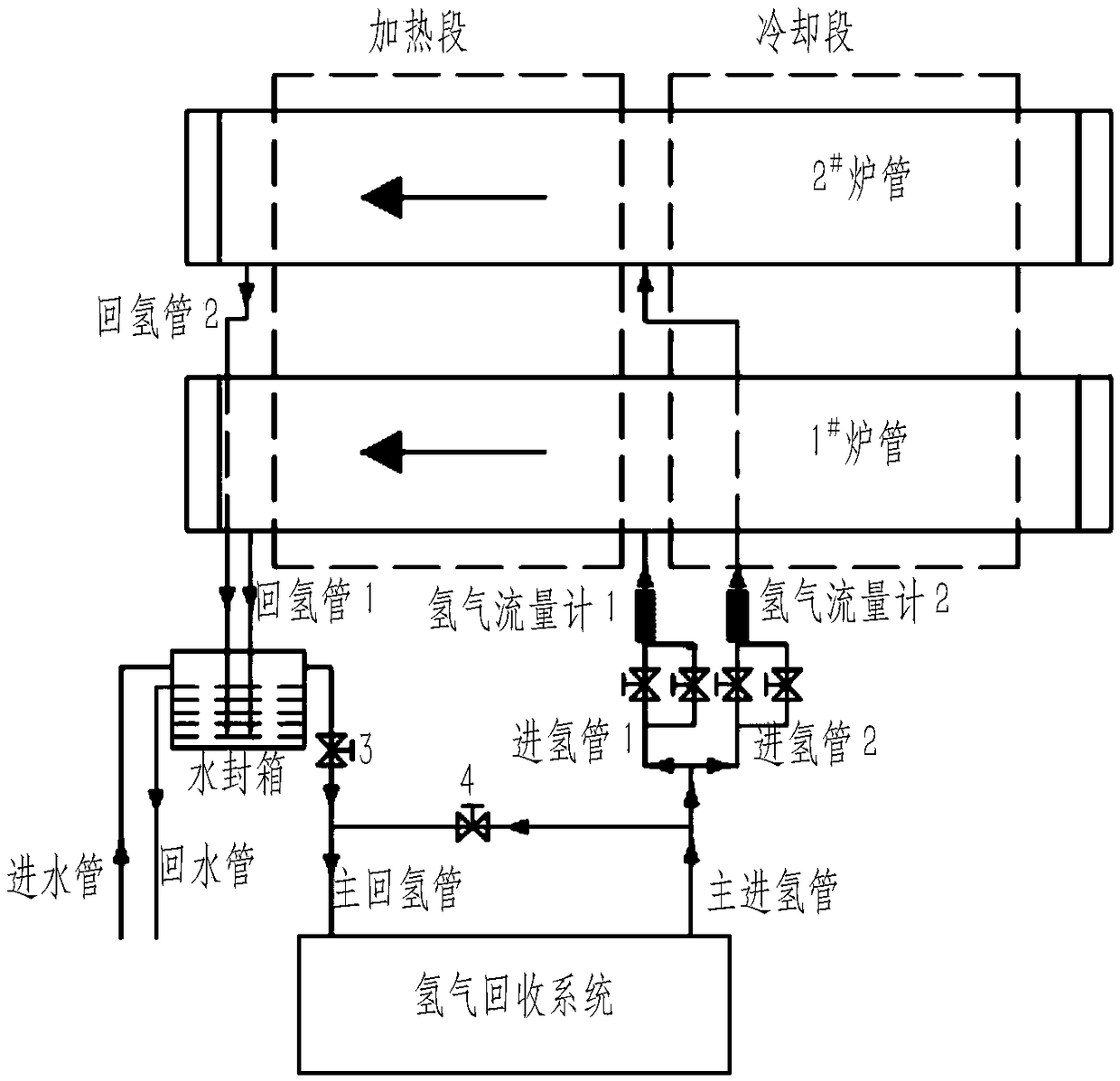

[0024] A specific embodiment of the present invention, such as figure 1 As shown, the reduction furnace is a double-tube pusher reduction furnace for production, including furnace tubes, hydrogen inlet pipelines, hydrogen return pipelines and water-sealed boxes. Furnace tube includes 1 # furnace tube and 2 # The furnace tube, the hydrogen inlet pipeline includes the main hydrogen inlet pipe, the hydrogen inlet pipe 1 and the hydrogen inlet pipe 2, the hydrogen return pipeline includes the main hydrogen return pipe, the hydrogen return pipe 1 and the hydrogen return pipe 2, and the water seal box is equipped with Water pipes and return pipes. The hydrogen inlet pipe 1 is provided with a solenoid valve 1-1 and a bypass valve 1-2, and the hydrogen inlet pipe 2 is provided with a solenoid valve 2-1 and a bypass valve 2-2. The solenoid valve is a kind of program control valve, and the bypass valve The valve is a normally open valve. A solenoid valve 3 is provided on the main hy...

Embodiment 2

[0027] The hydrogen in the hydrogen storage tank (tank D) enters the furnace tube through the hydrogen inlet pipeline, and the oxidized metal powder is reduced in the furnace tube, then the hydrogen passes through the water-sealed box, and enters the hydrogen recovery system through the main hydrogen return pipe.

[0028] Gas supply method 1 for the push boat reduction furnace: When the reduction furnace is not in operation, that is, when the furnace door is closed, the leakage of hydrogen gas is very small and can be ignored due to the good sealing of the push boat reduction furnace. Except for a small part of the hydrogen consumption (about 10%), most of the hydrogen enters the hydrogen recovery system through the hydrogen return pipeline.

[0029] When 1 # furnace tube and 2 # When the furnace doors of the furnace tube are all closed, the solenoid valve 1-1, the solenoid valve 2-1 and the solenoid valve 3 are all in the open state, the solenoid valve 4 is in the closed sta...

Embodiment 3

[0031] The second method of gas supply to the push boat reduction furnace: When 1 # furnace tube or 2 # When one of the furnace doors of the furnace tube is opened to feed materials, the corresponding solenoid valve 1-1 or solenoid valve 2-1 is automatically closed, solenoid valve 3 is open, solenoid valve 4 is closed, bypass valve 1-2 and bypass valve The through valve 2-2 is a normally open valve; when the furnace door is closed, the corresponding solenoid valve is automatically opened.

[0032] When 1 # When the furnace tube is opened and fed, hydrogen overflows, then 1 # The pressure difference between the pressure at the inlet of the furnace tube and the atmosphere is almost zero, which makes 1 # The hydrogen in the furnace tube cannot enter the main hydrogen return pipe through the water seal. At this time, the solenoid valve 1-1 is automatically closed, and the hydrogen only passes through the bypass valve 1-2 at a distance of 5m. 3A small flow rate of / h flows into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com