Pump and valve coordinated control method used for prestress intelligent tensioning device

A technology of intelligent tensioning and cooperative control, applied in mechanical equipment, fluid pressure actuation devices, fluid pressure actuation system testing, etc., can solve the problem of low load stiffness, low control precision, and complex structure of electro-hydraulic servo valves in pump control systems And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

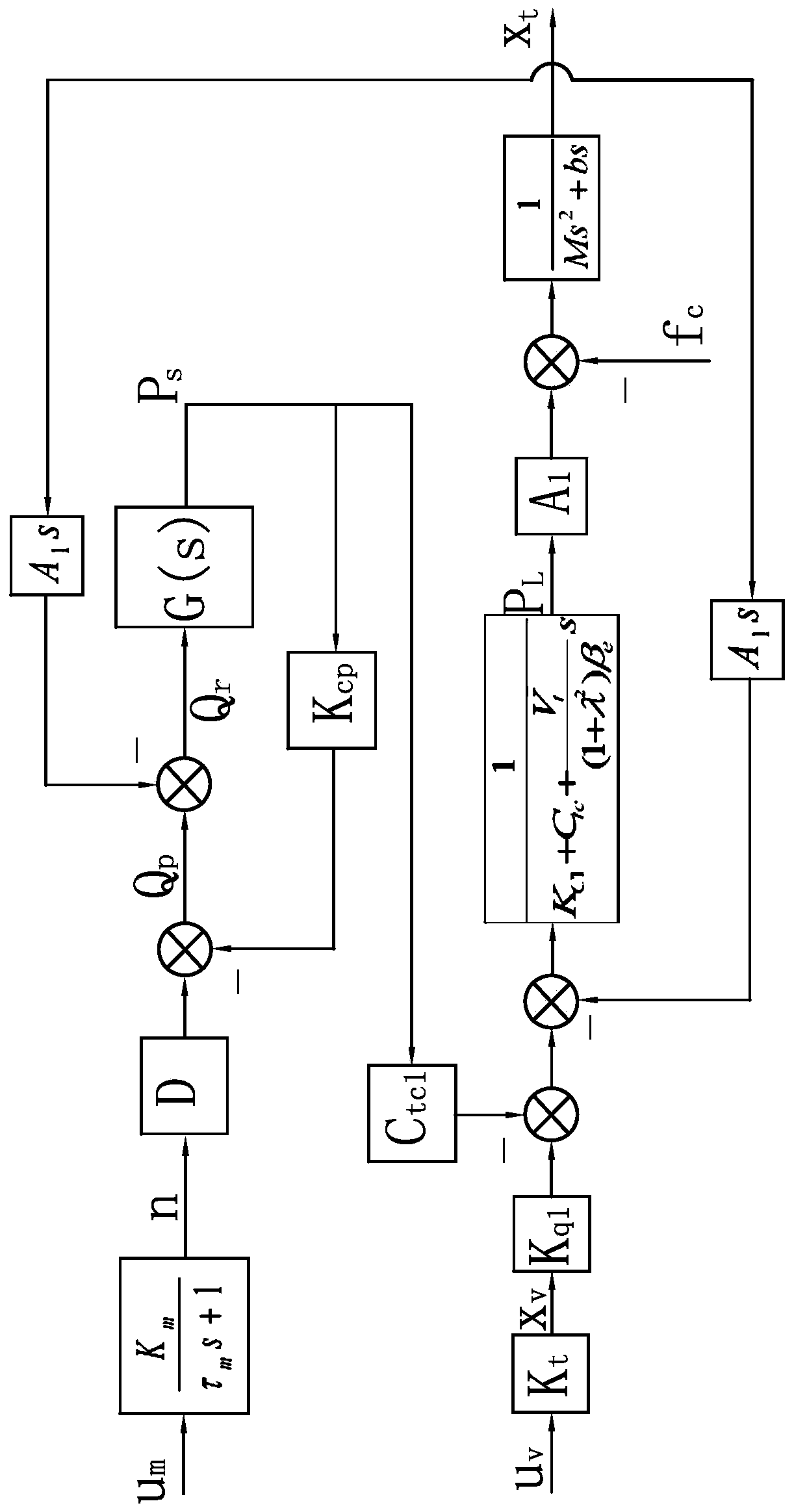

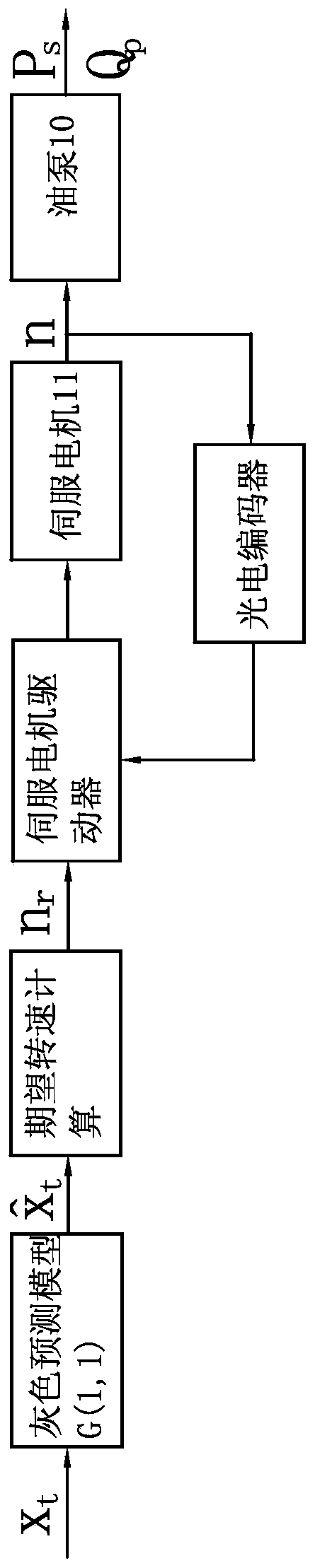

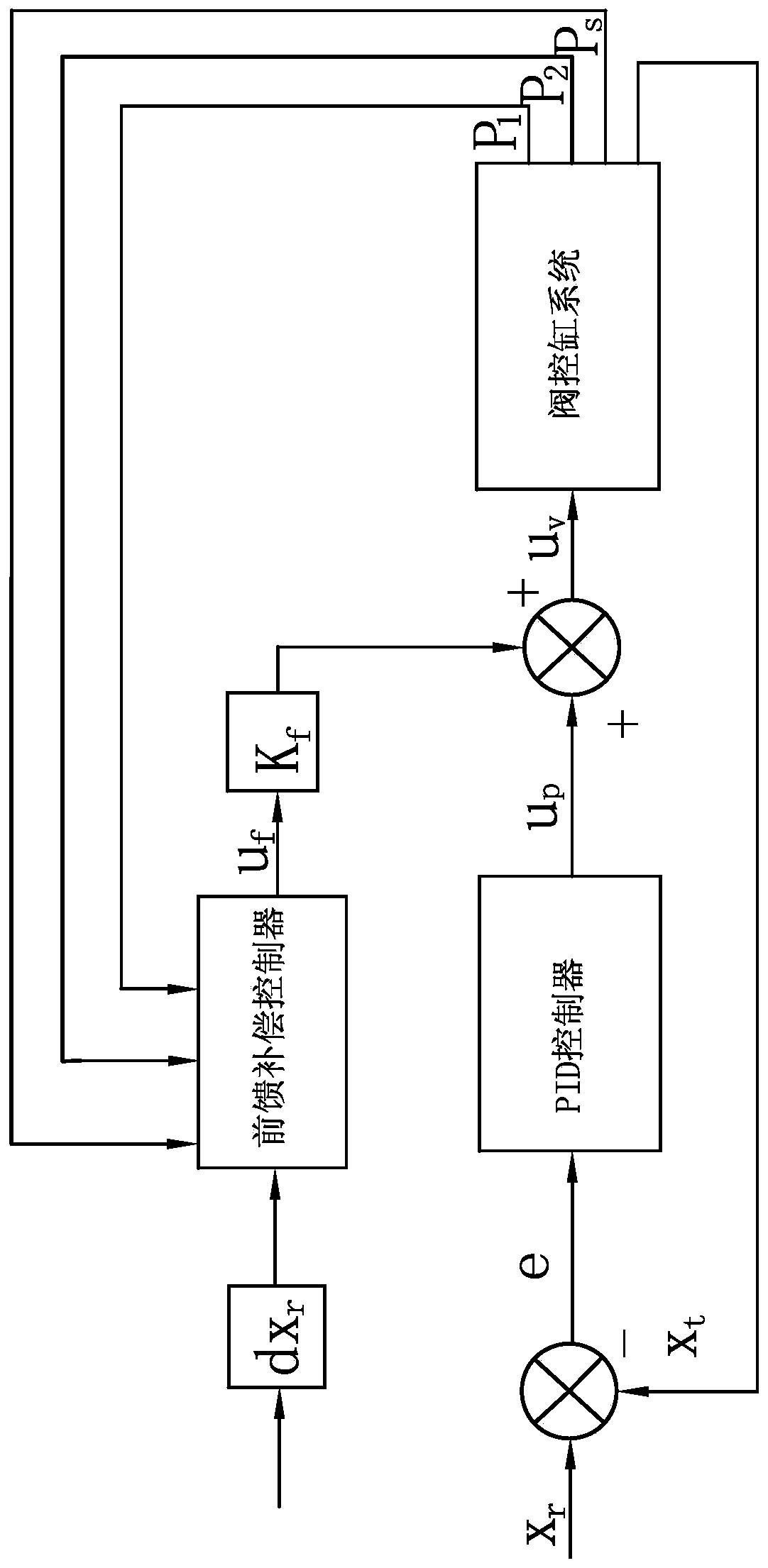

[0079] Such as Figure 1-3 As shown, the pump valve cooperative control method for prestressed intelligent tensioning equipment includes the following steps:

[0080] Build a model of the pump-valve coordinated control system;

[0081] The pump control part of the model of the pump-valve cooperative control system adopts the load flow prediction control algorithm, and obtains the predicted value of the displacement of the hydraulic cylinder by establishing the gray prediction model G(1,1) Then get the predicted value of the hydraulic cylinder speed by differentiation, and calculate the predicted value Q of the load flow L , according to the predicted value Q of the load flow L Obtain the predicted value Q of the output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com