Metal belt type continuously variable transmission with symmetrical-moving conical discs

A continuously variable transmission, metal belt technology, applied in the direction of transmission, components with teeth, transmission control, etc., can solve the problems of less than expected fuel saving effect, no engine benefit, large loss of CVT efficiency, etc. , to achieve stable and reliable system operation, reduce energy consumption, improve transmission efficiency and parts life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

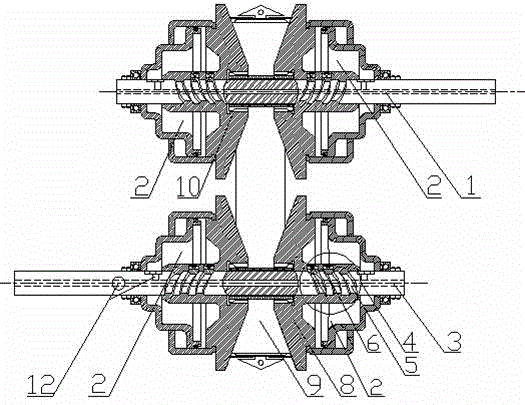

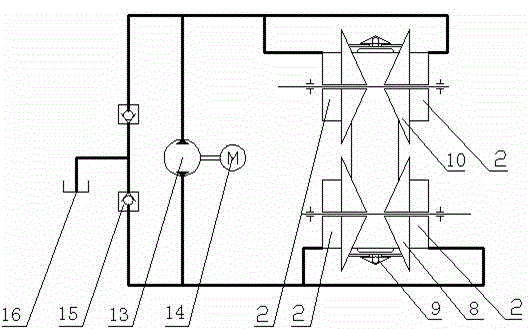

[0021] Such as figure 1 As shown, the cone-disc symmetrically moving metal belt type continuously variable transmission includes input shaft 1, output shaft 3, driving cone 10, driven cone 8, metal V-belt 9, cam pressurizing device 4 and pump-controlled closed hydraulic pressure transmission system. The driving cone 10 is installed on the input shaft 1 , and the driven cone 8 is installed on the output shaft 3 .

[0022] Among them, both the driving cone 10 and the driven cone 8 are composed of two movable cones, and the two movable cones on the same shaft are connected by a coupling structure or a connecting piece and are slidably matched with the corresponding shaft, and the metal V-belt 9 sleeves on the two movable cones on the input shaft 1 and the two movable cones on the output shaft 3. An oil cylinder 2 is respectively arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com