High-stability dyeing treatment method for wood

A technology with high stability and treatment method, applied in the direction of wood treatment, wood treatment details, radiation/wave wood treatment, etc., can solve the problems of poor coloring effect, affecting quality and life, and achieve good appearance, not easy to fade, with reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

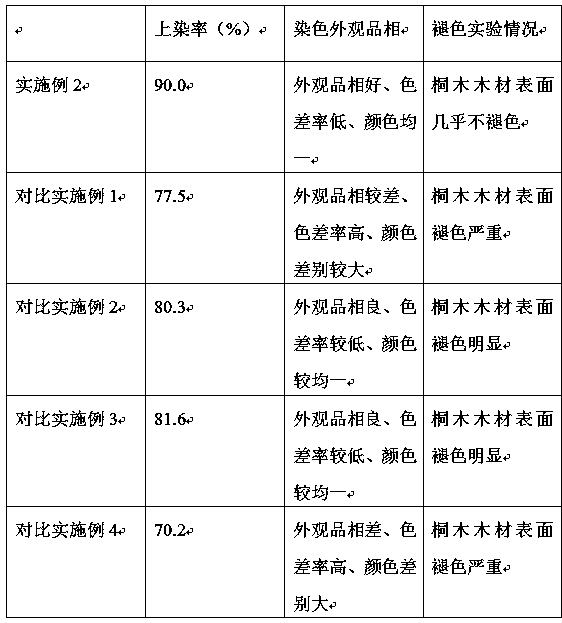

Examples

Embodiment 1

[0028] A high-stability dyeing treatment method for wood includes the following steps:

[0029] (1) Cleaning treatment:

[0030] First use compressed air to blow off the sawdust impurities on the surface of the wood, then rinse the wood with clean water, dry it for later use;

[0031] (2) Irradiation treatment:

[0032] Put the wood treated in step (1) into the irradiation box and use 60 Co-γ rays irradiate the wood and take it out for use after 1 hour;

[0033] (3) Spray coating treatment of modified liquid:

[0034] Spray the modified solution prepared in advance on the wood surface treated in step (2), and then put it in a drying oven at a temperature of 80°C for 2 hours and take it out for use;

[0035] (4) Dyeing treatment:

[0036] The wood treated in step (3) is immersed in the stain, and ultrasonic treatment is performed at the same time. The wood is taken out after 1 hour, and finally dried to a water content of 10-15%.

[0037] Further, as described in step (2) 60 The total dose o...

Embodiment 2

[0047] A high-stability dyeing treatment method for wood includes the following steps:

[0048] (1) Cleaning treatment:

[0049] First use compressed air to blow off the sawdust impurities on the surface of the wood, then rinse the wood with clean water, dry it for later use;

[0050] (2) Irradiation treatment:

[0051] Put the wood treated in step (1) into the irradiation box and use 60 Co-γ rays irradiate the wood and take it out for use after 1.1h;

[0052] (3) Spray coating treatment of modified liquid:

[0053] Spray the pre-prepared modification solution on the wood surface treated in step (2), and then put it in a drying oven at a temperature of 80~85°C for 2.5 hours and take it out for use;

[0054] (4) Dyeing treatment:

[0055] The wood treated in step (3) is immersed in the stain, and ultrasonic treatment is performed at the same time. The wood is taken out after 1.6 hours, and finally dried to a water content of 10-15%.

[0056] Further, as described in step (2) 60 The total dos...

Embodiment 3

[0066] A high-stability dyeing treatment method for wood includes the following steps:

[0067] (1) Cleaning treatment:

[0068] First use compressed air to blow off the sawdust impurities on the surface of the wood, then rinse the wood with clean water, dry it for later use;

[0069] (2) Irradiation treatment:

[0070] Put the wood treated in step (1) into the irradiation box and use 60 Co-γ rays irradiate the wood and take it out for use after 1.2h;

[0071] (3) Spray coating treatment of modified liquid:

[0072] Spray the modified solution prepared in advance on the wood surface treated in step (2), and then put it in a drying oven at a temperature of 85°C for 3 hours and take it out for use;

[0073] (4) Dyeing treatment:

[0074] The wood treated in step (3) is immersed in the staining agent, and ultrasonic treatment is performed at the same time, the wood is taken out after 2 hours, and finally dried to a water content of 10-15%.

[0075] Further, as described in step (2) 60 The tota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com