Long-acting antibacterial finishing method for rabbit hair fabric, based on glutaraldehyde crosslink

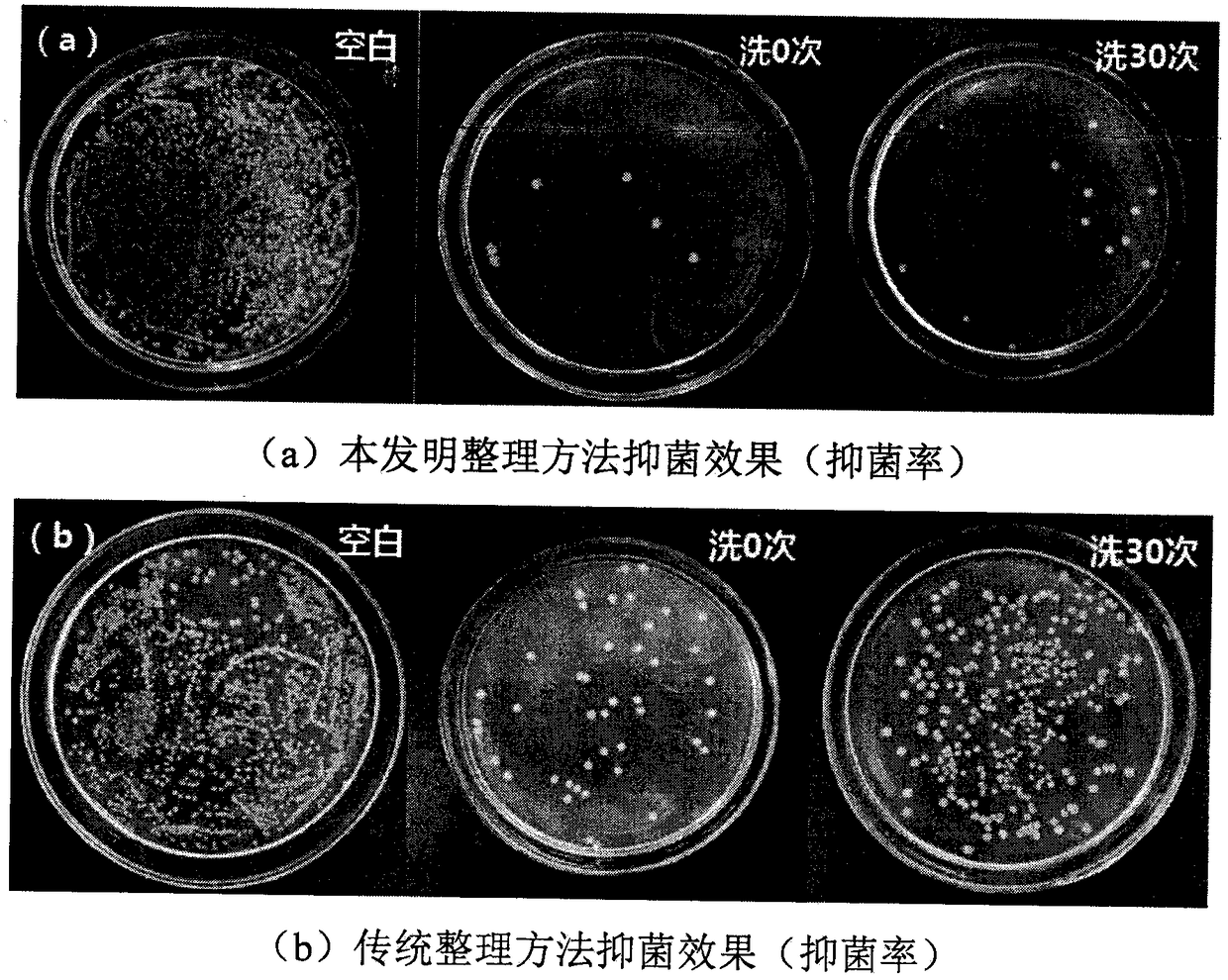

A glutaraldehyde cross-linking, antibacterial finishing technology, applied in fiber treatment, animal fiber, biochemical fiber treatment and other directions, can solve the lack of antibacterial long-term effect (washability, fabric wearability decline, rabbit wool fabric antibacterial It can achieve the effect of high-efficiency broad-spectrum antibacterial property, low cost and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The first way: put 2g of rabbit hair fabric into 10mL of 3% chitosan solution (bath ratio 1:5), shake at a low speed in a constant temperature water bath at 30°C. Soak the head for 30 minutes and remove it, and the excess rate of head rolling is 50%. Second dipping for 30 minutes to remove, second rolling rate of 100%.

[0041] Second step: Put the first finishing fabric into 10 mL of 5% glutaraldehyde solution (bath ratio 1:5), shake at a low speed for 1 hour in a constant temperature water bath at 50°C. Then pull out the rolling solution, the excess rolling rate is 150%, wash once with hot water at 50°C, wash twice with cold water, air-dry, and finish finishing.

[0042] The evaluation of the antimicrobial activity of the finished fabrics was carried out in accordance with "GB / T 20944.3-2008 Antibacterial Performance Evaluation of Textiles Part III: Oscillating Method".

Embodiment 2

[0044] The first step: put 2g of rabbit hair fabric into 10mL of 3% chitosan solution (bath ratio 1:5), shake at a low speed in a constant temperature water bath at 30°C. Soak the head for 30 minutes and remove it, and the excess rate of head rolling is 50%. Second dipping for 30 minutes to remove, second rolling rate of 100%.

[0045]Second step: Put the first finishing fabric into 10 mL of 2.5% glutaraldehyde solution (bath ratio 1:5), and shake at a low speed for 1 hour in a constant temperature water bath at 50°C. Then pull out the rolling solution, the excess rolling rate is 150%, wash once with hot water at 50°C, wash twice with cold water, air-dry, and finish finishing.

[0046] The evaluation of the antimicrobial activity of the finished fabrics was carried out in accordance with "GB / T 20944.3-2008 Antibacterial Performance Evaluation of Textiles Part III: Oscillating Method".

Embodiment 3

[0048] The first step: put 2g of rabbit hair fabric into 10mL of 2% chitosan solution (bath ratio 1:5), shake at a low speed in a constant temperature water bath at 30°C. Soak the head for 30 minutes and remove it, and the excess rate of head rolling is 50%. Second dipping for 30 minutes to remove, second rolling rate of 100%.

[0049] Second step: Put the first finishing fabric into 10 mL of 5% glutaraldehyde solution (bath ratio 1:5), shake in a constant temperature water bath at 50°C for 1 hour at a low speed. Then pull out the rolling solution, the excess rolling rate is 150%, wash once with hot water at 50°C, wash twice with cold water, air-dry, and finish finishing.

[0050] The evaluation of the antimicrobial activity of the finished fabrics was carried out in accordance with "GB / T 20944.3-2008 Antibacterial Performance Evaluation of Textiles Part III: Oscillating Method".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com