Urea-assisted SAGD feasibility evaluation experiment device and method

A feasible, urea technology, applied in earth-moving drilling, production fluids, wellbore/well components, etc., can solve problems affecting SAGD development effect and recovery factor, reducing reservoir permeability and porosity, reservoir damage, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

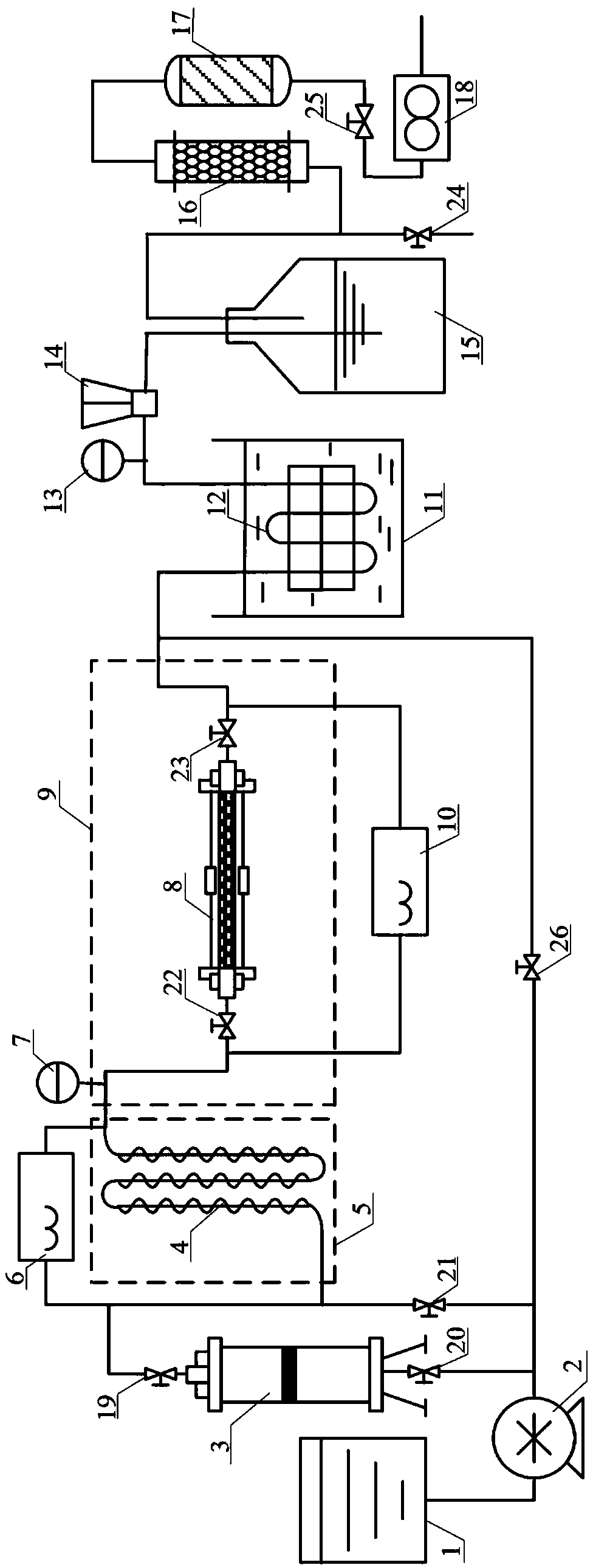

[0069] This embodiment provides a urea-assisted SAGD feasibility evaluation experimental device, such as figure 1 As shown, the device includes:

[0070] Urea solution injection unit, pipeline formation simulation unit, product recovery unit and temperature and pressure control unit;

[0071] The urea solution injection unit includes a piston container 3;

[0072] The pipeline formation simulation unit includes a heating coil 4 and a sand filling pipe 5;

[0073] The product recovery unit includes a dilute sulfuric acid absorption bottle 15, a gas drying pipe 16 and a gas flow meter 18;

[0074] The temperature and pressure control unit includes a first pressure gauge 7, a second pressure gauge 13, a first thermostat 5, a second thermostat 9 and a back pressure valve 14;

[0075] Piston container 3 is used to fill urea solution; piston container 3, heating coil 4, first pressure gauge 7, sand filling pipe 8, second pressure gauge 13, back pressure valve 14, dilute sulfuric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com