Infrared optical material impurity test method

A technology of infrared optical materials and testing methods, applied in the field of optical material impurity testing, can solve problems such as shortening testing time, and achieve the effects of reducing costs, real testing results, and fast testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

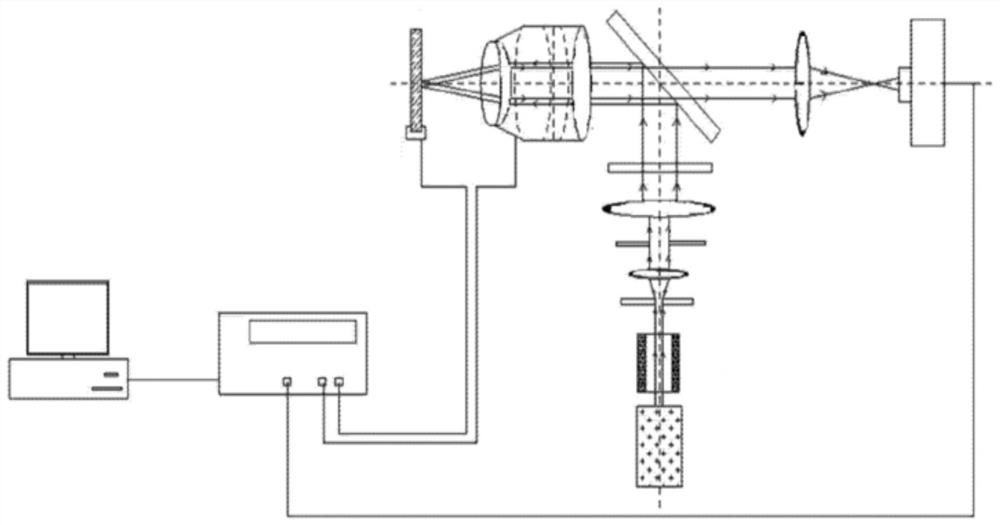

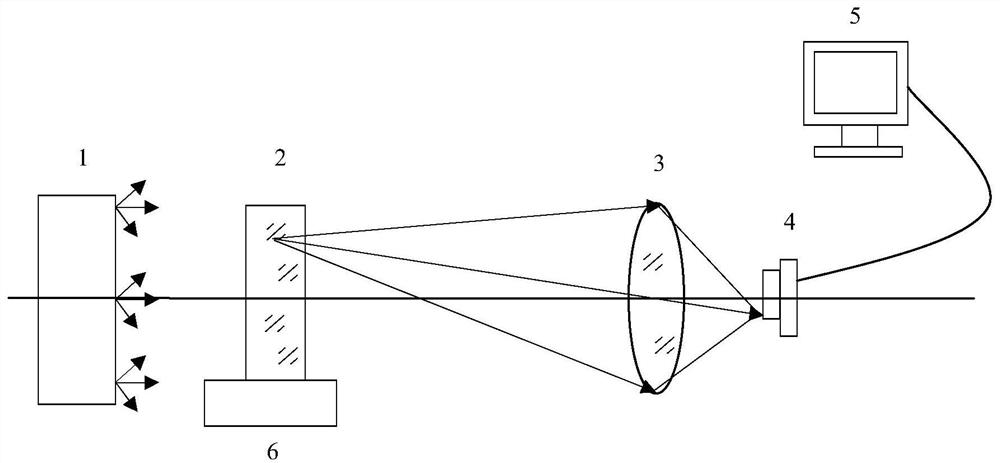

[0042] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

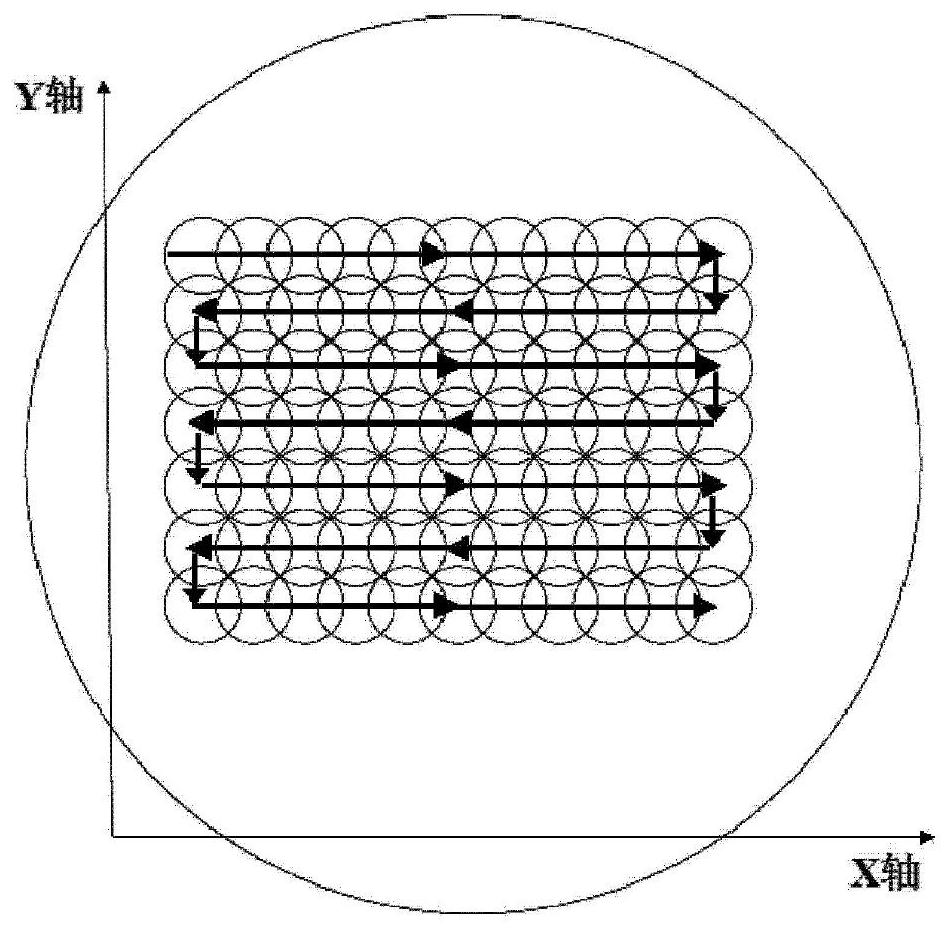

[0043] The inventors of the present invention found that the impurities in the infrared optical material can be imaged once by using the depth of field of the infrared camera system, and the actual possession of impurities in the optical material can be obtained comprehensively, so that the impurity test of the infrared optical material is simplified and real . The proposal of this invention is based on two basic points, one is to have a deep understanding of the characteristics and performance relationship of the optical system imaging (the performance relationship of the optical system is mainly the relationship between resolution, depth of field, F number, etc.), and the other is Have a deep understanding of the actu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com