Integral separated PID control method

A technology of integral separation and control method, applied in the field of automatic control, can solve problems such as excessive size, and achieve the effects of good measurement noise, avoid noise amplification, and measurement noise suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

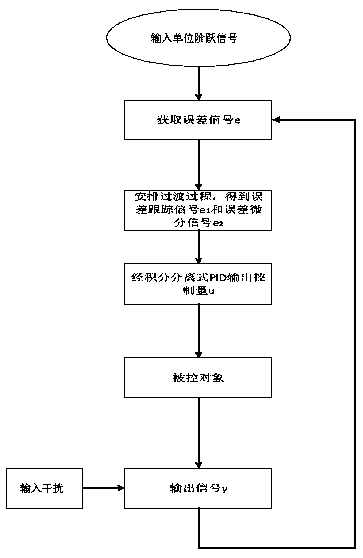

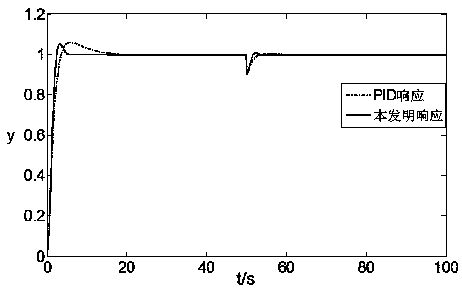

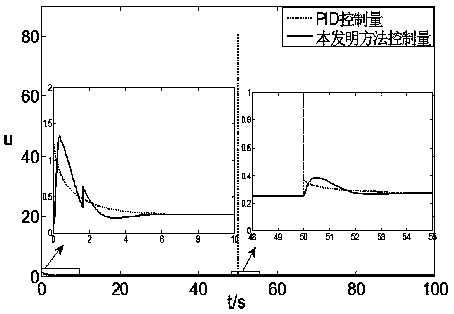

[0048] Such as figure 1 with figure 2 As shown, an integral-separation PID control method, the controlled object is assumed to be a second-order object, and its transfer function form is:

[0049]

[0050] where K is the system gain, T 1 and T 2 is the system time constant;

[0051] Its control method comprises the following steps;

[0052] S1: Design feedback loop filter TD2, input and output signal y(t), output filter signal y 0 (t);

[0053] S2: Design the tracking differentiator TD1, input the error signal e(t), and output the error tracking signal e of e(t) 1 (t) and error differential signal e 2 (t);

[0054] S3: Design the integral separation link, input the error tracking signal e 1 (t), the output integral control component u ki (t);

[0055] S4: Design the proportional link and the differential link, respectively input the error tracking signal e 1 (t) and error differential signal e 2 (t), output proportional control component u kp (t) and differenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com