Cheese quality improver and preparation method and applications thereof

A quality improver and cheese technology, applied in the field of food processing, can solve problems such as food safety problems, hypercalcemia, alkalosis, shortening of curdling time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides a kind of cheese quality improver by differential centrifugal method, adopt following steps to produce this cheese quality improver:

[0037] (1) Centrifuge fresh milk at 4,000g for 30 minutes to remove the upper layer of fat and collect skim milk;

[0038] (2) Ultracentrifuge the skimmed milk at 40,000g for 1 hour to remove the precipitated casein micelles with large particle size in the lower layer and collect the supernatant;

[0039] (3) Take the supernatant and ultracentrifuge at 80,000g for 2 h, discard the upper layer and collect the precipitate in the centrifuge tube;

[0040] (4) Take the precipitate, vacuum freeze-dry for 48 h, pulverize, sieve with 200 mesh, and bag it for later use.

Embodiment 2

[0042] This embodiment provides a membrane separation method cheese quality improver, which is produced by the following steps:

[0043] (1) Centrifuge fresh milk at 4,000g for 30 minutes to remove the upper layer of fat and collect skim milk;

[0044] (2) Take the skim milk and pass it through a microfiltration device with a filter membrane with a pore size of 0.2 μm, collect the permeate that can pass through the membrane, and discard the casein micelles with large particle sizes trapped on the filter membrane;

[0045] (3) Take the collected permeate through a microfiltration device with a filter membrane with a pore size of 0.1 μm, and collect casein micelles with small particle sizes trapped on the filter membrane;

[0046] (4) Vacuum freeze-dry the collected casein micelles with small particle size for 48 h, pulverize, sieve with 200 mesh, and bag them for later use.

Embodiment 3

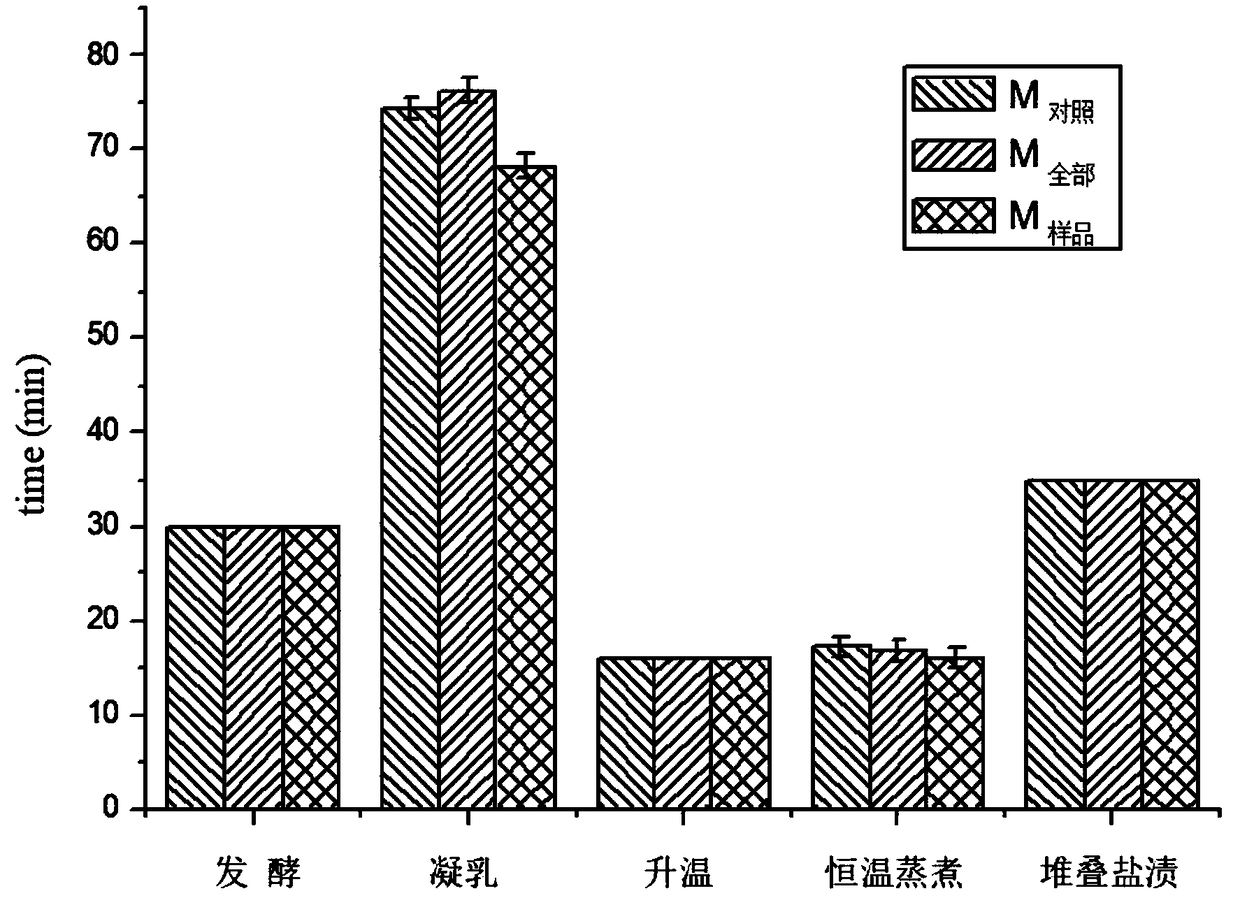

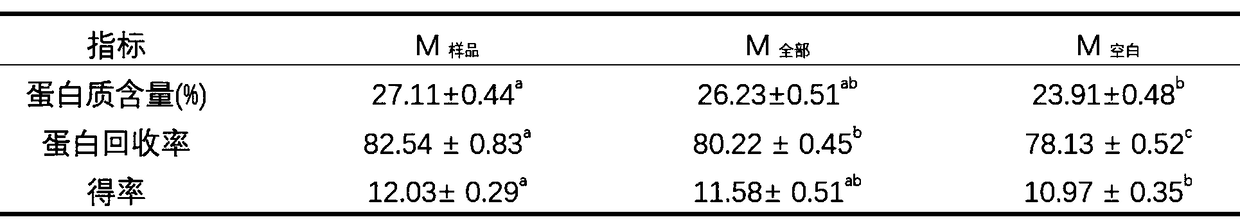

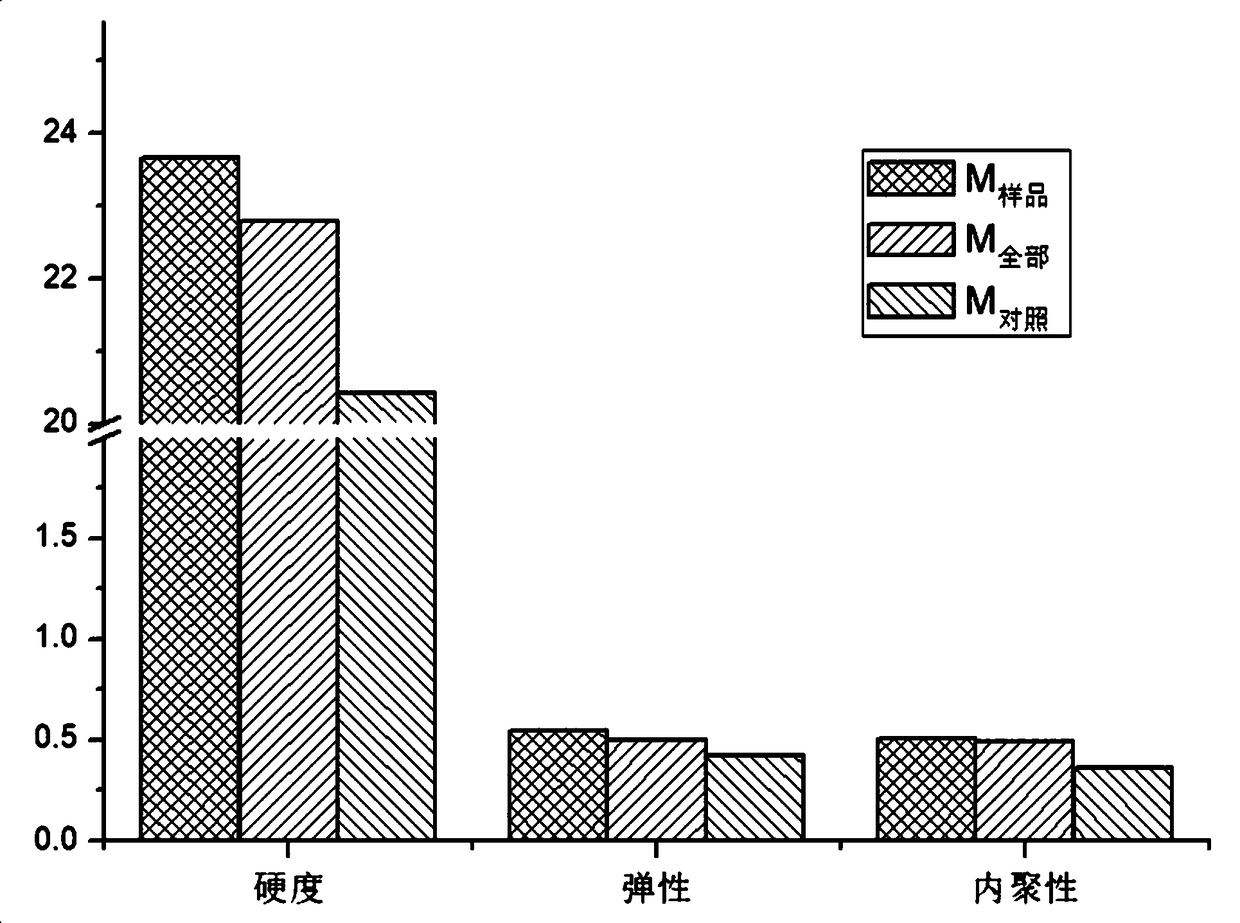

[0048] The present embodiment provides a kind of cheese production method, comprises the steps:

[0049] (1) mixed milk, (2) pasteurization, (3) cooling, (4) addition of starter culture, (5) addition of rennet, (6) curdling, (7) curd cutting, stirring and heating, (8) Reheating, (9) Draining whey, (10) Stirring and adding salt, (11) Brewing, (12) Pressing, (13) Vacuum packaging.

[0050] in,

[0051] Step (1) Mixed milk: Add the cheese quality improver to the milk in an amount of 0.5% (w / v), and stir to fully dissolve it.

[0052] Step (2) Pasteurization: Insulate and sterilize at 62-65°C for 30 minutes.

[0053] Step (4) Add starter: cool the sterilized mixed milk to 32°C, add 0.004% (w / v) starter to ferment to pH 6.5.

[0054] Step (5) Adding rennet: add rennet at an amount of 0.005% (w / v) to the end of curdling. The curdling time is defined as: the time from adding rennet to the time when the inclined raw milk does not flow, min.

[0055] Step (7) Curd cutting, stirrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com